09/03

4-44

DC 3535/2240/1632, WC M24

REP 6.5

Initial issue

Repairs and Adjustments

REP 6.5 IIT/IPS PWB

Parts List on PL 18.3

Removal

1. Gather all available settings information. This includes the machine NVM log, the

Machine Settings floppy disk, copies of the Configuration Report, etc. If possible save the

current Machine Settings to the floppy.

WARNING

To avoid personal injury or shock, do not perform repair or adjustment activities with

the power switch on or electrical power applied to the machine.

CAUTION

PWBs can be damaged by electrostatic discharge. Observe all ESD procedures.

2. Remove the Platen Glass (REP 6.2).

3. Remove the IPS Cover (PL 18.3).

a. Manually move the Full Rate Carriage (PL 18.6) toward the left.

b. Remove front screws (2), left screws (2), and right screws (2) from IPS Cover (PL

18.3).

c. Loosen rear screw and remove cover.

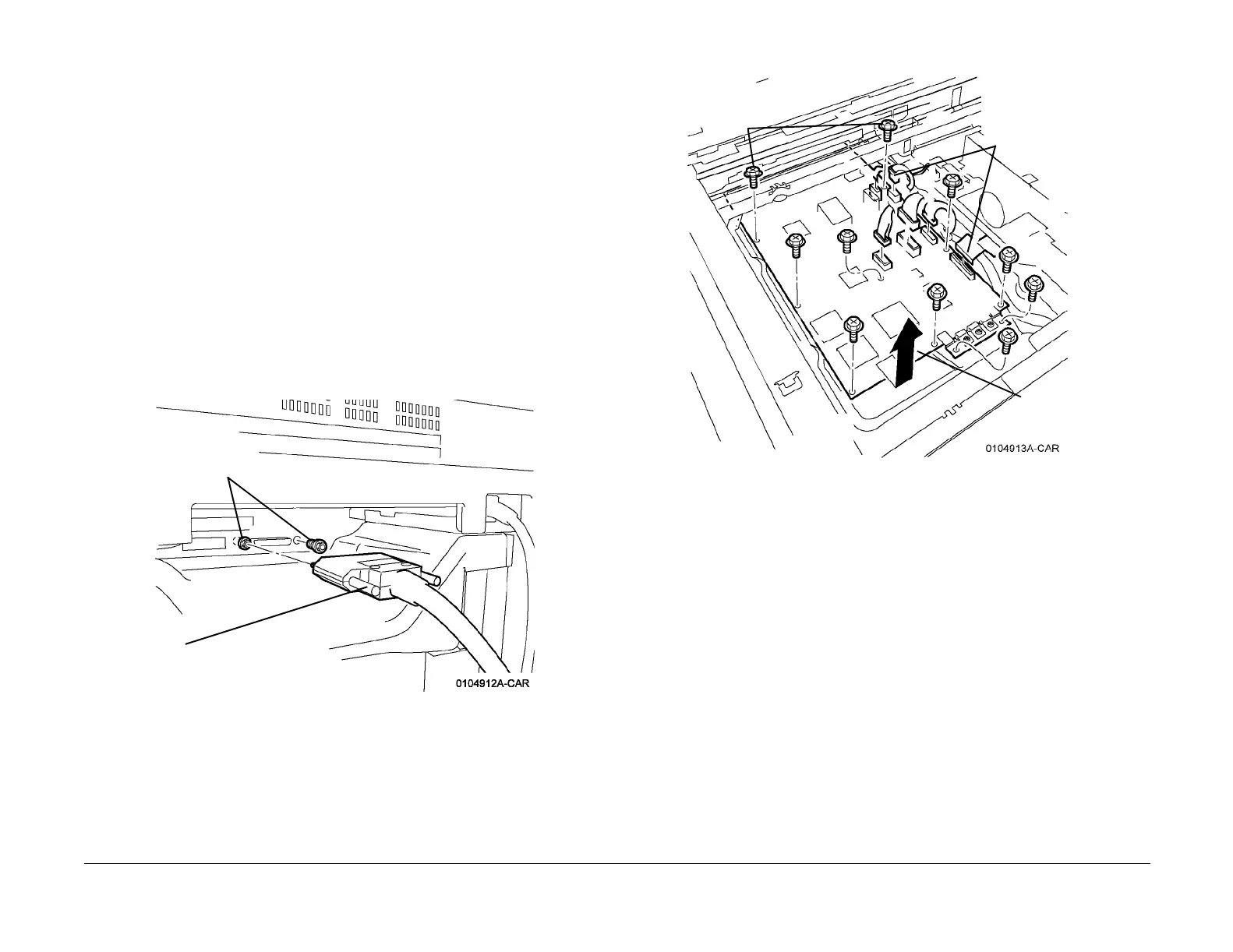

4. Disconnect IOT/IIT Cable and remove Screws from IIT (Figure 1).

Figure 1 Disconnecting Cable and Removing Screws from IIT

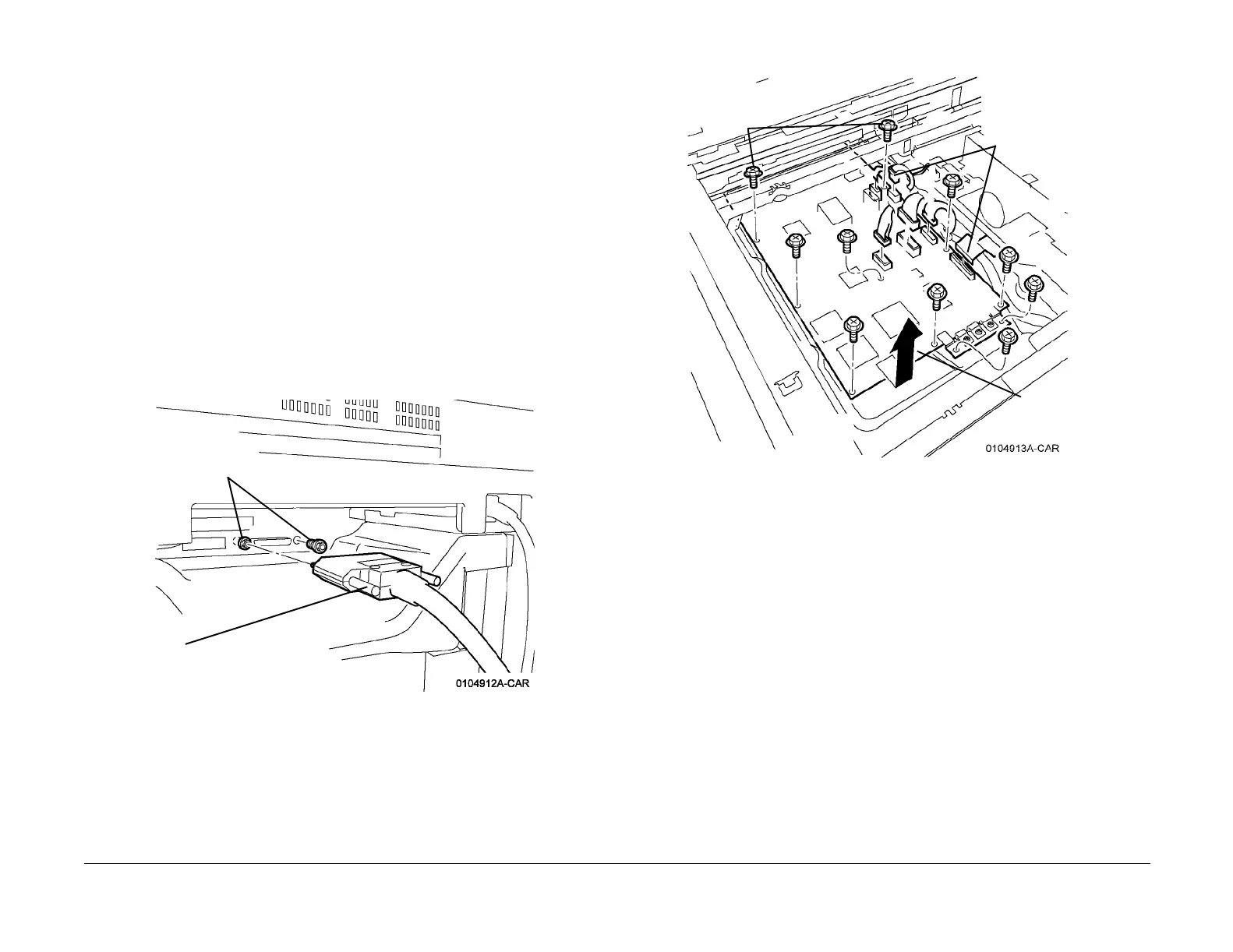

5. Remove IIT/IPS PWB (Figure 2).

Figure 2 Removing IIT/IPS PWB

Replacement

1. Install the new IIT/IPS PWB. Switch on the power and connect the PWS.

2. Check the IIT/IISS software version to ensure that it matches the system software config-

uration. Refer to the Software Configuration table in the system software upgrade instruc-

tions contained on the S/W update CD. If the version does not match, reload the software

in accordance with the instructions on the CD.

3. If a good Machine Settings floppy is available, exit, then reenter the PWS Tool. Select

Read from Floppy when starting the tool. If no floppy is available, or if the data on the

existing floppy is questionable, go to step 5.

4. Go to dC351 and select Restore Machine Settings. After completion, go to step 7.

5. If a good Machine Settings floppy is not available, or if the data on the existing floppy is

questionable, go to dC351. In the Special Batch Write area, select the appropriate market

region, then press the Batch Write NVM button.

6. Using the resources gathered in step 1 of the removal procedure, reenter NVM data to

restore the machine configuration.

7. Ensure that the customer settings are correct. Contact the customer’s system administra-

tor to configure, if necessary.

8. Perform the IIT Calibration (ADJ 9.7).

9. Go to dC351 and select Save Machine Settings. Save the settings to floppy disk per the

procedure.

1

Loosen Connector Screws

and Disconnect Plug

2

Remove

screw studs

(2)

1

Remove screws

(10)

2

Disconnect

connectors (6)

3

Remove

PWB

Loading...

Loading...