09/03

4-21

DC 3535/2240/1632, WC M24

REP 4.4

Repairs and Adjustments

Initial issue

REP 4.4 Drum Motor Assembly

Parts List on PL 1.1

Removal

WARNING

To avoid personal injury or shock, do not perform repair or adjustment activities with

the power switch on or electrical power applied to the machine.

CAUTION

Machine problems will result from careless harness routing during reassembly. Carefully

observe position of wiring harnesses for later reinstallation.

1. Remove the 24 VDC LVPS Chassis (REP 1.9).

2. Remove the Right Cover (REP 14.3).

3. Remove the Top Cover (REP 14.1).

4. Remove the Rear Cover (REP 14.2).

5. Remove the ESS DIMM cover (PL 13.1, item 4).

6. Disconnect J300 (DC2240/1632) or NJ300 (DC3535) from the ESS PWB.

CAUTION

Disengage locking tab on P/J400 before disconnecting.

CAUTION

PWBs can be damaged by electrostatic discharge. Observe all ESD procedures.

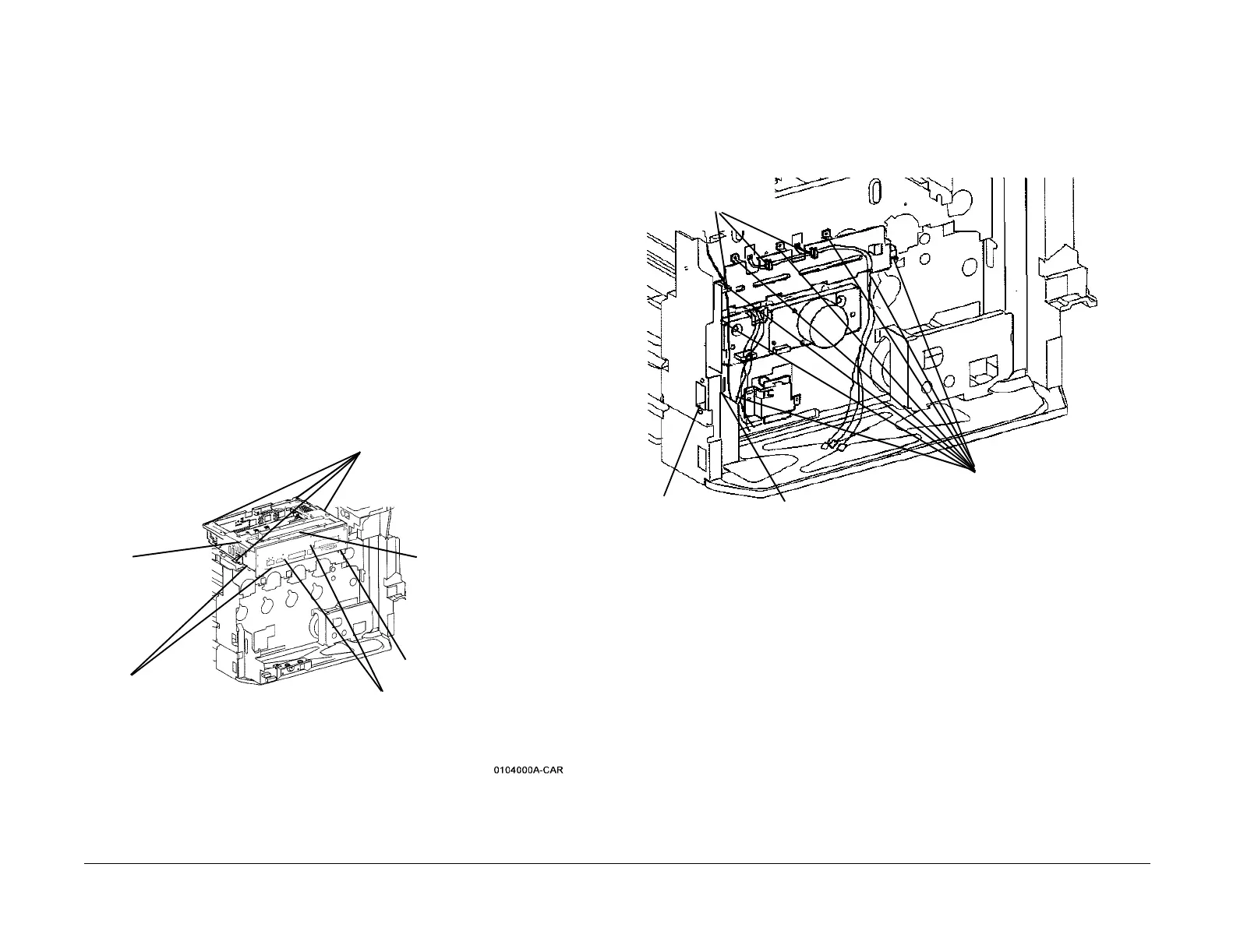

7. Remove the ESS Chassis Assembly (Figure 1).

Figure 1 Removing ESS Chassis

8. Remove the High Voltage Power Supply Chassis (REP 1.6).

NOTE: In next step, do not disconnect connectors.

9. Loosen the I/F PWB chassis mounting screws (2) and move chassis up (REP 1.8).

10. Remove the IBT Motor Assembly (REP 4.2).

11. Remove the BTR1 HVPS (REP 1.10).

12. Remove the LVPS Bracket (REP 1.1).

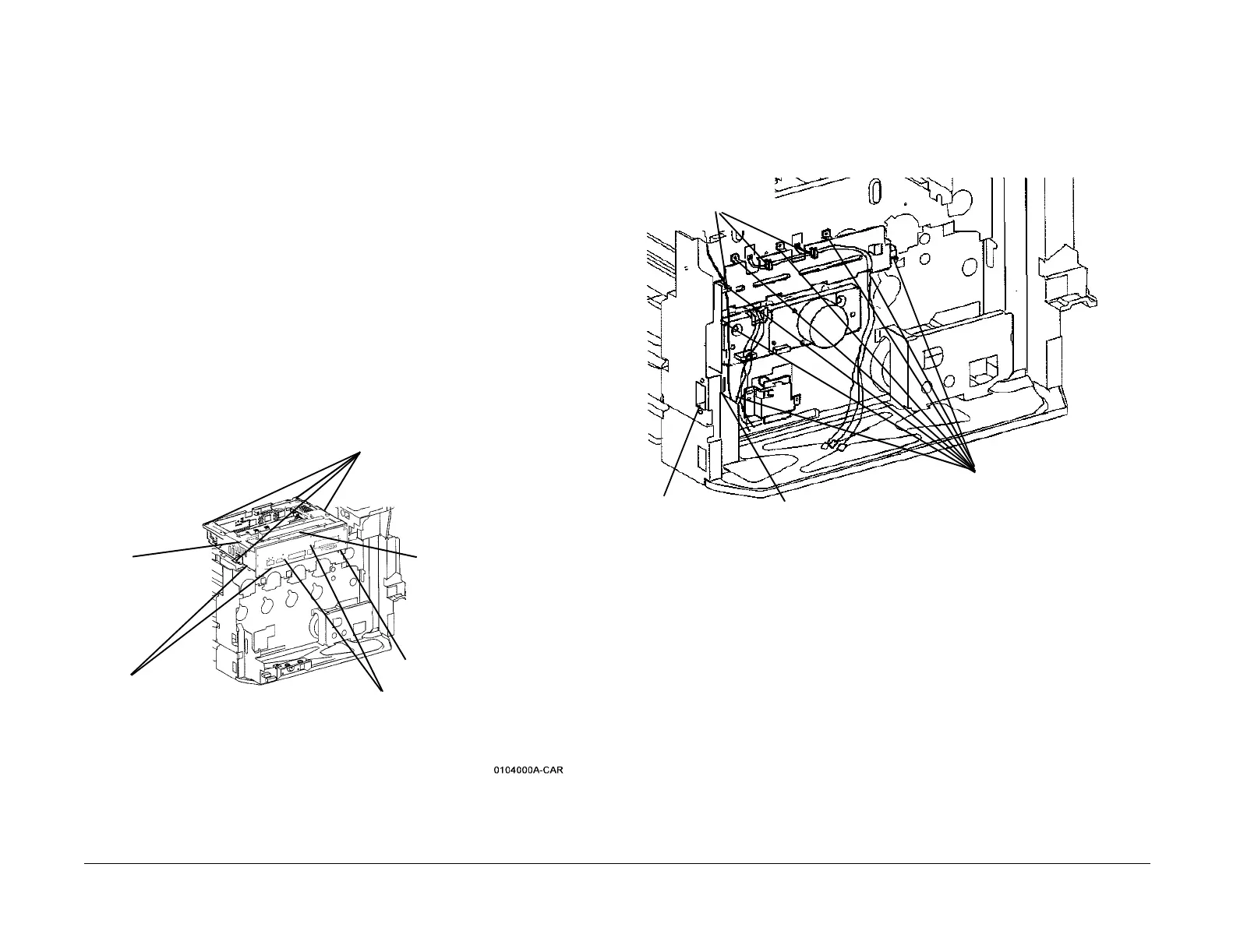

13. Remove the Drum Motor Assembly (Figure 2).

Figure 2 Removing Drum Motor Assembly

4

Remove screws (4)

1

Unlatch Harness Clips

(2)

3

Disconnect

Switch from

chassis

2

Disconnect connectors (8) from MCU PWB

(under chassis)

5

Lift outer end of chas-

sis to disconnect P/

J410 and remove

chassis

P/J400 (see CAUTION)

Release Harness Clips

2

Remove screws

(2)

3

Disconnect connector

4

Remove screws (8)

Loading...

Loading...