09/03

2-249

DC 3535/2240/1632, WC M24

12-170

Status Indicator RAPs

Initial issue

12-170 Set Eject

The Compiler Paper Sensor did not deactuate after the Eject Motor energized.

Initial Actions

• Check condition and specification of the paper supply.

• Check for obstructions in the paper feed path.

• Clean the Eject Roll and Eject Pinch Roll and check for wear.

Procedure

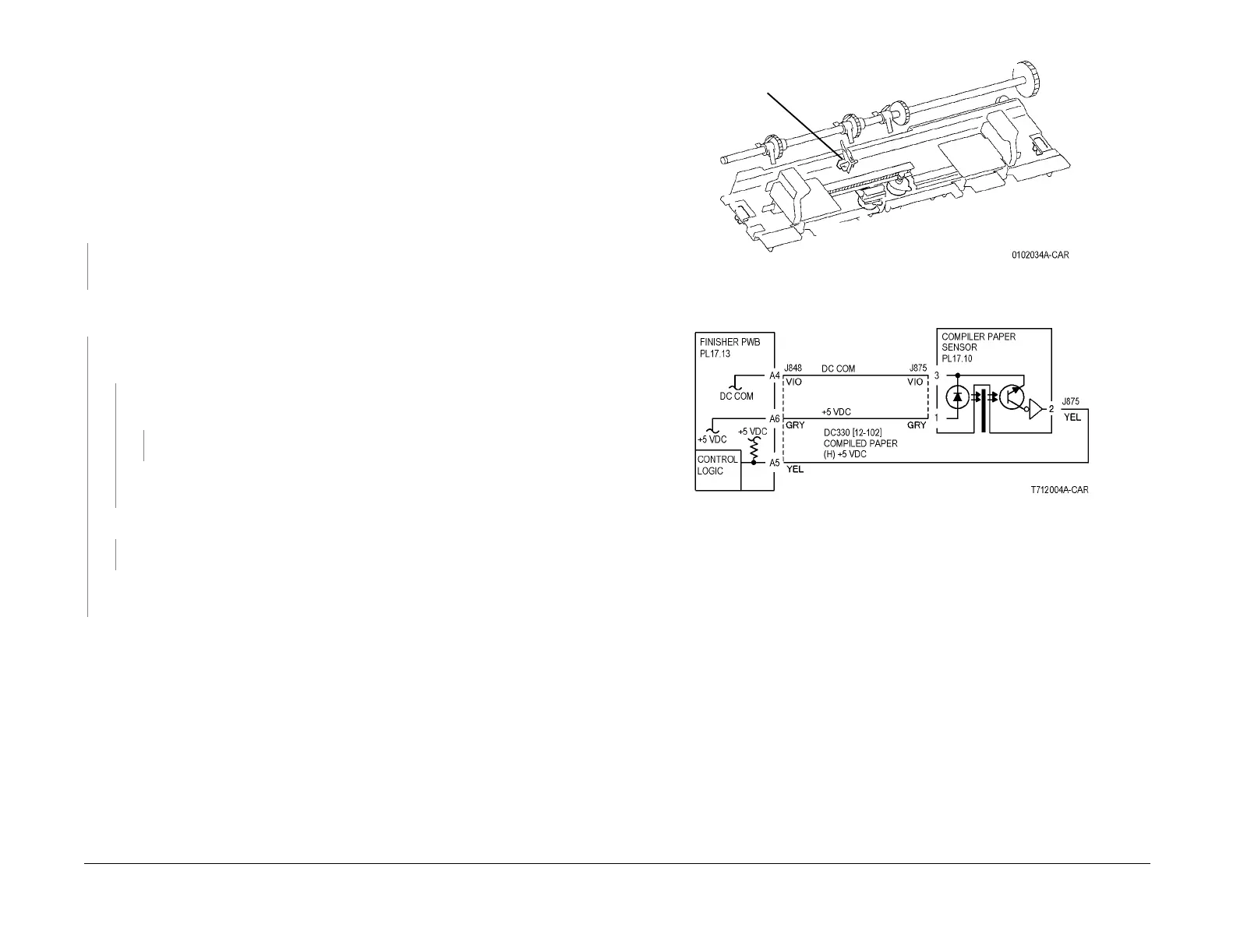

Enter dC330 [012-102] and press Start. Open the Top Cover (PL 17.6) and actuate the Com-

piler Paper Sensor (PL 17.10) (Figure 1). The display changes.

YN

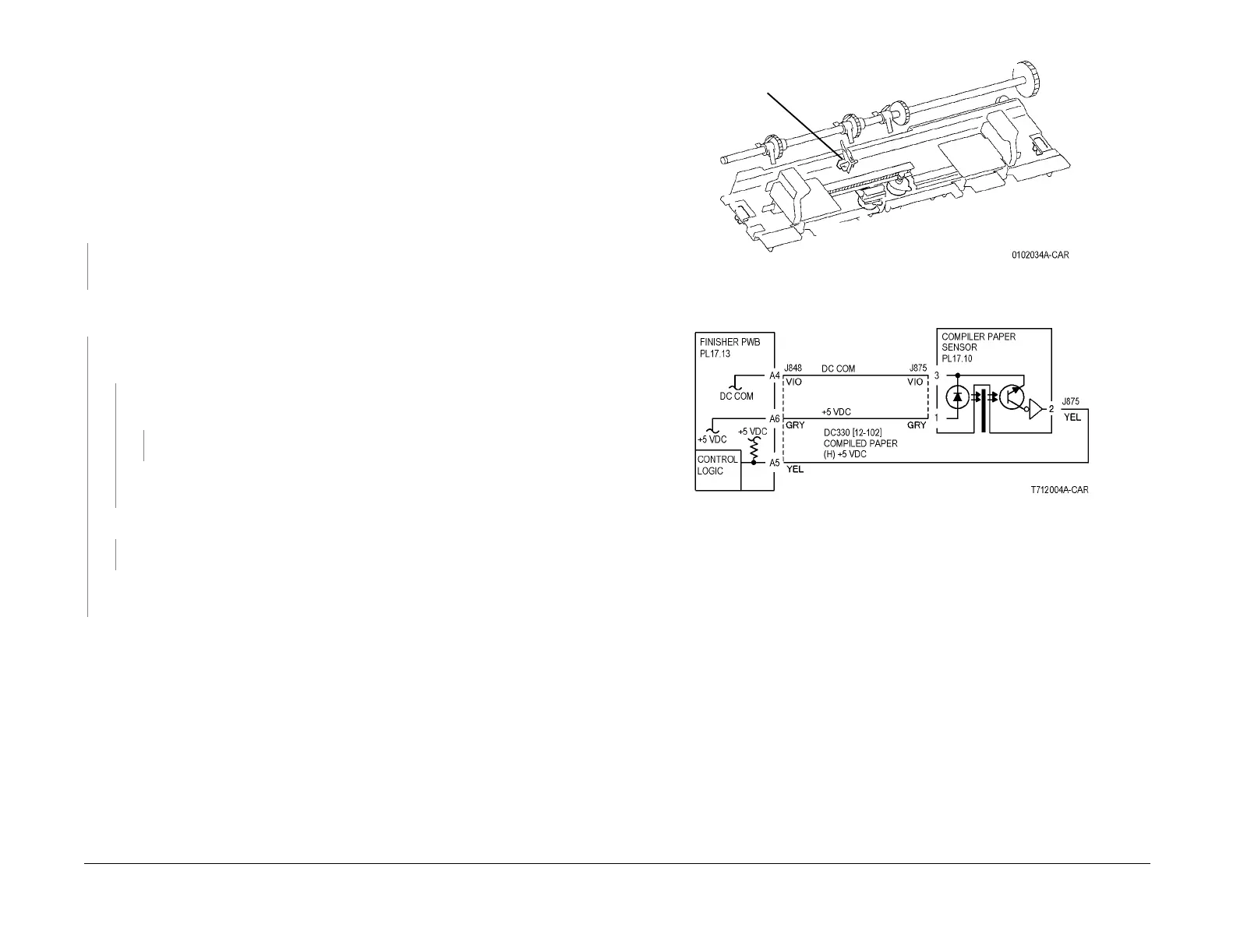

Press Stop. Check the circuit of the Compiler Paper Sensor (Figure 2). Refer to the OF

99-2 RAP for troubleshooting procedure.

Press Stop. Enter dC330 [012-030] and press Start. The Eject Motor (PL 17.8) energizes

Figure 3).

YN

Remove the Rear Cover (PL 17.5). +24 VDC is measured between P/J881 -2 and 5 on

the Eject Motor and GND.

YN

+24 VDC is measured between P/J846- 6 and 12 on the Finisher PWB and

GND.

YN

Replace the Finisher PWB (PL 17.13).

Check wiring between P/J846- 6 and 12 and P/J881- 2 and 5 for damage or poor

contact.

+24 VDC is measured between P/J881- 1, 3, 4 and 6 on the Eject Motor and GND.

YN

Replace the Eject Motor (PL 17.8).

Check the wires from P/J846 to P/J881 for damage or poor contact. If the check is OK,

replace the Finisher PWB (PL 17.13).

Check the following:

• Ensure that the connectors shown in the circuit diagrams (Figure 2, Figure 3) are securely

connected and that the wires are not damaged.

• Check the Eject Motor and its associated gears, pulleys and belts (PL 17.8) for damage,

contamination or misalignment.

• Eject Clamp for an up and down movement failure (PL 17.8).

• Stacker Tray for foreign substance (PL 17.1).

• Replace the Compiler Paper Sensor (PL 17.10).

• If the problem persists, replace the Finisher PWB (PL 17.13) (Figure 4).

Figure 1 Component Location

Figure 2 12-170 RAP Circuit Diagram - Compiler Paper Sensor

Compiler

Paper

Sensor

Loading...

Loading...