09/03

6-109

DC 3535/2240/1632, WC M24

dC330

General Procedures and Information

Initial issue

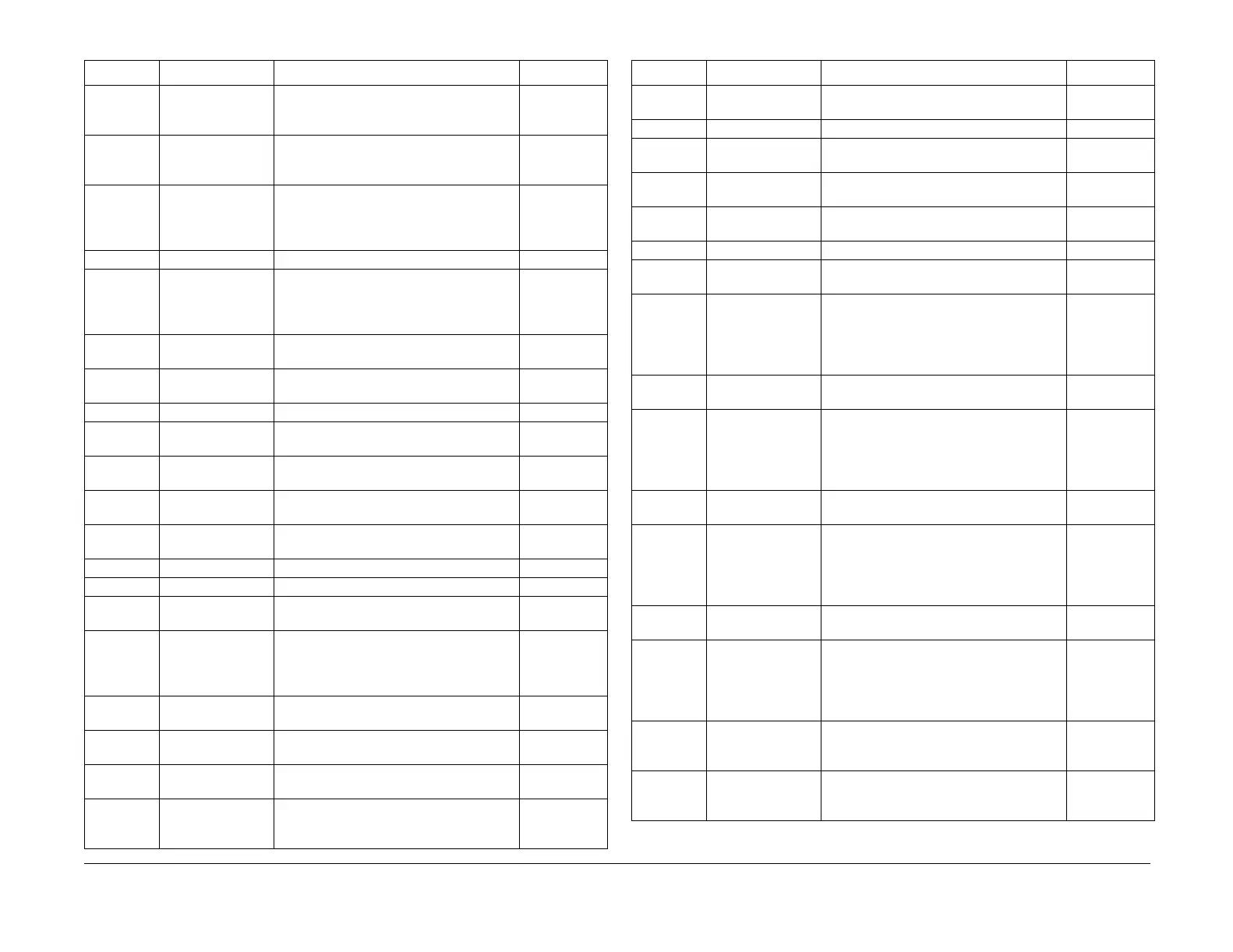

004-011 Drum Motor YMC

(52mm/sec.)

Rotate at low speed. Remove all Drum Car-

tridges before energizing to prevent Belt

damage.

004-003

004-012 IBT Motor (52mm/

sec.)

Rotate at low speed. Operate with the IBT

Assy. removed to prevent Transfer Belt

damage.

004-002,

004-013

004-013 IBT Motor (high

speed)

Rotate at high speed. Operate with the IBT

unit removed. The Belt might be damaged

since the Belt Work Control is not per-

formed.

004-002,

004-012

004-014 IBT_5V ON ON = High. -

004-050 Fuser Fan, LV Fan

and Rear Fan

Rotation High

speed

Rotate the FUSER FAN, LV FAN and

REAR FAN at high speed. (Rotation is Low

at Power ON)

-

005-011 Set Gate Solenoid

Open

Turn Set Gate Open ON (Towards bottom

of Nudger Roll) for 5sec -> Auto OFF

-

005-012 Set Gate Solenoid

Close

Turn Set Gate Close ON (Towards bottom

of Nudger Roll) for 5sec -> Auto OFF

-

005-040 Feed Mot. DADF Feed Motor for 2sec -> Auto OFF -

005-055 Belt Motor Non

CVT Mode (CW)

Rotate the DADF Belt Motor forward. 005-056

005-056 Belt Motor Non

CVT Mode (CCW)

Rotate the DADF Belt Motor backward. 005-055

005-075 Regi Gate Solenoid Push the Regi Gate with the Arm to turn it

ON for 5sec -> Auto OFF

-

005-081 Exit Motor Non

CVT Mode

Operate the DADF Exit Motor -

005-083 Doc Ready switch ON the Doc Ready signal. -

005-084 Doc Set LED switch ON the DOC SET LED -

006-002 IIT Exposure Lamp switch the Lamp ON for 180sec -> Auto

OFF

-

006-004 IPS Cooling Fan

(Low speed)

After operating the IPS Cooling Fan at high

speed for 5sec, operate it at low speed. ON

= FAN. ON = 24V, FAN Slow: L->H (About

13V)

-

006-005 IIT Scan Motor

(Scan)

More it 50mm from current position in Scan

direction -> Auto OFF

006-006

006-006 IIT Scan Motor

(Return)

More it 50mm from current position in

Return direction -> Auto OFF

006-005

006-014 IPS Cooling Fan

(High speed)

Operate the IPS Cooling Fan at high

speed.

-

006-030 LD ON Enable Sig-

nal (concurrently

for 4 colors)

-

Table 2 Output Component Control Codes

Code Name Description Conflicts

006-031 Polygon Motor

Start Signal

-

006-032 SOS Gain Start-of-Scan Sensor gain signal

006-086 IIT Image Area IMG-AREA Signal Output. ON = P727

LVDS (Differential) High

-

006-091 Exchange To ADF Turn ON the document exchange com-

mand signal to the DADF

-

007-003 Tray 5 FEED

Clutch

-

007-004 HOTLINE_TRAY Not used. -

008-001 #1Feed Motor

(Fwd)

Feed (Rotate #1Feed Motor in paper feed

direction at 200mm/sec.)

8-002

008-002 #1Feed Motor

(Rev)

It switches OFF automatically 6sec after

LiftUp has started, or when the Level Snr

detected LiftUp. LiftUp cannot be per-

formed when the Level Snr should detect

LiftUp.

8-001

008-003 #2Feed Motor

(Fwd)

Feed (Turn #2Feed Motor On in paper feed

direction at 192mm/sec.)

8-004

008-004 #2Feed Motor

(Rev)

It switches OFF automatically 6sec after

LiftUp has started, or when the Level Snr

detected LiftUp. LiftUp cannot be per-

formed when the Level Snr should detect

LiftUp.

8-003

008-005 #3Feed Motor

(Fwd)

Feed (Turn #3Feed Motor On in paper feed

direction at 192mm/sec.)

008-006 #3Feed Motor

(Rev)

It switches OFF automatically 6sec after

LiftUp has started, or when the Level Snr

detected LiftUp. LiftUp cannot be per-

formed when the Level Snr should detect

LiftUp.

8-005

008-007 #4Feed Motor

(Fwd)

Feed (Turn #4Feed Motor On in paper feed

direction at 192mm/sec.)

8-008

008-008 #4Feed Motor

(Rev)

It switches OFF automatically 6sec after

LiftUp has started, or when the Level Snr

detected LiftUp. LiftUp cannot be per-

formed when the Level Snr should detect

LiftUp.

8-007

008-009 Dup Motor

(200.1mm/sec.)

Start operation. Switches OFF automati-

cally at 1000msec.

8-010, 011,

012, 053, 054,

055, 056

008-010 Dup Motor

(104mm/sec.)

Start operation. Switches OFF automati-

cally at 1000msec.

8-009, 011,

012, 053, 054,

055, 056

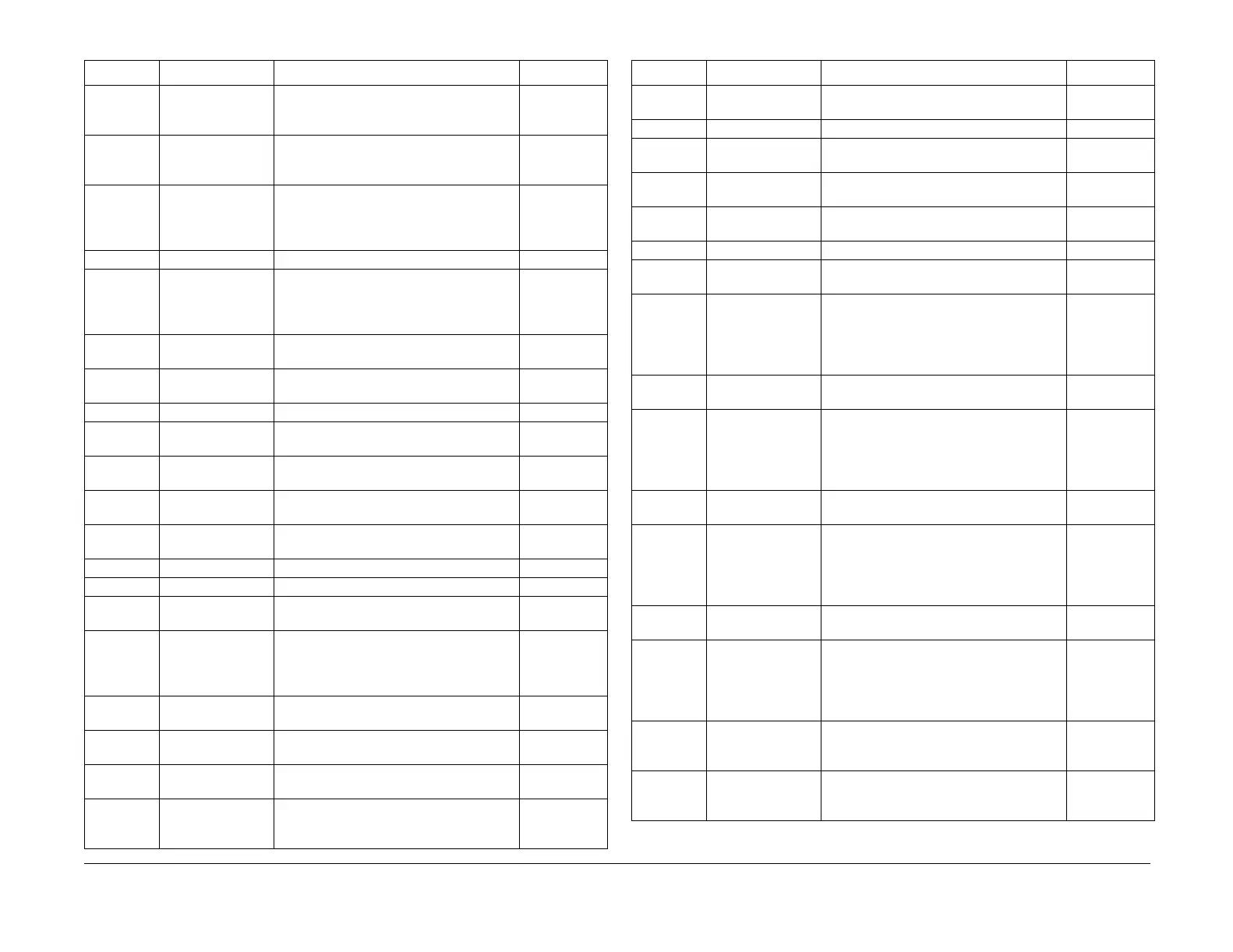

Table 2 Output Component Control Codes

Code Name Description Conflicts

Loading...

Loading...