9 Arc Welding Application

9.8 Arc Welding Management and Maintenance

9-67

149235-1CD

RE-CSO-A031

9.8.2 Editing the ARC WELD DIAGNOSIS Window

Operation Explanation

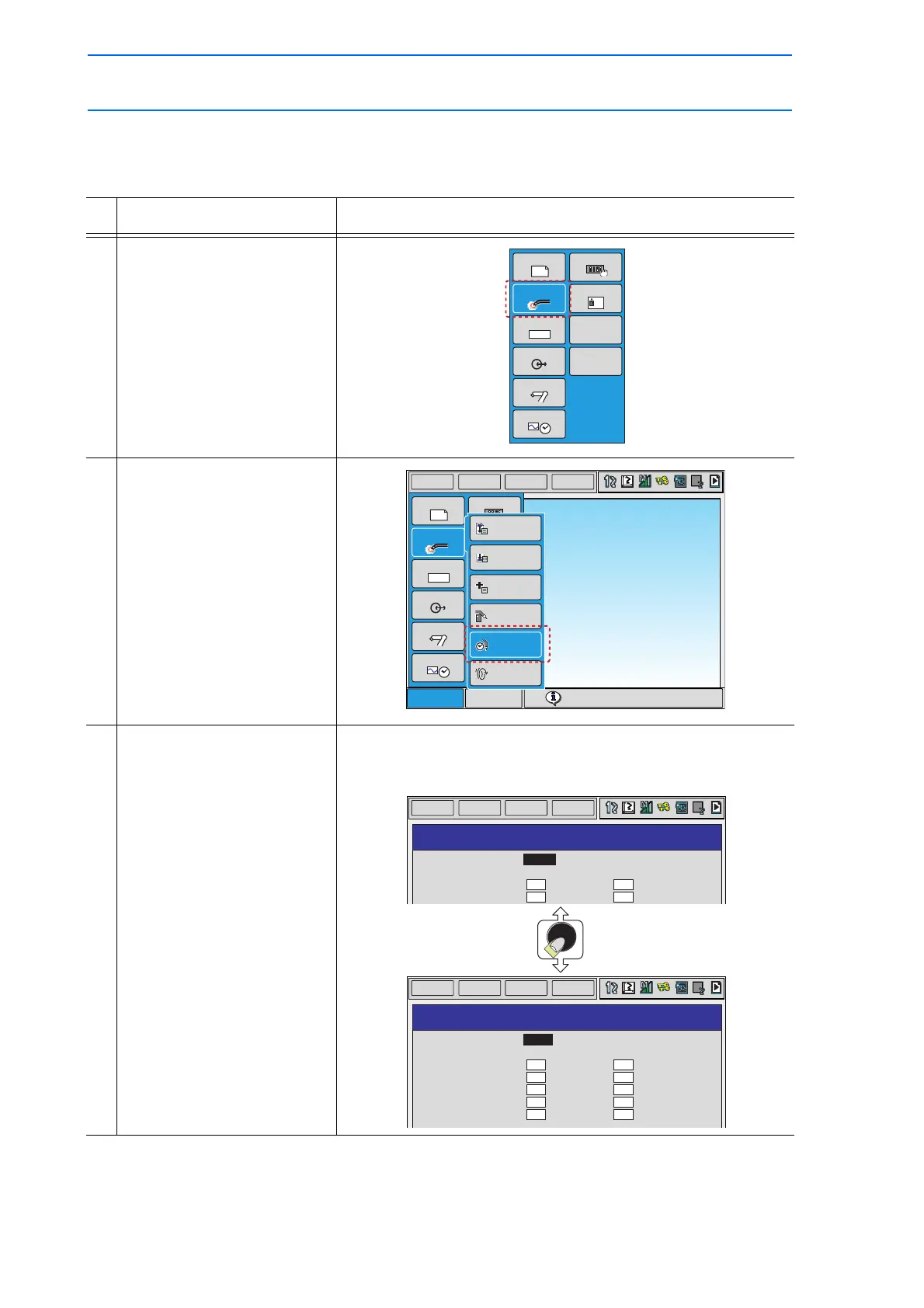

1 Select {ARC WELDING} under

the main menu.

2 Select {ARC WELD DIAG.}.

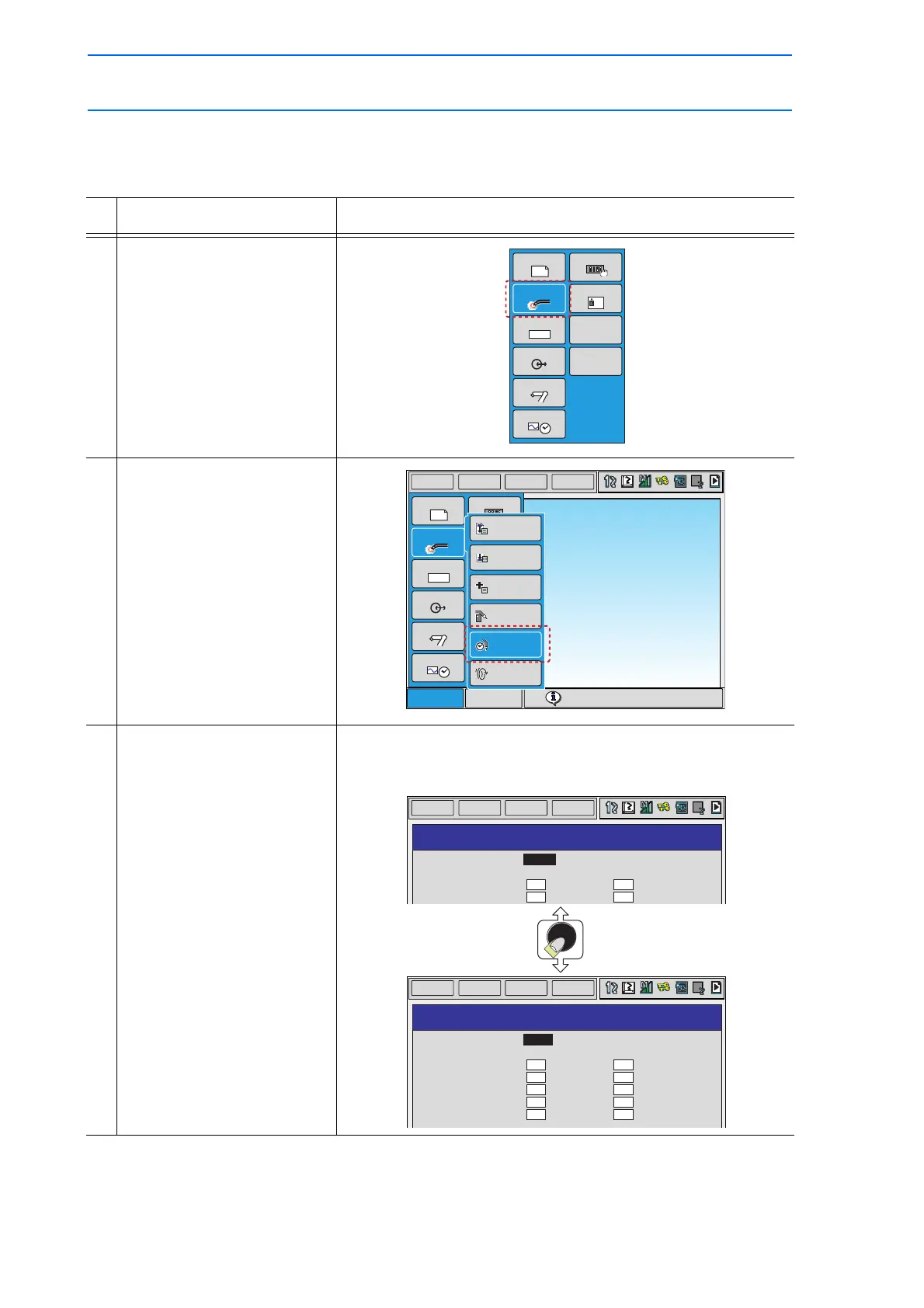

3 Line up the cursor with each

set item and press [SELECT]

to edit it.

<Setting the Work Continue Specification>

When [SELECT] is pressed, the setting alternates between

“CONT” and “STOP.”

JOB

DOUT

MOVE

END

IN/OUT

In Out

SYSTEM INFO

SETUP

VARIABLE

B001

ROBOT

PARAMETER

ARC WELDING

JOB

EDIT

DIPSLAY

UTILITY

Main Menu ShortCut

Set tool mass data

JOB

DOUT

MOVE

END

IN/OUT

In Out

SYSTEM INFO

VARIABLE

B001

ROBOT

PARAMETER

WEAVING

ARC END COND.

POWER SOURCE

COND.

ARC WELD DIAG.

ARC START COND.

ARC AUX COND.

ARC WELDING

DATA

EDIT

DISPLAY

UTILITY

DATA

EDIT

DISPLAY

UTILITY

ARC WELD DIAGNOSIS

NO.: 1/1

WORK CONTINUE

TIP REPLACE

NOZZLE CLEAN

: CONT

: 72 min

: 12 min

5

2

0

<ACCUM.> <SETTING>

180 min

30 min

10

10

10

ARC WELD DIAGNOSIS

NO.: 1/1

WORK CONTINUE

TIP REPLACE

NOZZLE CLEAN

RETRY

RESTART (ARC)

ANTI-STICK

: STOP

: 72 min

: 12 min

: 5 times

: 2 times

: 0 times

<ACCUM.> <SETTING>

180 min

30 min

10 times

10 times

10 times

SELECT

Loading...

Loading...