3-76 Service Manual

5058-030

From bridge unit assembly to punch

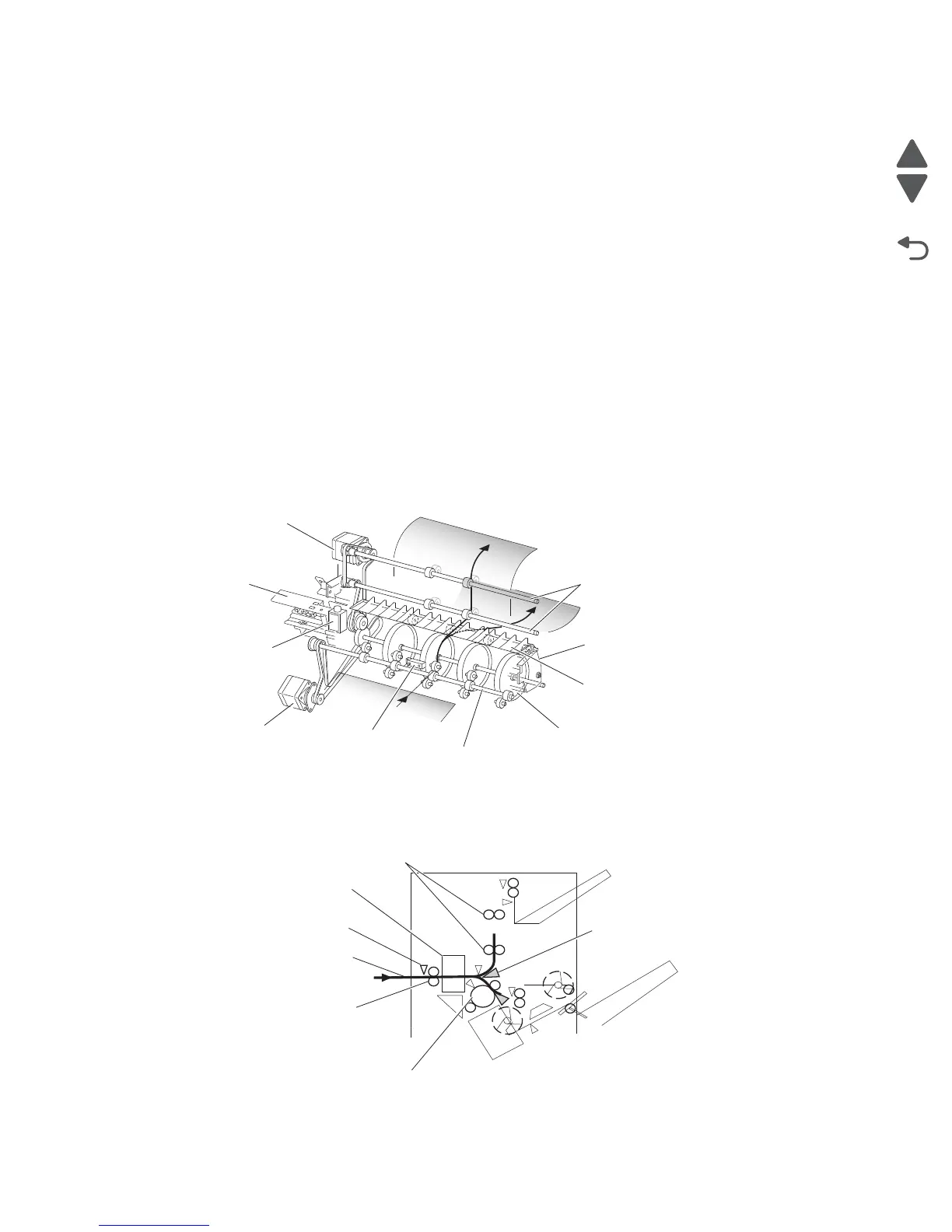

The media fed from the bridge unit assembly is fed into the finisher by the media entrance roll assembly located

on the entrance section of the finisher which is driven by the drive motor (entrance/paddle).

The media route inside the finisher is determined by the finisher diverter gate.

The finisher diverter gate is activated by the finisher diverter gate solenoid controlled by the printer.

The media is further fed in the finisher by the two upper media transport roll assemblies, or the buffer roll

assemblies that are driven by the motor (buffer/transport), and passes through the punch unit.

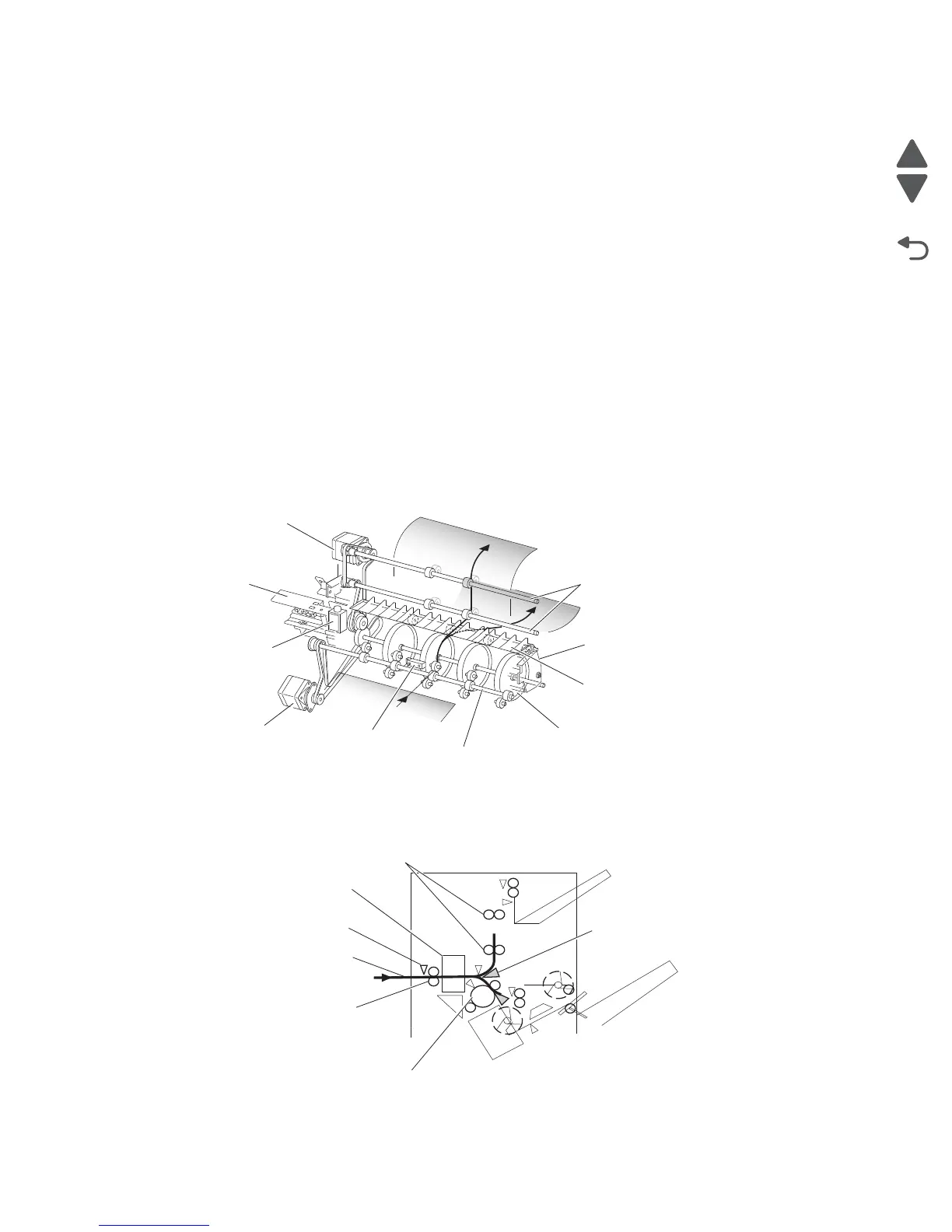

The sensor (finisher media entrance) becomes low upon detecting media. After a certain amount of time has

passed and the level has changed to high, the motor (buffer/transport) that drives the upper media transport roll

assembly or the buffer roll assembly starts reverse rotation.

The media is returned to the punch unit by the upper media transport roll assembly or the buffer roll assembly,

and is stopped with its end gently pressed against the three punch media stopper assemblies.

The three punch media stopper assemblies in the punch unit drop to let media pass through when media is fed

to the exit (while the motor (buffer/transport) is rotating forward), but rise when media is returned (while the

motor (buffer/transport) is rotating reversely) to stop the media.

Thus, punch hole positions in the media feed direction are determined.

Drive motor (buffer/transport)

Upper media transport

roll assembly

Punch unit

Buffer roll assembly

Finisher media

entrance roll

assembly

Sensor (finisher

media entrance)

Drive motor

(entrance paddle)

Punch unit

Finisher diverter

gate solenoid

Finisher diverter gate

Finisher diverter gate

Buffer roll assembly—

driven by drive motor (buffer/transport)

Finisher media entrance

roll assembly—driven by

drive motor (entrance/paddle)

Media

From bridge unit assembly

Sensor (finisher

media entrance)

Punch unit

Upper media transport roll assembly—driven by

drive motor (buffer/transport)

Loading...

Loading...