Process Control

D014/D015/D078/D079 6-36 SM

One ID sensor above the image transfer belt reads the K, M, C, and Y patterns on the belt.

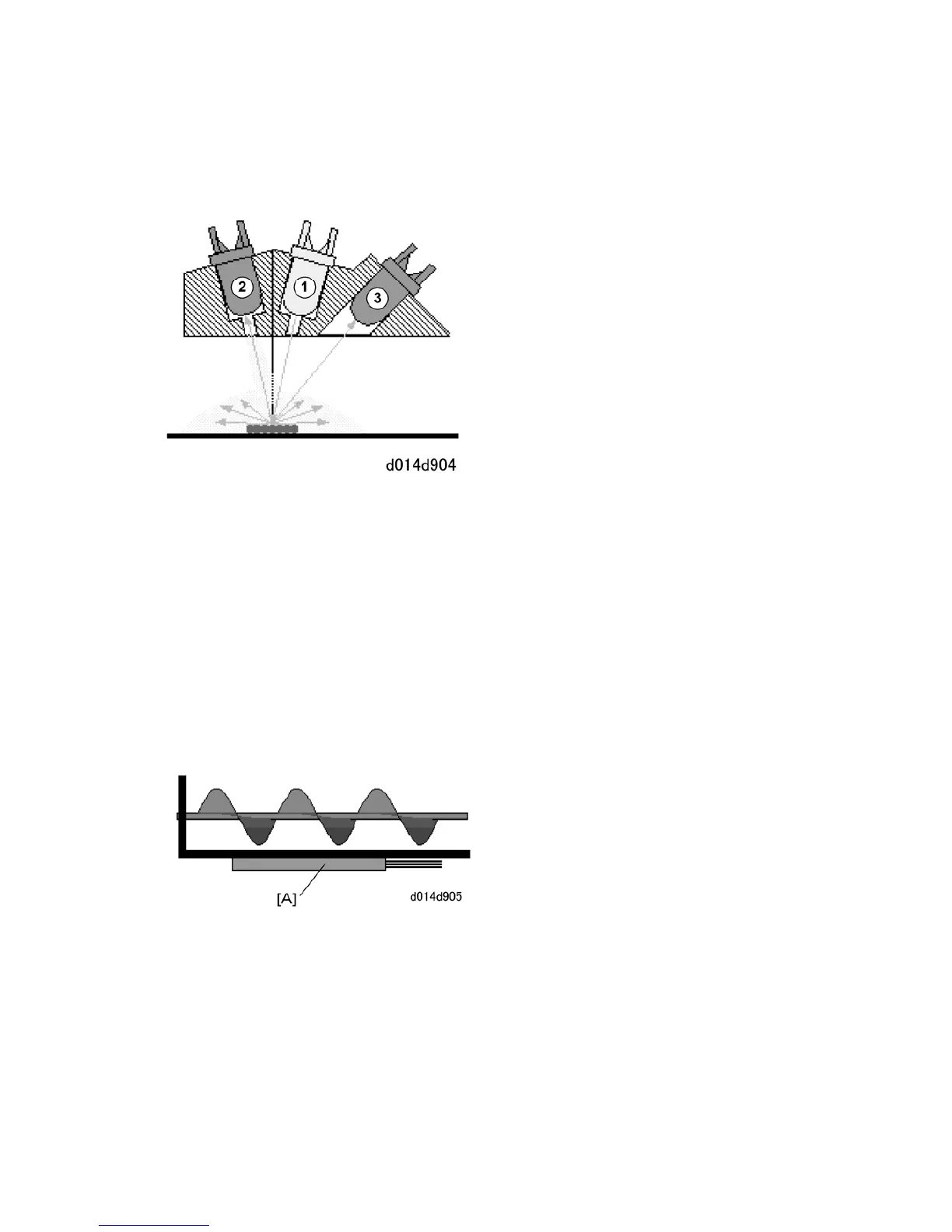

Three diodes comprise the ID sensor:

(1) Emitter. Emits light on the patterns.

(2) Direct reflector sensor. Gathers light reflected directly from the patterns.

(3) Diffused reflector. Gathers diffuse light from the sides of the patterns to achieve

more accurate readings especially for Y, M, C.

During process control, the creation of the patterns is timed so the Magenta, Cyan and

Yellow patterns are transferred to the ITB at approximately the same time. The ID sensor

reads the patterns in the order K, M, C, Y.

TD Sensor

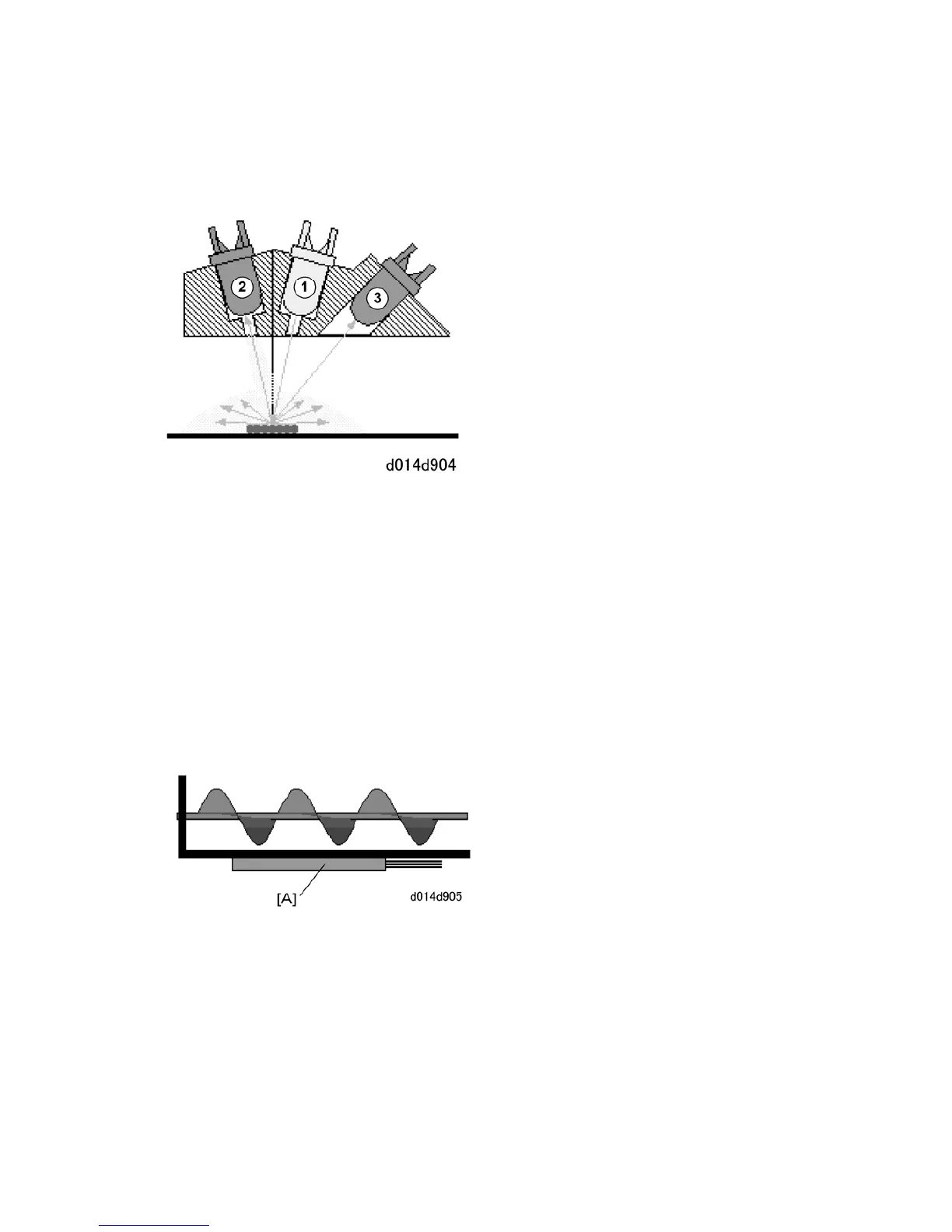

A TD sensor [A] is attached to the bottom of the development unit in each PCU.

The TD sensor directly measures the amount of toner in the developer/toner mixture.

Unlike previous machines, this TD sensor is not in direct contact with the developer/toner

mixture.

Vt is the output voltage of the TD sensor. When Vt goes high, toner is added to the

developer to bring Vt back to the Vtref value.

Loading...

Loading...