9 Arc Welding Application

9.12 Power Source Condition File

9-87

149235-1CD

RE-CSO-A031

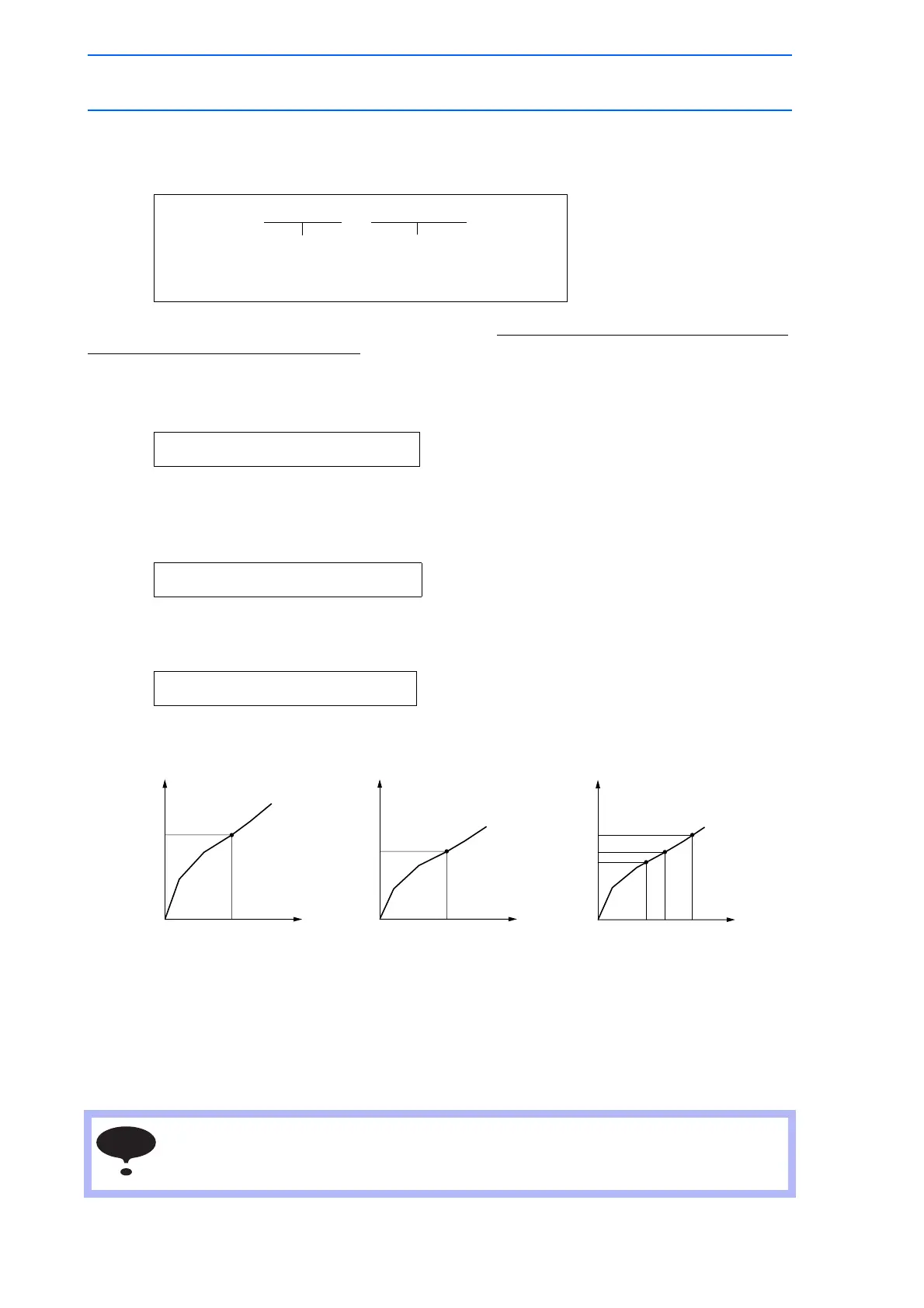

< Example >

An example is shown with the ARCON instruction.

If the welding current output is 250A, the welding voltage can be specified as follows:

With the voltage characteristics with the following Figure A, the above instruction causes the output of

7.5V control signal to the Power Source

If the welding current output value is changed to 220A, a minor correction to the ARCON instruction

causes the output of the control signal associated with 100% of the proper output value at 220A. (Fig.B)

Also note that a minor adjustment of the welding voltage can be instructed easily. (Fig.C)

e.g. The control signal is output 110% of the proper output value at 220A.

or

e.g. The control signal is output 94% of the proper output value at 220A.

This setting method enables easy adjustment without calculating the voltage output.

This method can be also applied to condition data files and instructions other than ARCON. Another

advantage is that a single welding job can be used with more than one Power Source with a synergic

power supply by changing the welder condition data file.

ARCON AC=250

Welding

current

250A

AVP=100

100% of proper output,

assuming the use of

synergic power supply.

ARCON AC=220 AVP=100 100% output

ARCON AC=220 AVP=110 110% output

ARCON AC=220 AVP=94 94% output

If welding current output is significantly different from the voltage characteristics

measurement used, voltage output may vary. Write the welding current value used for the

voltage characteristics measurement as a comment for reference.

0 7.5

(V)

(%)

100

94

110

0 7.5

Welding voltage reference value

Figure A

(V)

(%)

100

Voltage characteristics

at 250A

0 7.5

(V)

(%)

100

Welding voltage

output value

Welding voltage

output value

Welding voltage

output value

Voltage characteristics

at 220A

Welding voltage reference value

Figure B

Welding voltage reference value

Figure C

Loading...

Loading...