Diagnostic aids 3-59

5058-030

of the paper. The toner image is now on the paper and the paper is now stuck to the transfer belt due to the

relative electrical differences.

Service tips

• If the transfer roller has nicks, pits, or flat spots on it, the surface doesn’t come into contact

with the media and transfer unit properly. This will cause voids or light spots on the page or

repeating voids/light areas, because the toner can’t be fully transferred due to the charge

difference in the areas of damage.

• If the transfer roller does not engage the transfer unit, or does not have voltage coming from

the high-voltage power supply, the toner will not fully transfer from the transfer unit. As a

result, the entire page will be very light or blank. Any toner that does transfer will be due to a

contact transfer instead of a charge transfer. Check the high-voltage power supply contacts to

the transfer roller.

Step 7: Electric Discharge

A detack saw evenly neutralizes the charge on the paper in order to separate the paper from the belt.

Step 8: Cleaning (Transfer belt/2nd transfer roll)

Some of the unwanted toner will remain on the 2nd transfer roll. To remove these, a positive voltage from the

HVPS is applied to transfer the unwanted toner to the transfer belt.

A cleaning blade comes into contact with the transfer belt and scrapes off the remaining toner on the belt

surface. The scraped toner is then transported to the waste toner cartridge.

Step 9: Fusing

The paper with the toner image has to go through fusing in order to bond the toner particles to the paper surface.

The paper passes to a heat belt, which is heated by the inner heater to melt the toner particles on the paper

surface. At the same time, pressure is also applied to permanently fuse the toner onto the media. The fuser then

moves the printed media to the redrive rolls, which transport the media to the output bin.

The fuser is equipped with a pressure roll retract mechanism that retracts the fuser pressure roll from the fuser

heat belt when printing is not taking place or when the fuser is removed from the machine. This feature reduces

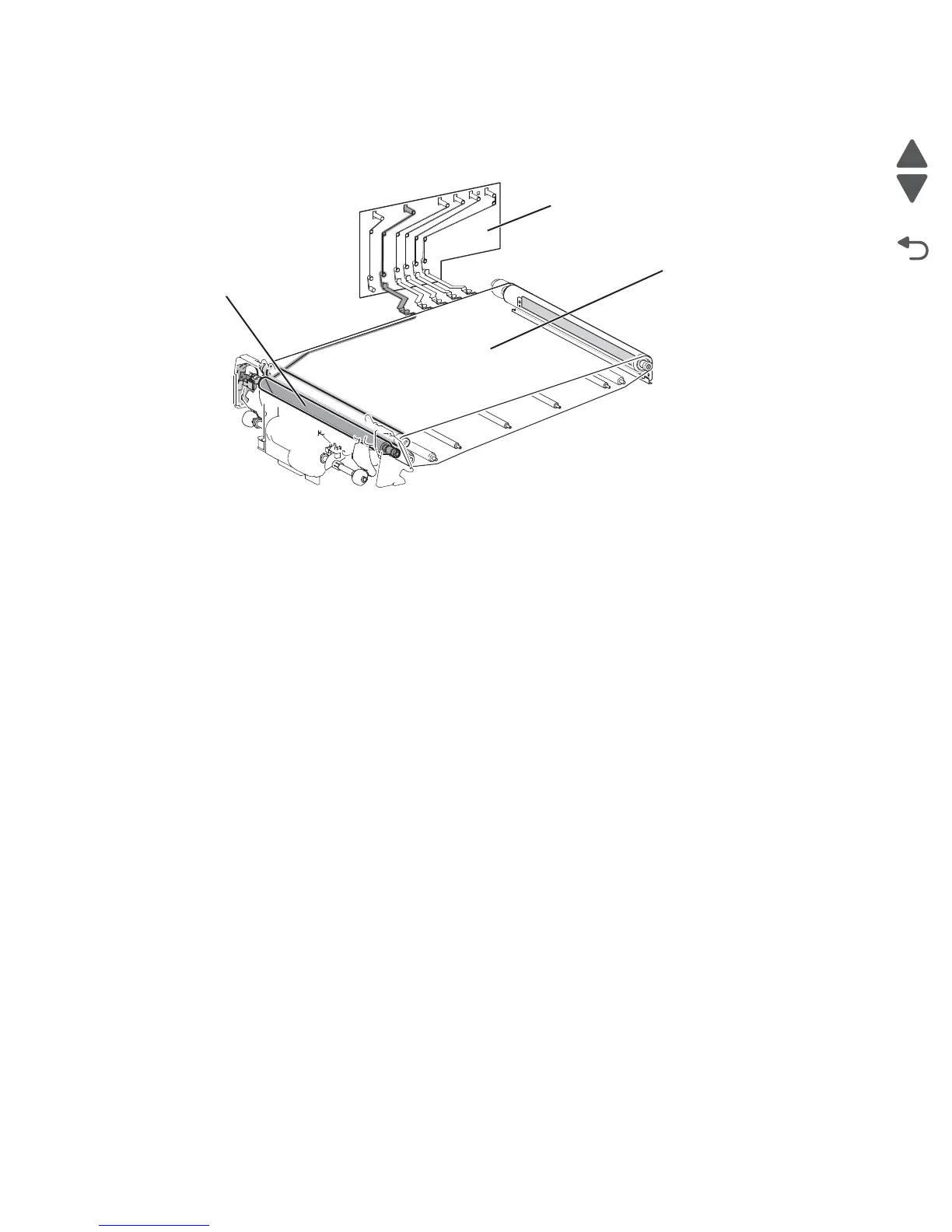

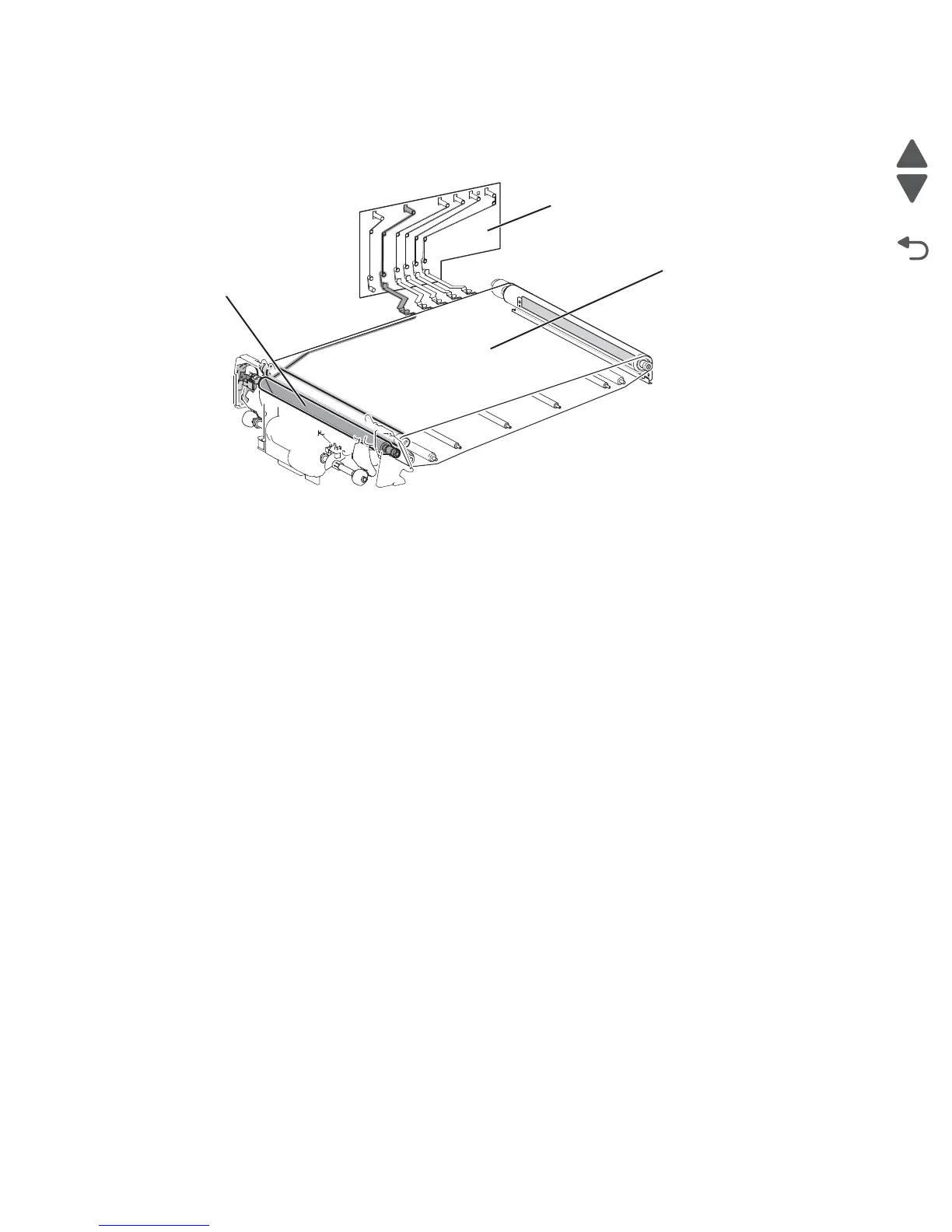

HVPS

Transfer belt

2nd transfer roll

assembly

Loading...

Loading...