d-Color MF4003/MF3303

L TROUBLESHOOTING > 16. IMAGE QUALITY PROBLEM

L-141

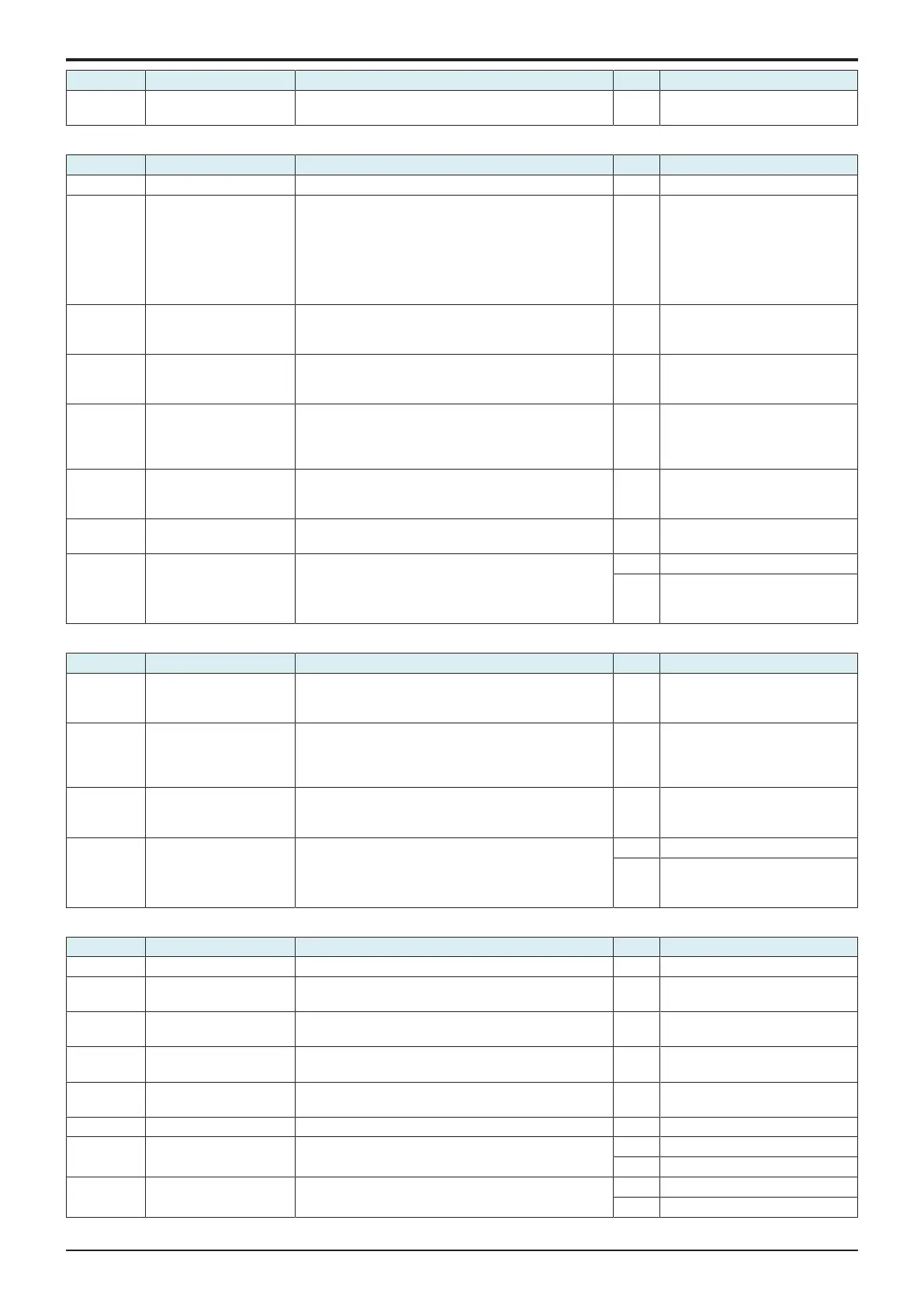

Step Section Check item Result Action

• Check the image after printing to determine which

color causes the abnormal image.

1-color troubleshooting procedure

Step Section Check item for the faulty color Result Action for the faulty color

1 Write section Dirt or foreign matter on the dust-proof glass of the PH. YES Clean the PH window.

2 Charging section Foreign matter on charging roller. YES Lightly wipe the surface clean of

foreign matter using hydro-wipe

(65AA-99##).

Note: Do not apply a strong force

to the surface of the charging

roller, as doing so can damage the

surface.

3 Photoconductor section There is a positive contact between the electrostatic

charger application terminals and the high voltage unit

connection terminals (Y: C4, M: C3, C: C2, K: C1).

NO Clean or correct the terminal.

4 Developing section There is a positive contact between the developing bias

application terminals and the high voltage unit

connection terminals (Y: B4; M: B3; C: B2; K: B1).

NO Clean or correct the terminal.

5 Service Mode -> TCR

data

Select [Service Mode] -> [State Confirmation] -> [Level

History 1] and the measured value is correct.

TCR-C, TCR-M, TCR-Y, TCR-K: normal value 5 to 8%

NO Select [Service Mode] -> [Imaging

Process Adjustment] -> [Manual

Toner Add] and perform the

function.

6 Service Mode -> Max

Image Density Adj

Select [Service Mode] -> [Imaging Process Adjustment] -

> [Max Image Density Adj] and make the necessary

adjustment, and the image trouble is eliminated.

NO Go to the next step.

7 Connector connection Faulty connector connection the high voltage unit (CN1)

and base board (CN4E).

YES Reconnect the connector.

8 Service Mode -> Initialize

+ Image Stabilization

Select [Service Mode] -> [Imaging Process Adjustment] -

> [Stabilizer] -> [Initialize + Image Stabilization] and

[Gradation Adjust], and the image trouble is eliminated.

YES Readjust.

NO • Replace the imaging unit.

• Replace the PH unit.

• Replace the high voltage unit.

4-color troubleshooting procedure

Step Section Check item Result Action

1 Transfer belt unit There is a positive contact between the transfer belt

application terminals and the high voltage unit

connection terminals (T1).

NO Clean or correct the terminal.

2 2nd transfer section There is a positive contact between the application

terminals of the 2nd transfer and the connection

terminals (T2) and ground terminal of the high voltage

unit.

NO Clean or correct the terminal.

3 Service Mode -> Max

Image Density Adj

Select [Service Mode] -> [Imaging Process Adjustment] -

> [Max Image Density Adj] and make the necessary

adjustment, and the image trouble is eliminated.

NO Go to the next step.

4 Service Mode -> Initialize

+ Image Stabilization

Select [Service Mode] -> [Imaging Process Adjustment] -

> [Stabilizer] -> [Initialize + Image Stabilization] and

[Gradation Adjust], and the image trouble is eliminated.

YES Readjust.

NO • Replace the transfer belt unit.

• Replace the high voltage unit.

• Replace the base board.

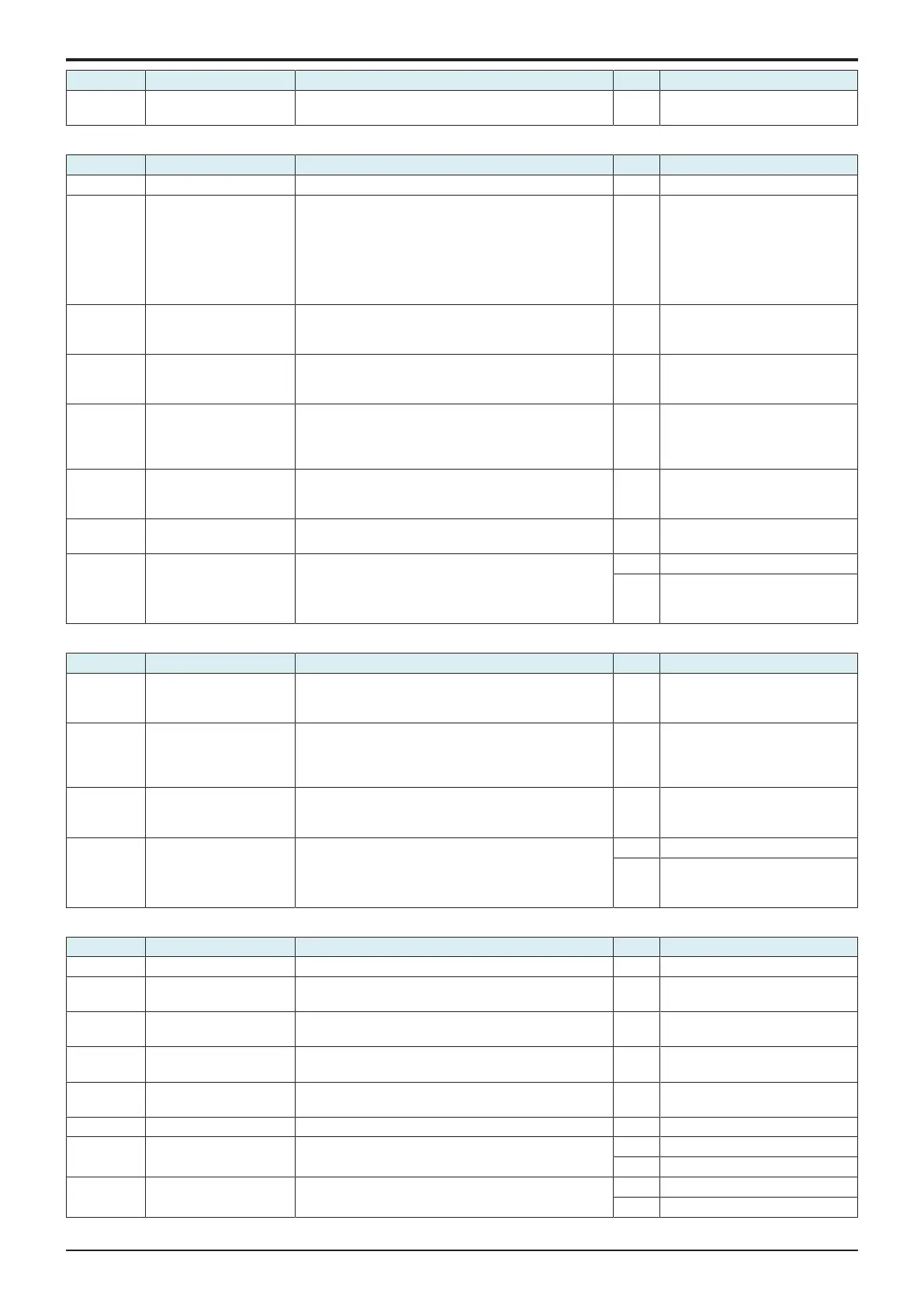

Scanner troubleshooting procedure

Step Section Check item Result Action

1 Original Original is damaged or dirty. YES Change the original.

2 Original Type Select [Copy] -> [Original Type] and change the setting,

and the image trouble is eliminated.

NO Go to the next step.

3 Basic -> Density Change the density setting, and the image trouble is

eliminated.

NO Go to the next step.

4 When DF is being used DF does not lie flat. YES Replace DF if it is deformed or

hinges are broken.

5 When original glass is

being used

Original glass or original pad is dirty. YES Clean.

6 Parts along scanning path Light guide or lens array is dirty. YES Clean.

7 When DF is being used:

1st side

Original reading glass is dirty. YES Clean.

NO Replace the CIS module.

8 When DF is being used:

2nd side

• Shading correction surface of DF is dirty.

• CIS glass is dirty.

YES Clean.

NO Replace the DF CIS module assy.

Loading...

Loading...