EPSON AcuLaser CX11/CX11F Revision B

TROUBLESHOOTING Printer 186

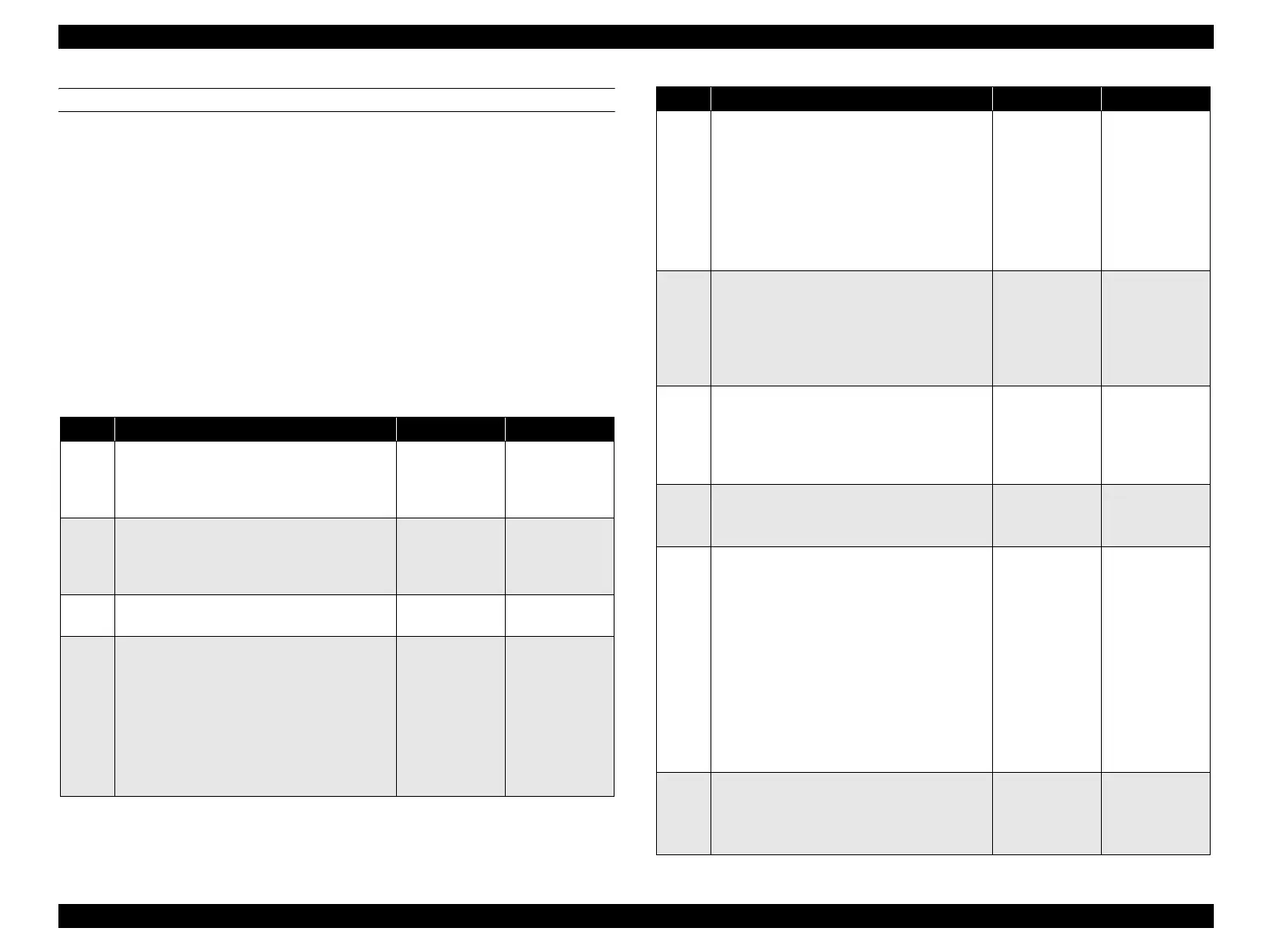

FIP-29

Panel Message

Jam E

Possible parts that caused the error

Troubleshooting

ROLL ASSY PRE-REGI ROLL-PINCH

ROLL-REGI METAL ROLL REGI RUBBER

ACTUATOR-REGI SENSOR REGI

MOTOR-PH HARNESS-ASSY P/H1

HARNESS-ASSY P/H2 PWBA MCU

LV/HVPS HARNESS ASSY MAIN

Step Check Yes No

1

Paper size check

Is the paper size compliant with the

specifications?

Go to Step[2]. Use paper of size

compliant with

the

specifications.

2

Paper size setting check

Does the size of the paper in use match the size

of the paper set on the control panel?

Go to Step[4]. Change the paper

size setting, and

proceed to step

[3].

3

Does the error recur when a test print is

made by dialog operations?

Go to Step[4]. End of procedure

4

Shape and operation check of ROLL ASSY

PRE-REGI and ROLL-PINCH

Open CHUTE ASSY-REAR.

Are ROLL ASSY PRE-REGI and ROLL-

PINCH attached correctly?

Also, do these parts rotate smoothly without

any dirt or damage?

Turn by hand to check.

Go to Step[5]. Replace or re-

attach ROLL in

question.

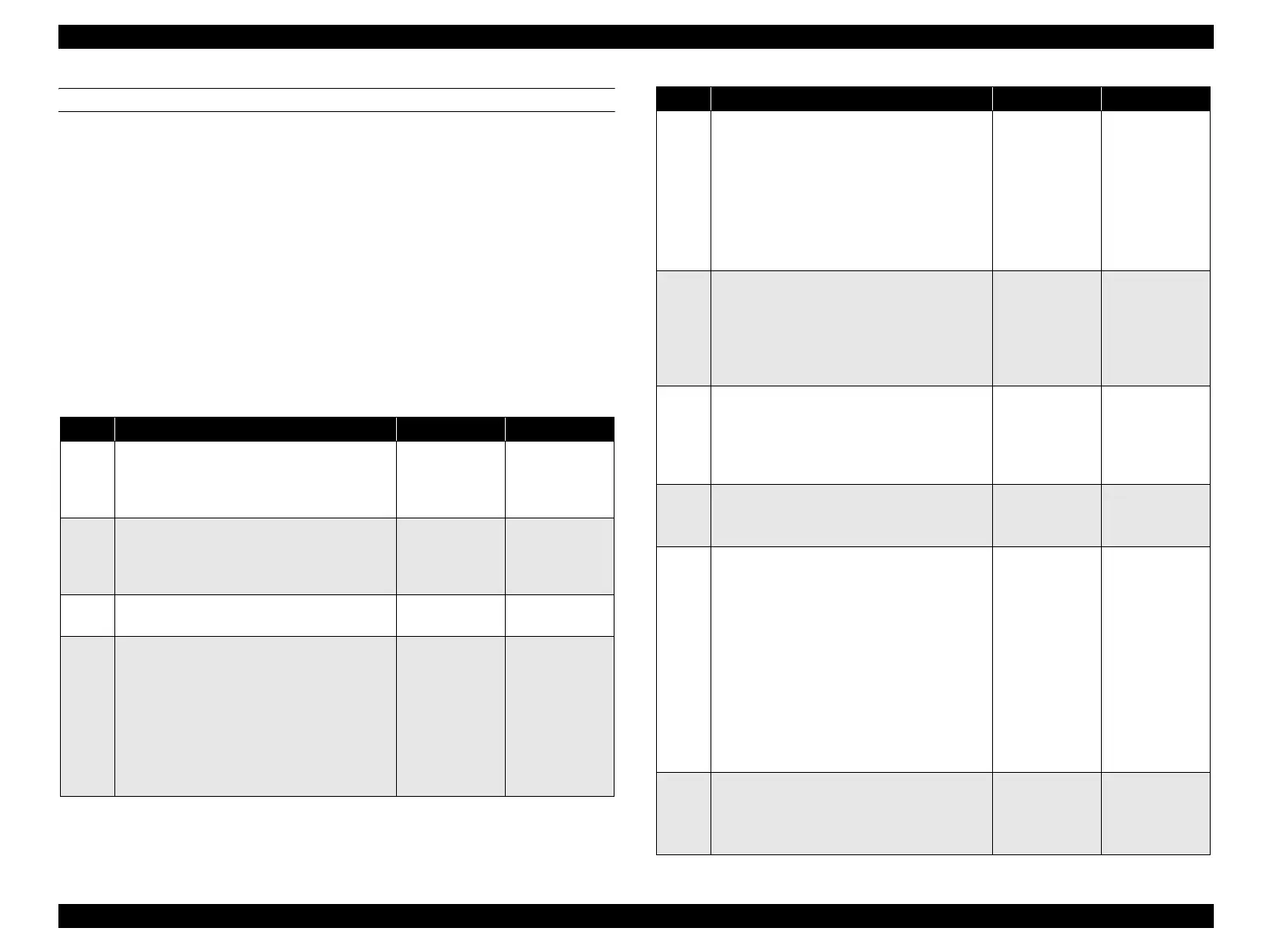

5

Shape and operation check of ROLL-REGI

METAL and ROLL REGI RUBBER

Open CHUTE ASSY-REAR.

Are the ROLL-REGI and ROLL REGI

RUBBER attached correctly?

Also, do these parts rotate smoothly without

any dirt or damage?

Turn by hand to check.

Go to Step[6]. Replace or re-

attach ROLL in

question.

6

Operation check of ACTUATOR-REGI

Does ACTUATOR-REGI move smoothly

without any damage? Does ACTUATOR-

REGI enter the sensor sensing area when there

is paper? Does it leave the sensor sensing area

when there is no paper?

Go to Step[7]. Replace

ACTUATOR-

REGI. (p.360)

7

Operation check of SENSOR REGI

The voltage of P408-12 ↔ P408-11 on PWBA

MCU is 0 VDC when ACTUATOR REGI

enters the sensing area of SENSOR REGI, and

is 5 VDC when it leaves the sensing area?

Go to Step[8]. Go to Step[11].

8

24 VDC power supply check to MOTOR-PH

The voltage of P409-6 ↔ P409-5 on PWBA

MCU is 24 VDC?

Go to Step[9]. Go to Step[14].

9

Continuity check of HARNESS-ASSY P/H1

Disconnect P/J405 and P/J604 from PWBA

MCU.

Do all of the wiring below have normal

continuity?

J409-1 ↔ P604-6

J409-2 ↔ P604-5

J409-3 ↔ P604-4

J409-4 ↔ P604-3

J409-5 ↔ P604-2

J409-6 ↔ P604-1

Go to Step[10]. Replace

HARNESS-

ASSY P/H1.

10

Check after replacement of MOTOR-PH

Replace MOTOR-PH. (p.362)

Does the error recur when the power is turned

ON?

Replace PWBA

MCU. (p.432)

End of procedure

Step Check Yes No

manuals4you.commanuals4you.com

Loading...

Loading...