9 Arc Welding Application

9.12 Power Source Condition File

9-95

149235-1CD

RE-CSO-A031

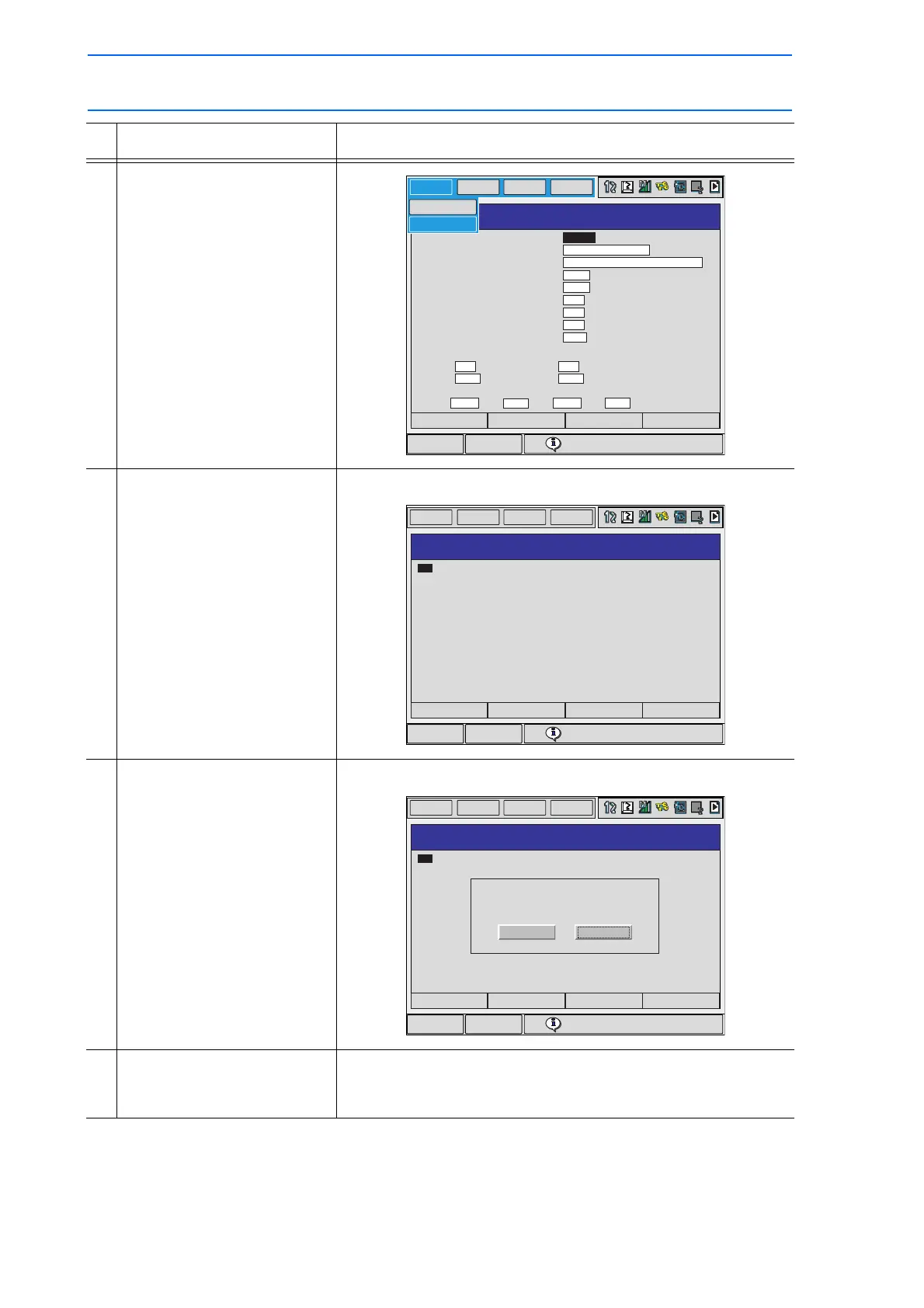

2 Select {POWER SOURCE

COND.}.

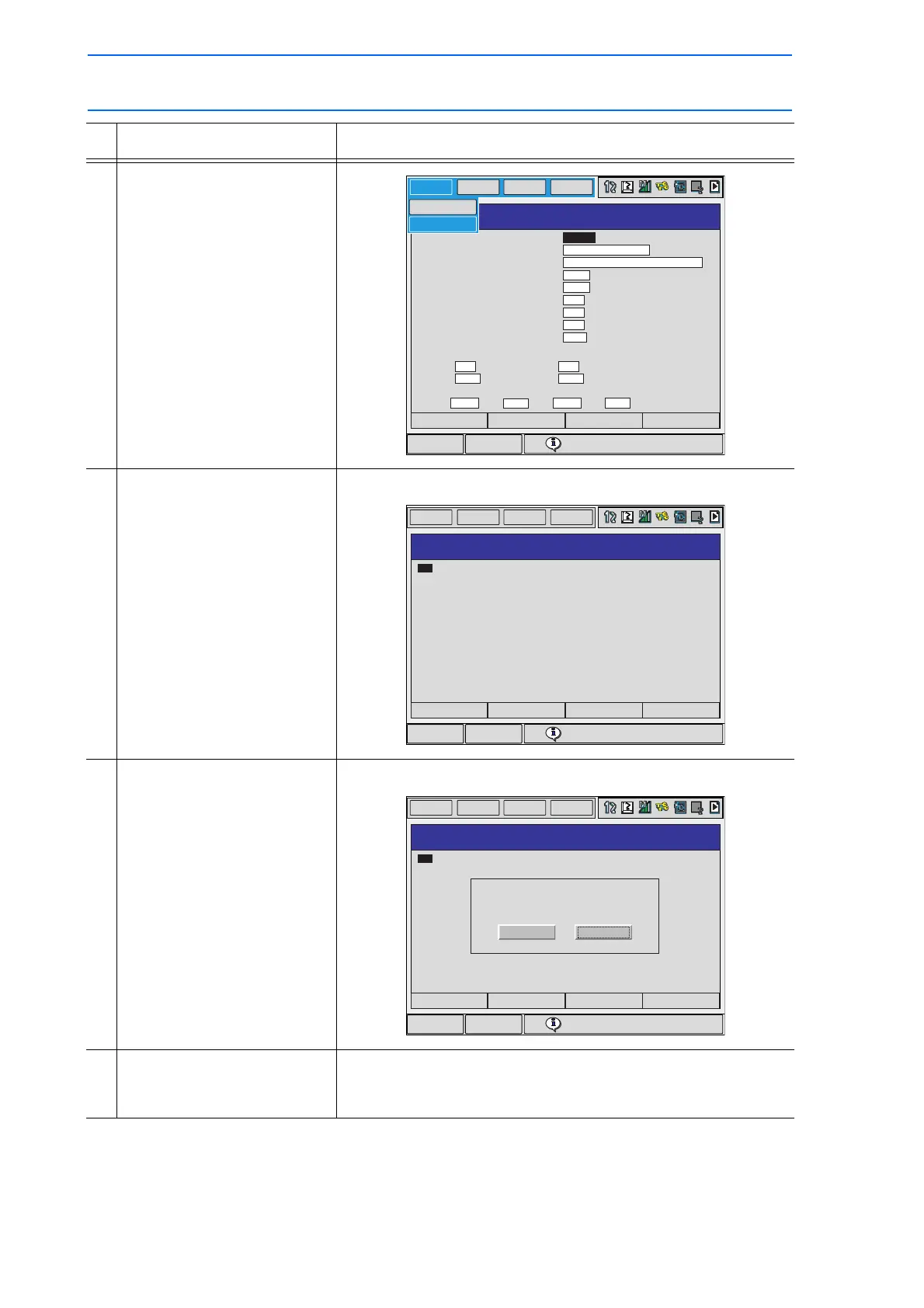

3 Select {WRITING} from

{DATA}

in the menu.

The user registered file list appears.

4 Select the Power Source

condition file number of the

data to be written.

The confirmation dialog box appears.

5 Select “YES” or “NO.” Select “YES” to register the Power Source condition file data.

Select “NO” to return to the POWER SOURCE CONDITION

window.

Operation Explanation

DATA

EDIT

DISPLAY

UTILITY

Main Menu ShortCut

!Turn on servo power

1/1

SETTING

POWER SOURCE NAME

COMM.

POWER SUPPLY

SHIELDING GAS

WIRE DIA.

WIRE STICKOUT

ANTI-STICKING

ARC FAILURE STOP

: DONE

: MOTOWELD-E350

: STC CONTROL NONE

: A/%

: CO2

: 0.1 mm

: 15 mm

: 0.1 sec

: 1.50 sec

50 0.00300.0001

<CURRENT OUTPUT CHAR.> <WELDING VOLTAGE OUTPUT CHAR.>

RANGE: + +

ADJUST: 1.00 1.00

NO. REF.(V) MEASURE (A) REF.(V) MEASURE (%)

WRITING

READING

DATA

EDIT

DISPLAY

UTILITY

Main Menu ShortCut

!Turn on servo power

USER INITIAL VALUE

NO. NAME POWER DIA. GAS

CO2

MAG

CO2

MAG

1.2

1.2

1.2

1.2

A/%

A/%

A/V

A/V

USER-1

USER-2

USER-3

USER-4

01

02

03

04

DATA

EDIT

DISPLAY

UTILITY

Main Menu ShortCut

!Turn on servo power

USER INITIAL VALUE

NO. NAME POWER DIA. GAS

CO2

MAG

CO2

MAG

1.2

1.2

1.2

1.2

A/%

A/%

A/V

A/V

USER-1

USER-2

USER-3

USER-4

01

02

03

04

Write data?

01 USER-1

YES NO

Loading...

Loading...