d-Color MF4003/MF3303

I SERVICE MODE > 9. System 1

I-41

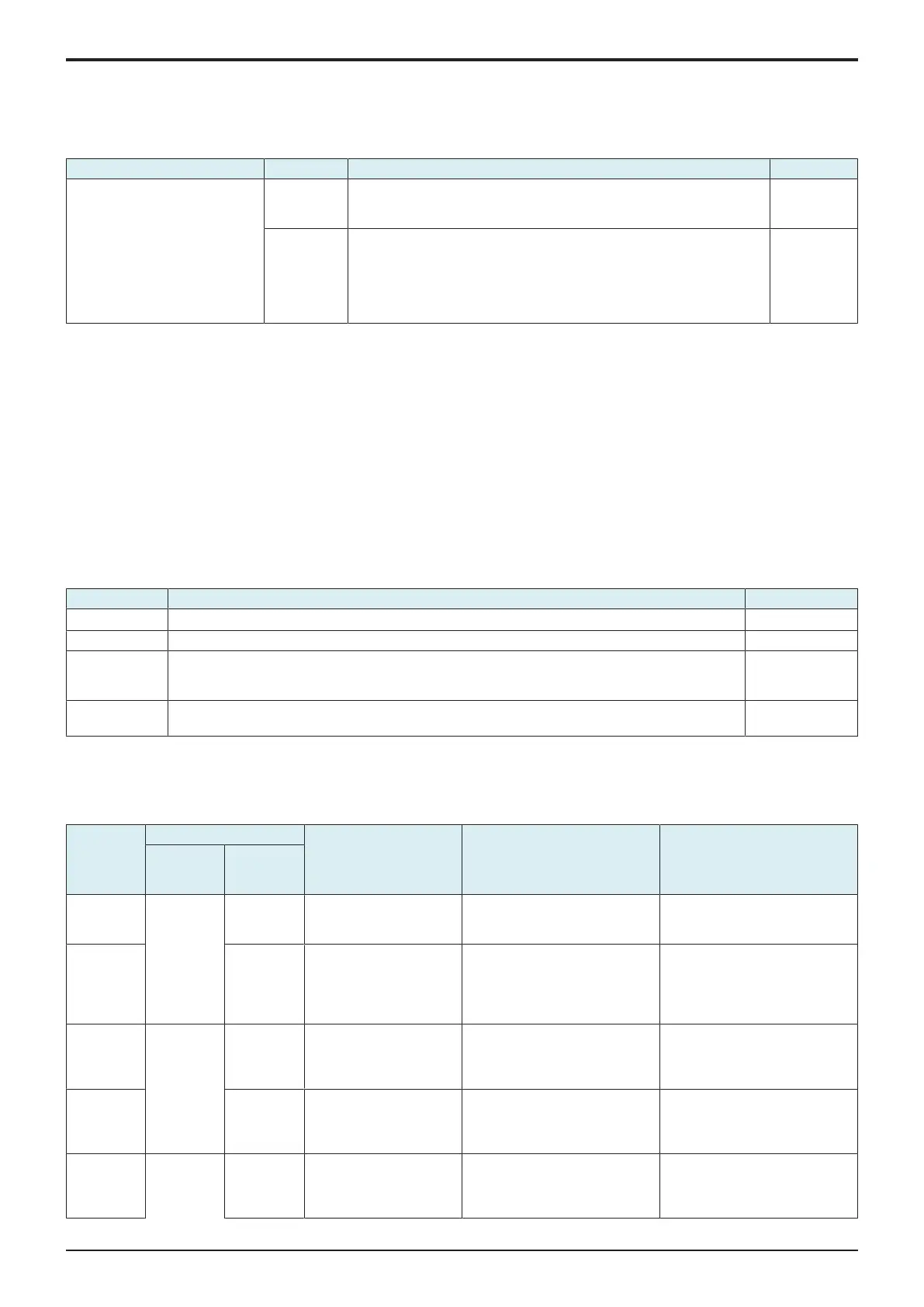

9.8Problem Unit Isolation Set.

• When a problem occurs, this function enables the use of the units or options that are not affected by separately controlling them and

isolating other units or options that have a problem.

NOTE

▪ The malfunction detection mechanism is not applied to units and options that are being isolated.

Setting item Setting value Contents Default setting

Tray 1

Tray 2

Tray 3

Set To normally isolate the units.

• This status will continue even after turning OFF and ON the main

power switch.

Unset No to isolate the units.

• When corresponding troubles occur, pressing the [Continue] key on

the warning screen, the user can isolate the problem units temporarily.

(*)

• This status will not continue after turning OFF and ON the power

switch.

○

• * For corresponding troubles, see “TROUBLE CODE.”

<Procedure>

1. Select the units or options to be set.

2. Specify [Set] or [Unset].

NOTE

▪ “Set” and “Unset” can be specified separately for each unit or option.

3. Touch [Apply].

4. The new setting becomes effective by turning the main power switch OFF and ON again.

9.9Warm-up

9.9.1Change Warm Up Time

• To change warm up completion time.

• Mode is changed to Mode 2 in case the paper gets curled significantly when black printing is conducted immediately after warm up at Mode

1.

• Mode is changed to Mode 3 or 4 in case the paper gets curled immediately after normal warm up or the curled paper causes paper jam,

paper exit failure, punch/staple/fold position failure or etc.

Setting item Contents Default setting

Mode 1 It makes the warm-up time for black print shortest.

○

Mode 2 The warm-up time for both black and color will be as specified value.

Mode 3 To prevent curling of the paper immediately after the warm-up, printing productivity is decreased by

PPM control.

The warm-up time for both black and color will be as specified value.

Mode 4 By having a longer warm-up time and warming up the fusing unit, curling of the paper immediately after

the warm-up can be prevented.

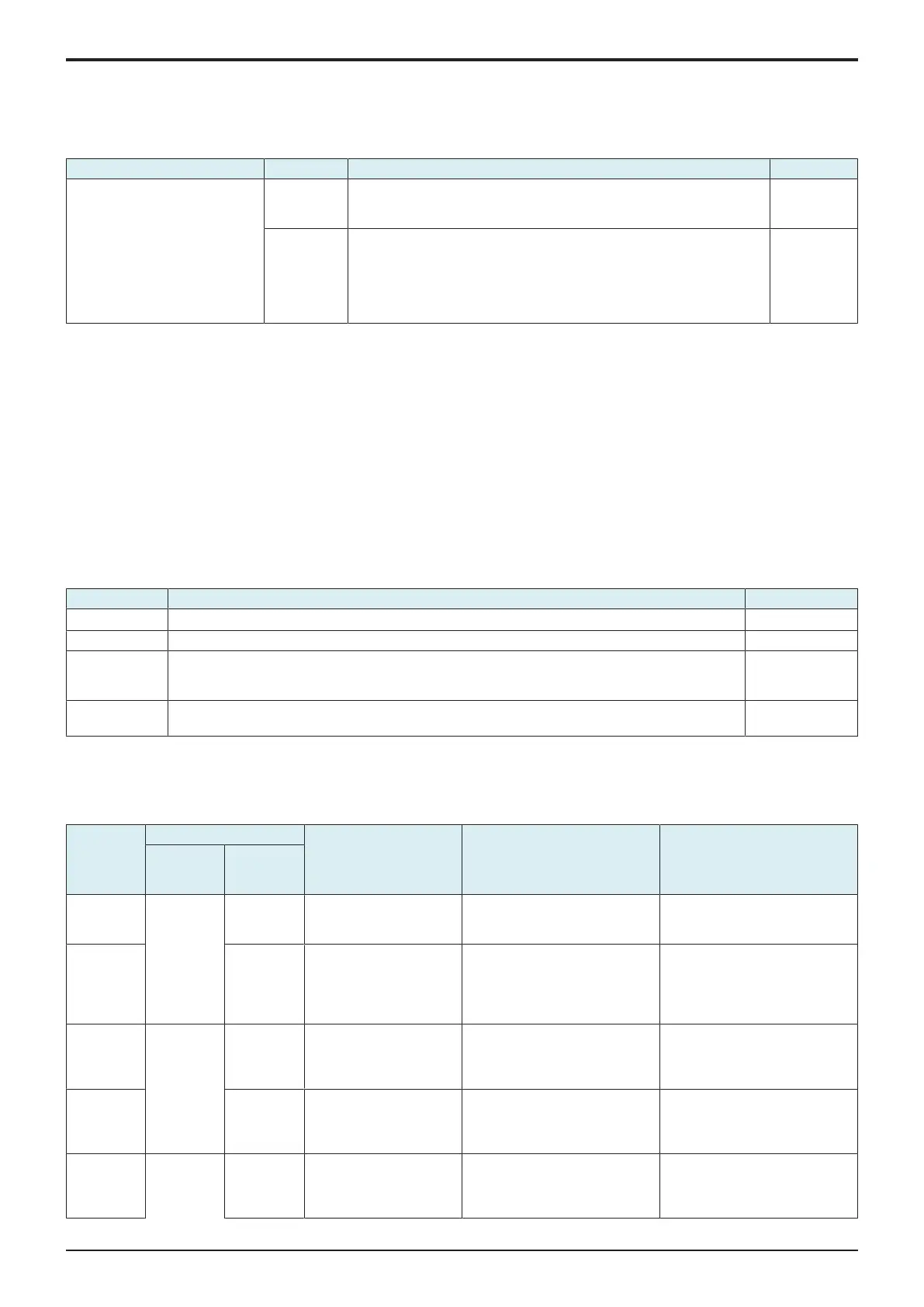

Fusing operation mode

• Warm-up related control can be changed by using [Warm Up] setting and [Choice of high humidity circumstance] setting in Engine FW

DipSW.

When the main power switch is turned on, the mode is defined according to each choice setting.

• The following table shows the features of each operation mode.

Operation

mode

Service Mode Target user Advantages Disadvantages

Warm-up Choice of

high humidity

circumstance

1

(Default

setting)

Mode 1 OFF Want to print quickly

Black usage rate is high

Makes warm-up time for black

shortest

Curling may occur in high humidity

2 ON Want to prevent curling

Black usage rate is high

Warm-up time for black is made

shortest except when in high

humidity

Decreases possibility curling

occurs in high humidity

Warm-up time is long in high

humidity (65 seconds or less)

3 Mode 2 OFF Want to print quickly

Color usage rate is high

Warm-up time is as specified value

or later

High productivity even in high

humidity

Curling may occur in high humidity

4 ON Want to prevent curling

Color usage rate is high

Warm-up time is as specified value

or later except in high humidity

Decreases possibility curling

occurs in high humidity

Warm-up time is long in high

humidity (65 seconds or less)

5 Mode 3 OFF Want to print quickly

Want to prevent curling

immediately after warm-up

Warm-up time is as specified value

or later

Decreases the curling in normal

circumstance

Productivity immediately after

warm-up decreases

Curling may occur in high humidity

Loading...

Loading...