d-Color MF4003/MF3303

L TROUBLESHOOTING > 16. IMAGE QUALITY PROBLEM

L-132

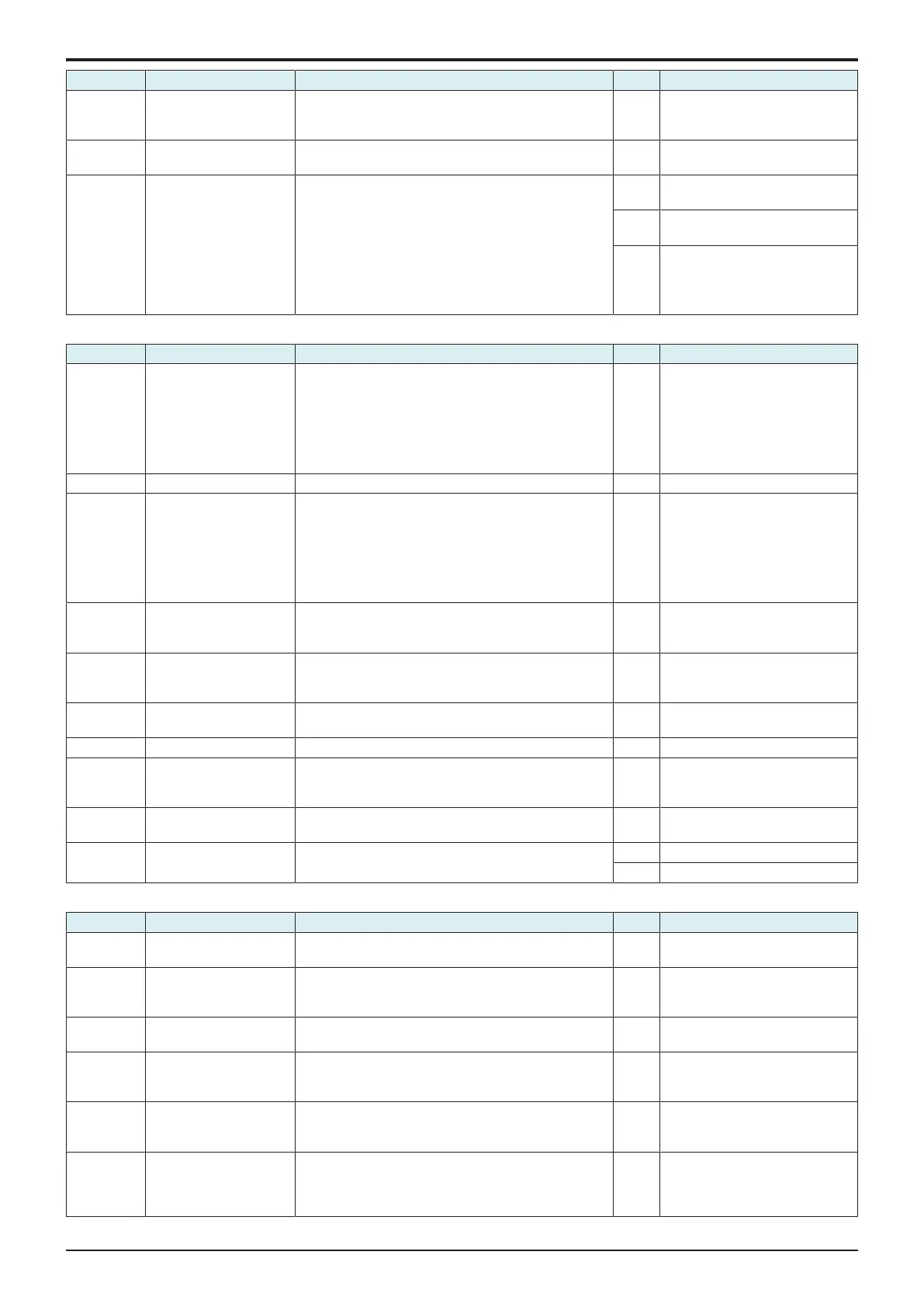

Step Section Check item Result Action

2 Service Mode ->

Stabilizer

Select [Service Mode] -> [Imaging Process Adjustment] -

> [Stabilizer] -> [Stabilization Only] and the image

trouble is eliminated.

NO Go to the next step.

3 Service Mode ->

Gradation Adjust

Select [Service Mode] -> [Imaging Process Adjustment] -

> [Gradation Adjust] and the image trouble is eliminated.

NO Go to the next step.

4 Image check • Select [Service Mode] -> [Test Mode] -> [Halftone

Pattern].

Select "SINGLE", "HYPER", "Error diffusion", "1-

Sided", "CMYK", and "Full Bleed", enter "64" for

Density, and load tray 2 with A4 paper. Press the

start key. This runs a print cycle for C, M, Y, and K

in that order.

• Check the image after printing to determine which

color causes the abnormal image.

1 to 3

colors

Go to the 1-color troubleshooting

procedure.

4

colors

Go to the 4-color troubleshooting

procedure.

None Go to scanner troubleshooting

procedure.

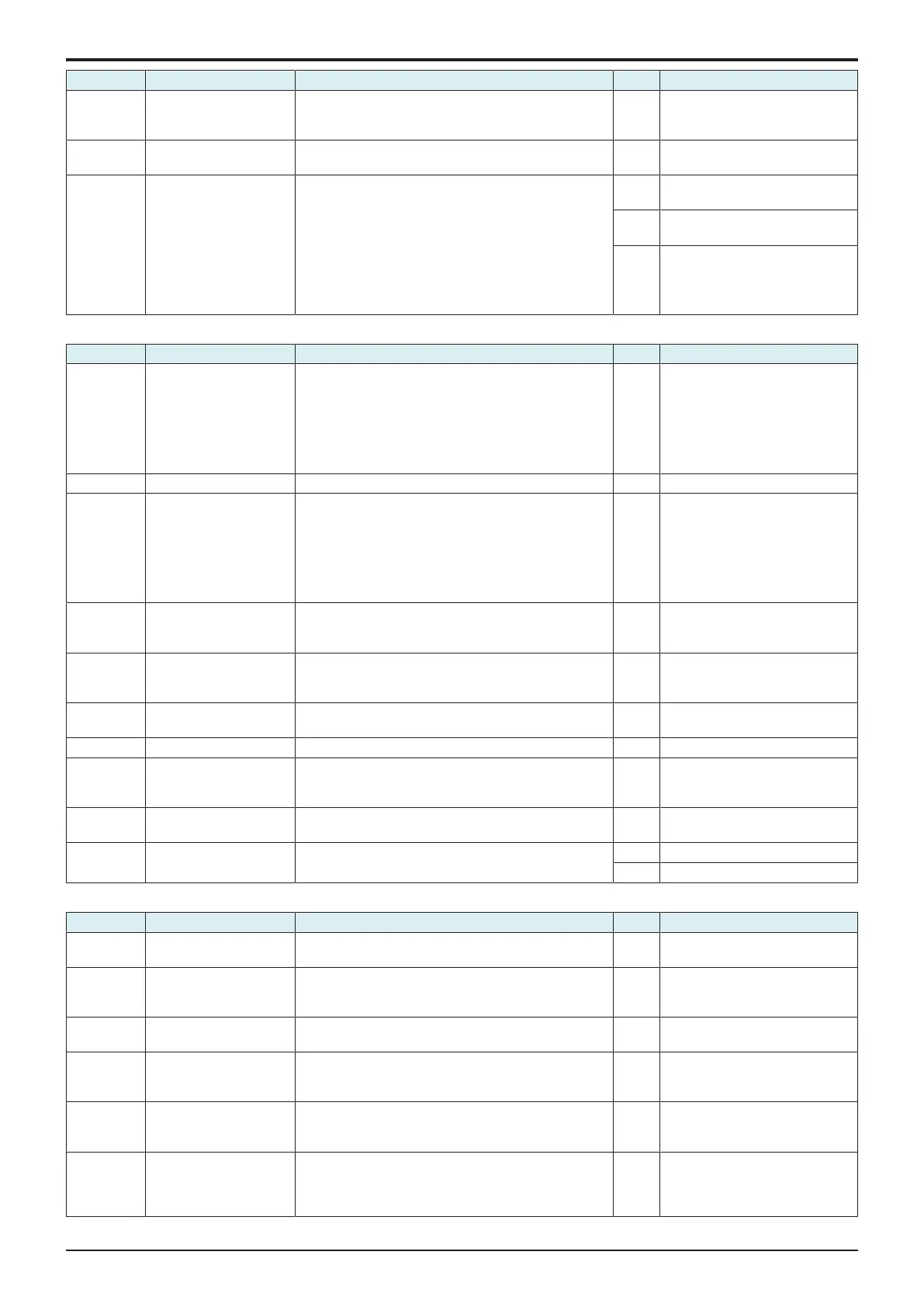

1-color troubleshooting procedure

Step Section Check item for the faulty color Result Action for the faulty color

1 Service Mode -> Table

Number

Select [Service Mode] -> [State Confirmation] -> [Table

Number]. The measured value is close to the standard

value.

• Developing bias: Vdc-C, Vdc-M, Vdc-Y, Vdc-K:

close to the standard value of -800 to 0

• Grid voltage: Vg-C, Vg-M, Vg-Y, Vg-K: close to the

standard value of -1600 to 0

NO • Check the high voltage unit

and the imaging unit for wiring

and connection.

• Replace the high voltage unit.

2 Write section Sharp white line or colored line is blurry. YES Clean the PH window.

3 Charging section Foreign matter on charging roller. YES Lightly wipe the surface clean of

foreign matter using hydro-wipe

(65AA-99##).

Note: Do not apply a strong force

to the surface of the charging

roller, as doing so can damage the

surface.

4 Photoconductor section There is a positive contact between the electrostatic

charger application terminals and the high voltage unit

connection terminals (Y: C4, M: C3, C: C2, K: C1).

NO Clean or correct the terminal.

5 Developing section There is a positive contact between the developing bias

application terminals and the high voltage unit

connection terminals (Y: B4; M: B3; C: B2; K: B1).

NO Clean or correct the terminal.

6 Photoconductor section Scratches on photoconductor. YES • Clean.

• Replace the imaging unit.

7 Photoconductor section Toner line or dirt on photoconductor. (improper cleaning) YES Replace the imaging unit.

8 1st transfer section There is a positive contact between the transfer belt

application terminals and the high voltage unit

connection terminals (T1).

NO Clean or correct the terminal.

9 1st transfer section Scratches or dirt on 1st transfer roller. YES • Clean.

• Replace the transfer belt unit.

10 Developing section Toner bristles not even on the developing roller, resulting

in a line or band.

YES Replace the imaging unit.

NO Replace the PH unit.

4-color troubleshooting procedure

Step Section Check item Result Action

1 Paper path There is dirty or foreign matter on paper path. YES Check or clean the paper path

including the duplex section.

2 Transfer belt unit Lines that can be removed by cleaning are evident on

the transfer belt. (improper cleaning)

YES • Check or clean the cleaning

blade.

• Replace the transfer belt unit.

3 Transfer belt unit Dirt, scratches, or foreign matter on the transfer belt. YES • Clean.

• Replace the transfer belt unit.

4 Transfer belt unit There is a positive contact between the transfer belt

application terminals and the high voltage unit

connection terminals (T1).

NO Clean or correct the terminal.

5 2nd transfer section Dirt or foreign matter on the 2nd transfer roller. YES • Remove the foreign matter.

• Replace the transfer roller

unit.

6 2nd transfer section There is a positive contact between the application

terminals of the 2nd transfer and the connection

terminals (T2) and ground terminal of the high voltage

unit.

NO Clean or correct the terminal.

Loading...

Loading...