According to the toner density measured by this sensor, the proper amount of toner is supplied to the

developer.

A counter corresponding to the frequency is used as the unit of TD sensor output. Thus, unlike a HST

sensor which directly detects Vt, the TD sensor output is converted into Vt for toner supply control.

In the TD sensor, there is an ID chip storing the machine identification information, the running distance

information of development unit and PCU, and other information used by image density control.

Process Control

Outline

Process control adjusts the condition of the imaging hardware to maintain a constant image density.

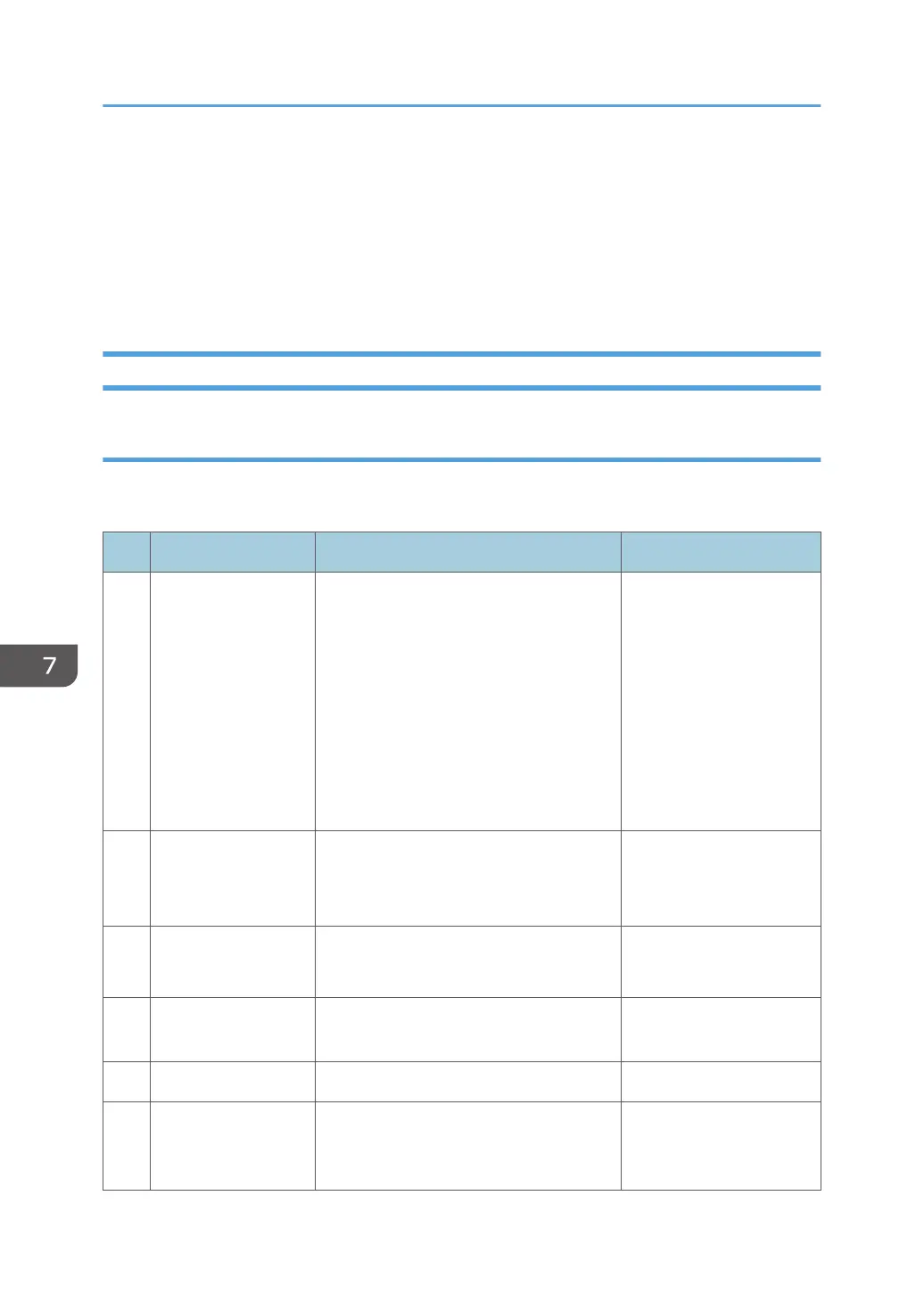

Process control is executed at the following times.

Process Control Operative Condition Related SPs

1

PowerON

ProCon :Set

When a certain time has passed after the

previous job end

(Except when recovering from an SC or

jam)

SP3-530-001

SP3-530-002

SP3-530-003

SP3-530-004

SP3-530-005

SP3-530-006

SP3-530-007

SP3-530-008

2 JobEnd ProCon :Set

When the value of the job end counter

becomes more than the threshold

(At job end)

SP3-534-001 to 004

SP3-534-011 to 014

3 Interrupt ProCon :Set

When the value of the job interrupt

counter becomes more than the threshold

SP3-533-001 to 004

SP3-533-011 to 014

4

Non-useTime

Procon :Set

When the value of the non-use time

counter becomes more than the threshold

SP3-531-001 to 004

5 Manual ProCon :Exe When SP 3-011 is used SP3-011-001 to 005

6 Toner End Recovery

After the Toner End Status is cleared

(Recovery is NOT done in the near end

status)

-

7. Detailed Descriptions

1120

Loading...

Loading...