09/03

2-271

DC 3535/2240/1632, WC M24

12-262

Status Indicator RAPs

Initial issue

12-262 Eject Clamp Home Sensor Off

The Eject Clamp Home Sensor does not turn off within 200ms after the Eject Clamp DOWN

has started.

Procedure

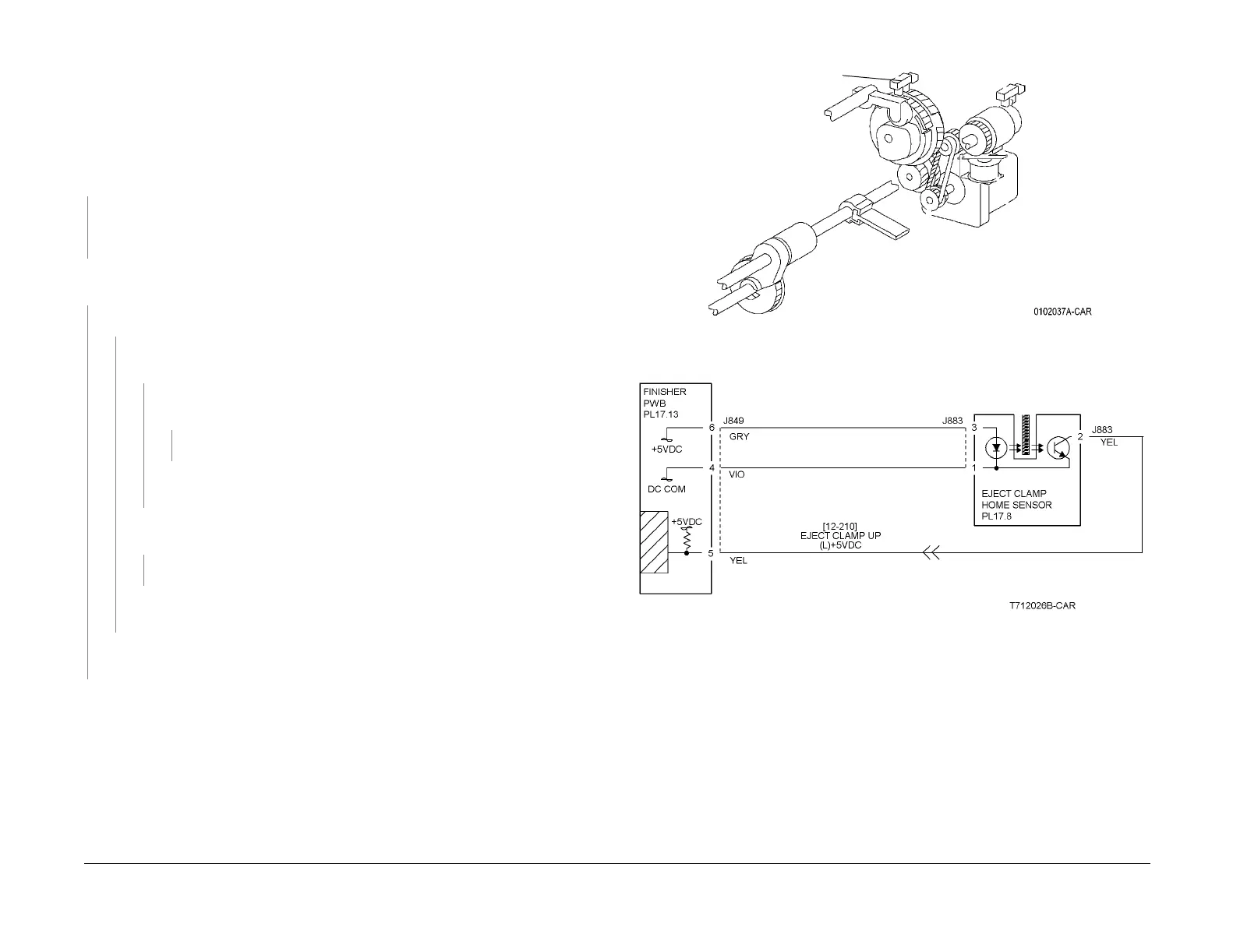

Remove the Rear Cover (PL 17.5) and the Eject Clamp Home Sensor bracket (PL 17.8) (leave

sensor connected). Enter dC330 [012-210] and press Start. Actuate the Eject Clamp Home

Sensor (PL 17.8) (Figure 1). The display changes.

YN

Press Stop. Check the Eject Clamp Home Sensor components for mechanical problems.

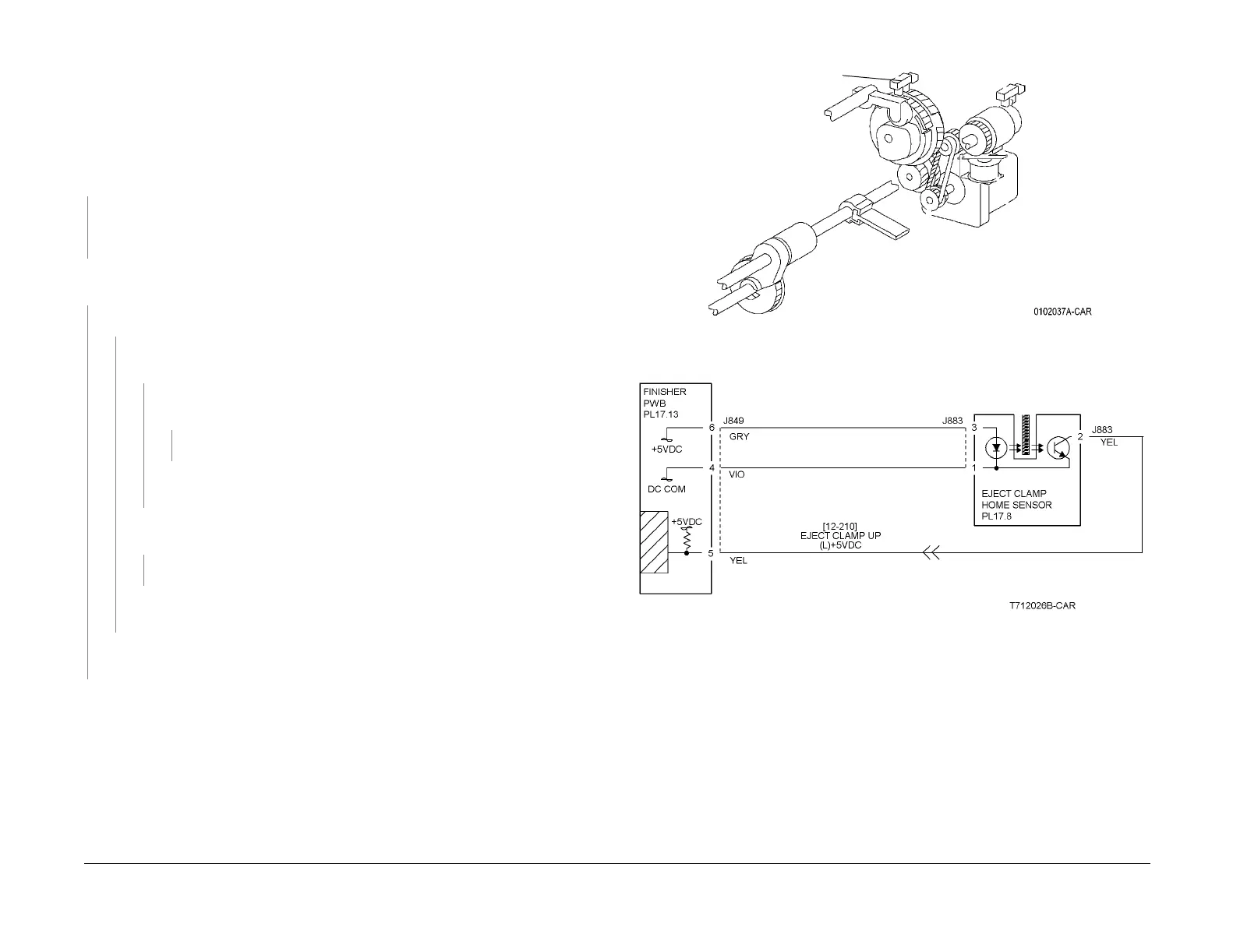

If the components are good, check the circuit of the Eject Clamp Home Sensor (Figure 2).

Refer to the OF 99-2 RAP for troubleshooting procedure

Press Stop. Restore mounting of the Eject Clamp Home Sensor. Enter dC330 [012-032] and

press Start. The Eject Clamp (PL 17.6) moves down.

YN

The Eject Motor (Figure 3) energized.

YN

Remove the Rear Cover (PL 17.5). +24 VDC is measured between P/J881- 2 and

5 on the Eject Motor and GND.

YN

+24 VDC is measured between P/J846- 6 and 12 on the Finisher PWB and

GND.

YN

Replace the Finisher PWB (PL 17.13).

Check wiring between P/J846- 6 and 12 and P/J881- 2 and 5 for damage or

poor contact.

+24 VDC is measured between P/J881- 1, 3, 4 and 6 on the Eject Motor and

GND.

YN

Replace the Eject Motor (PL 17.8).

Check the wires from P/J846 to P/J881 for an damage or poor contact. If the check

is OK, replace the Finisher PWB (PL 17.13).

Check the Eject Motor and its associated gears, pulleys and belts (PL 17.8) for damage,

contamination and misalignment.

Press Stop.

• Ensure that the connectors shown in the circuit diagrams (Figure 2, Figure 3) are securely

connected and that the wires are not damaged.

• Replace the Eject Clamp Home Sensor (PL 17.8).

• If the problem persists, replace the Finisher PWB (PL 17.13) (Figure 4).

Figure 1 Component Location

Figure 2 12-262 RAP Circuit Diagram - Eject Clamp Home Sensor

Eject Clamp Home Sensor

Loading...

Loading...