Preventive maintenance 6-1

5058-030

6. Preventive maintenance

This chapter describes procedures for printer preventive maintenance. Follow these recommendations to help

prevent problems and maintain optimum performance.

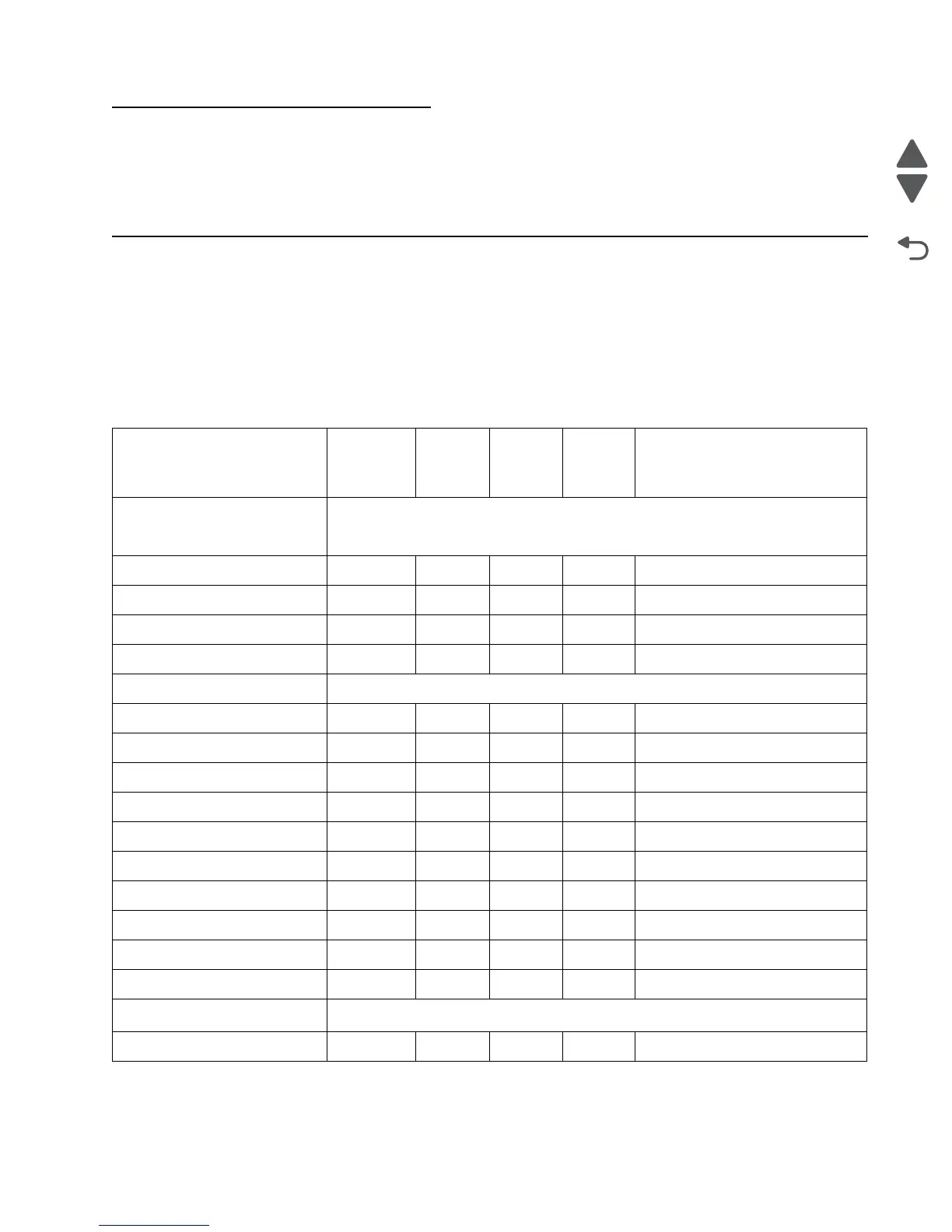

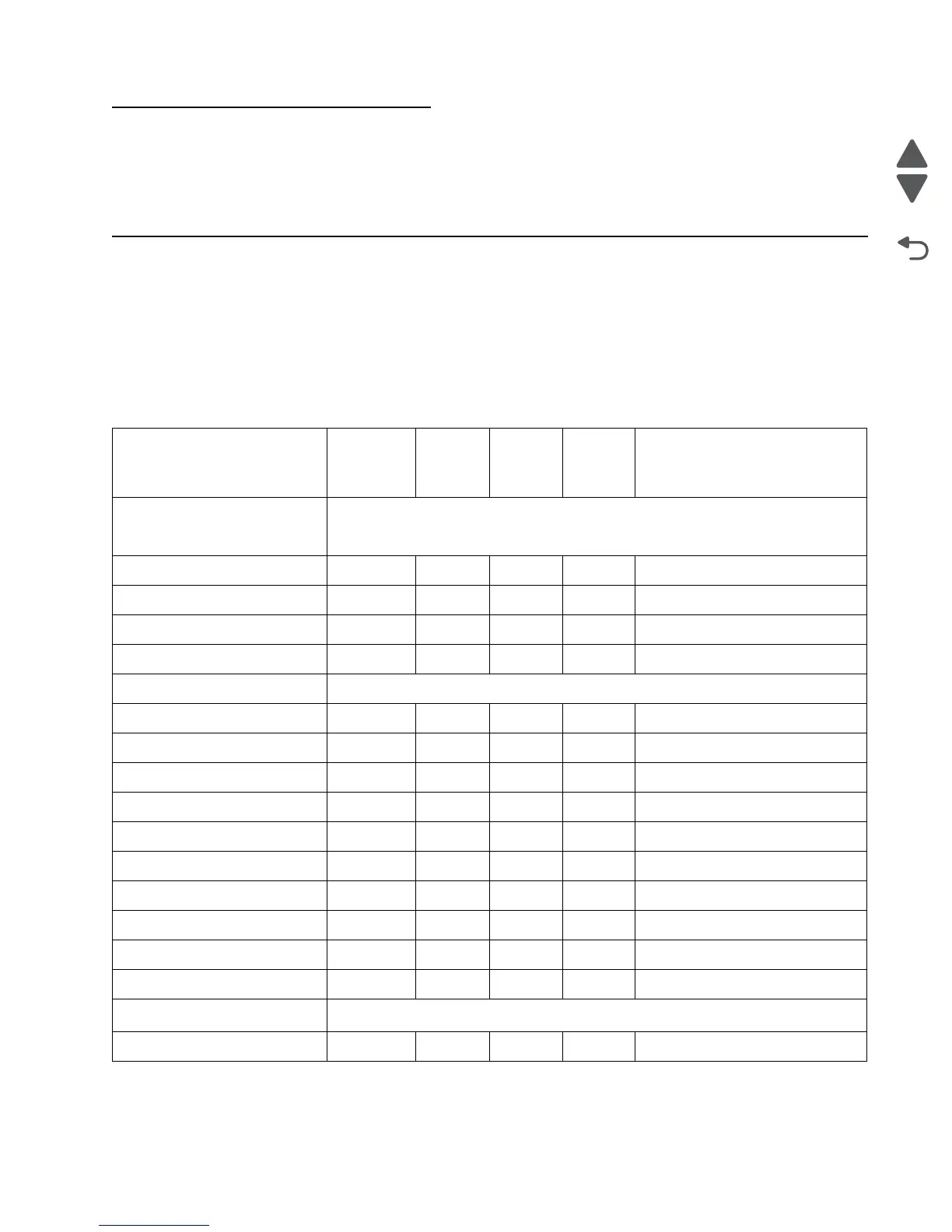

Inspection guide

The purpose of this inspection guide is to aid you in identifying the intervals, based on page count, at which parts

must be inspected (for visible physical damage), cleaned, or replaced.

As you service the machine, check the following:

• Damaged, missing, or altered parts, especially in the area of the On/Off switch and the power supply

• Damaged, missing, or altered covers, especially in the area of the top cover and the power supply cover

• Possible safety exposure from any non-Lexmark attachments

Lexmark C950

EVERY

SERVICE

CALL

EVERY

160K

EVERY

320K

EVERY

480K

NOTES

MEDIA TRAY—ALL

Media side guides Inspect Inspect Inspect Inspect Check for correct positioning

Media end guide Inspect Inspect Inspect Inspect Check for correct positioning

Separation pad Inspect Clean Clean Clean Damp cloth

Tray lift gear assembly Inspect Inspect Inspect

MEDIA FEEDERS—ALL

Feed roller Inspect Replace Replace Replace Verify page count before replacing

Pick roller Inspect Replace Replace Replace Verify page count before replacing

Separation roll Inspect Replace Replace Replace Verify page count before replacing

MPF feed rollers Inspect Inspect Inspect Clean Water or alcohol

Media transport roll assembly Clean Clean Clean Water or alcohol

Sensor (registration) Clean Clean Clean Brush or blower brush

Sensor (tray 1 feed-out) Clean Clean Clean Brush or blower brush

Sensor (tray 2 feed-out) Clean Clean Clean Brush or blower brush

Sensor (tray 3 feed-out) Clean Clean Clean Brush or blower brush

Sensor (tray 4 feed-out) Clean Clean Clean Brush or blower brush

PRINTHEAD

Printhead slit glass (4) Clean Clean Clean Clean Printhead cleaning tool

Loading...

Loading...