d-Color MF4003/MF3303

P THEORY OF OPERATION > 1. d-Color MF4003/MF3303

P-47

Mode 1 • When the main body has been in standby mode for 6 hours, the fusing roller is rotated for a

specified distance.

• When the main body has been in power save mode for 13 days, the fusing roller is rotated for a

specified distance. Afterwards, the main body returns to the power save mode.

Mode 2 • Disable

(3)Fusing temperature control

• The fusing temperature control detects the surface temperature of the fusing roller using the fusing temperature sensor and turns the

fusing heater lamp ON/OFF.

When the fusing heater lamp is turned ON, the fusing roller is heated at the specified temperature.

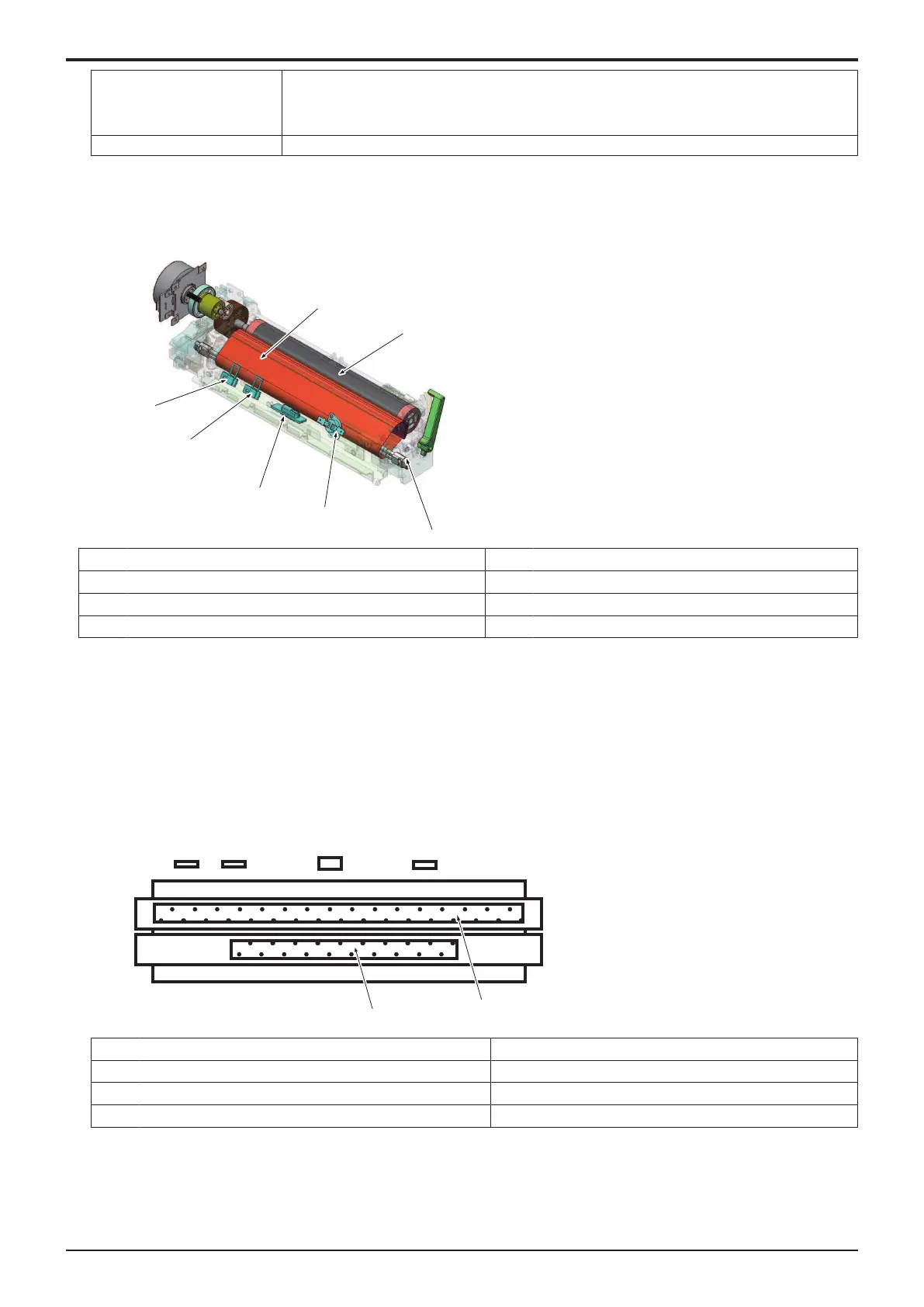

[1] Fusing belt [2] Pressure roller

[3] Fusing heater lamp (HL1) [4] Heating roller thermostat (TS1)

[5] Heating roller temperature sensor (TEMS) [6] Heating roller thermistor/Ctr (TH2)

[7] Heating roller thermistor/Edg (TH1) -

(a)Fusing heater lamp

• The heating roller contains a fusing heater lamp assy in it. The fusing heater lamp turns ON to generate heat, which heats the heating

roller and fusing belt.

• The fusing heater lamp assy consists of two heaters, each having a unique heating range different from each other.

• The fusing heater lamp/1 uniformly heats the entire area of the fusing roller.

• The fusing heater lamp/2 heats only the central portion of the fusing roller.

• The fusing heater lamp is turned ON or OFF according to the width of the paper and the surface temperature of the fusing belt.

• For a paper width of 148 mm or less, the fusing heater lamp/2 is used to heat the central portion.

• For a paper width exceeding 148 mm, the surface temperature of the fusing belt is measured and the fusing heater lamp/1 and

the fusing heater lamp/2 are alternately turned ON.

•

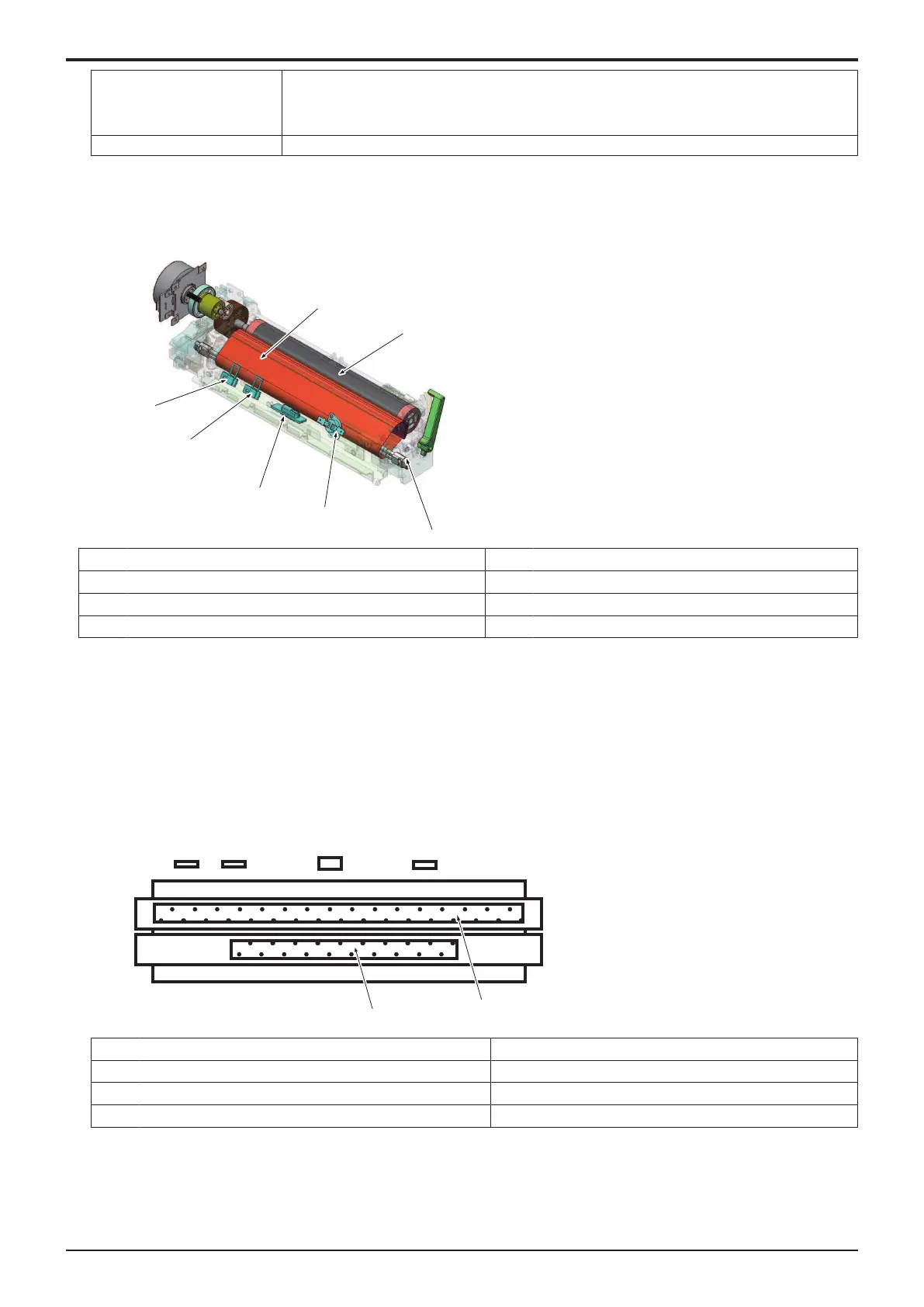

[1] Front of machine [2] Fusing heater lamp/1

[3] Fusing heater lamp/2 [4] Back of machine

[5] Heating roller thermistor/Edg (TH1) [6] Heating roller thermistor/Ctr (TH2)

[7] Heating roller temperature sensor (TEMS) [8] Heating roller thermostat (TS1)

Loading...

Loading...