9 Arc Welding Application

9.3 Function Outlines

9-10

149235-1CD

RE-CSO-A031

9.3.6 Wire-stick Check Function

Anti-Stick Function

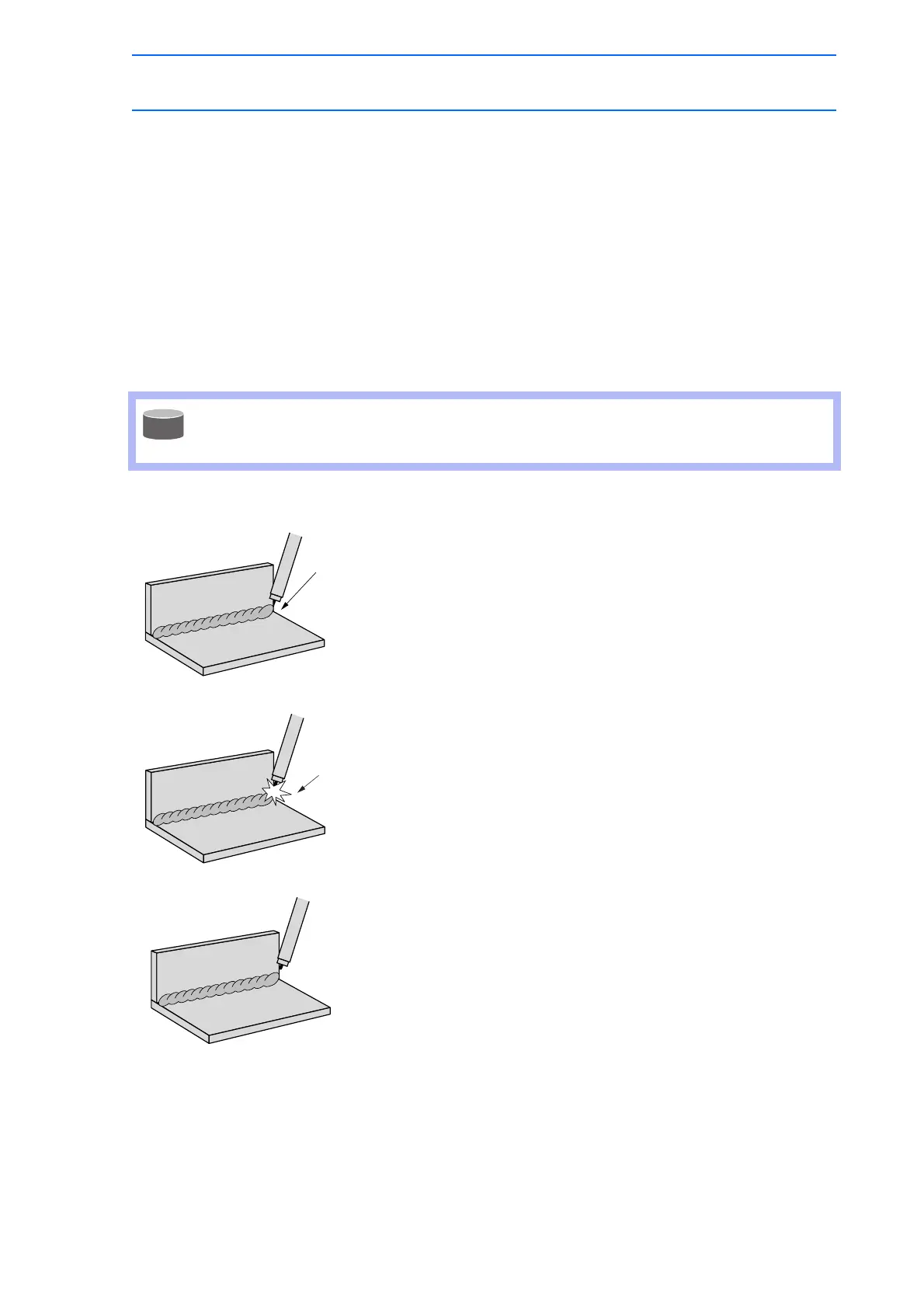

The wire may stick to the workpiece after welding is completed (). As an anti-stick process, the

Power Source temporarily increases the voltage at the end of welding(). After the anti-stick process,

a wire stick check is performed(). If the anti-stick process failed and a wire stick is detected, the

manipulator enters a hold status or performs the automatic sticking release process, depending on the

anti-stick condition specified.

Time required for the anti-stick process differs depending on the Power Sources. The anti-stick process

times for different Power Sources is registered in the Power Source characteristic file. The wire check

is performed after the anti-stick process time has elapsed.

Wire stick

“Wire stick” refers to the contact of the wire to the workpiece as observed after the arc-

OFF.

Welding ends. (Wire Stick

Occurrence)

Anti-stick Process

Wire Stick Check

Wire stick check is performed after

elapsing of the anti-stick process time

defined in the Power Source

characteristic file.

Anti-Stick Function

Voltage increased temporarily

as anti-stick process

Loading...

Loading...