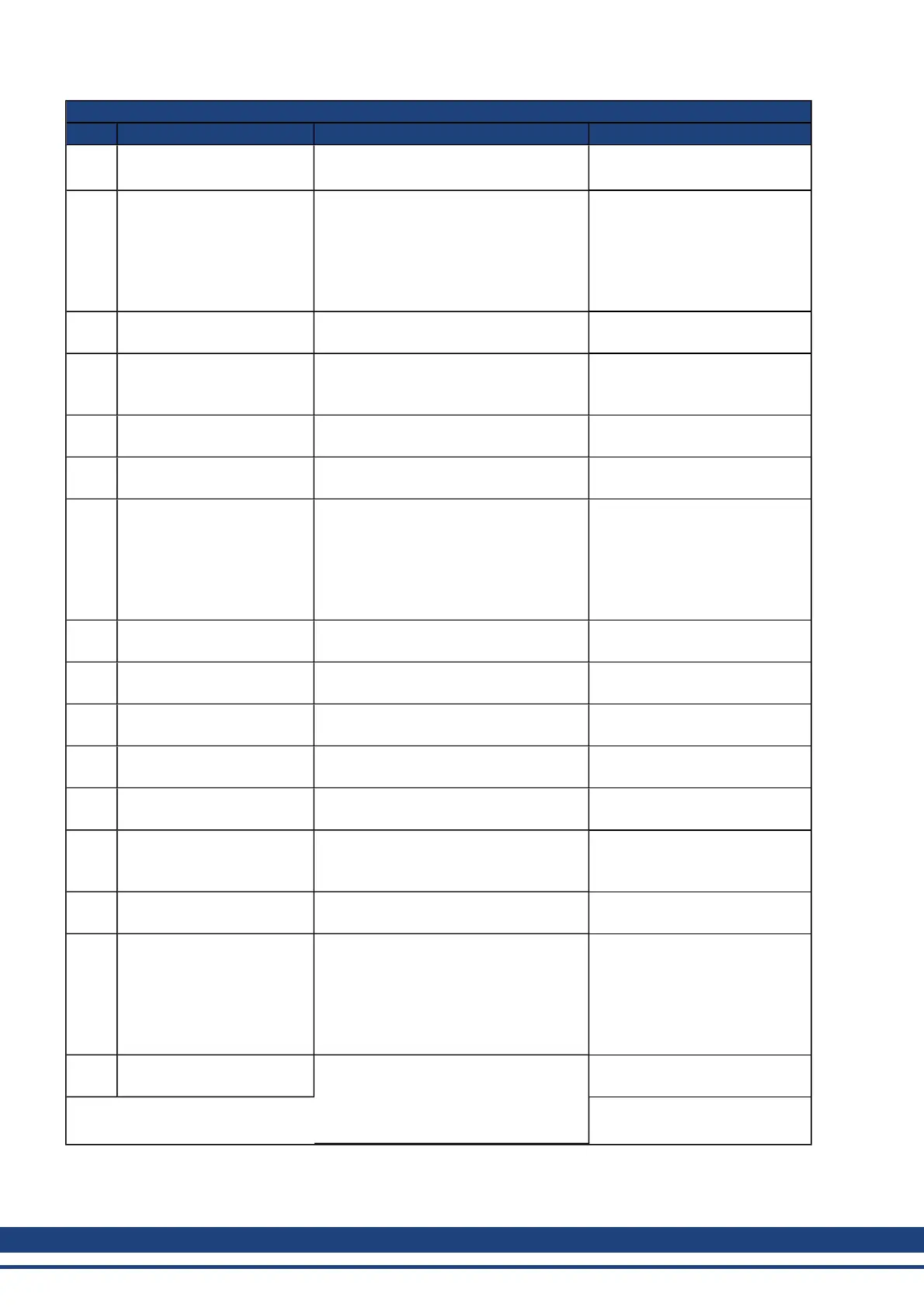

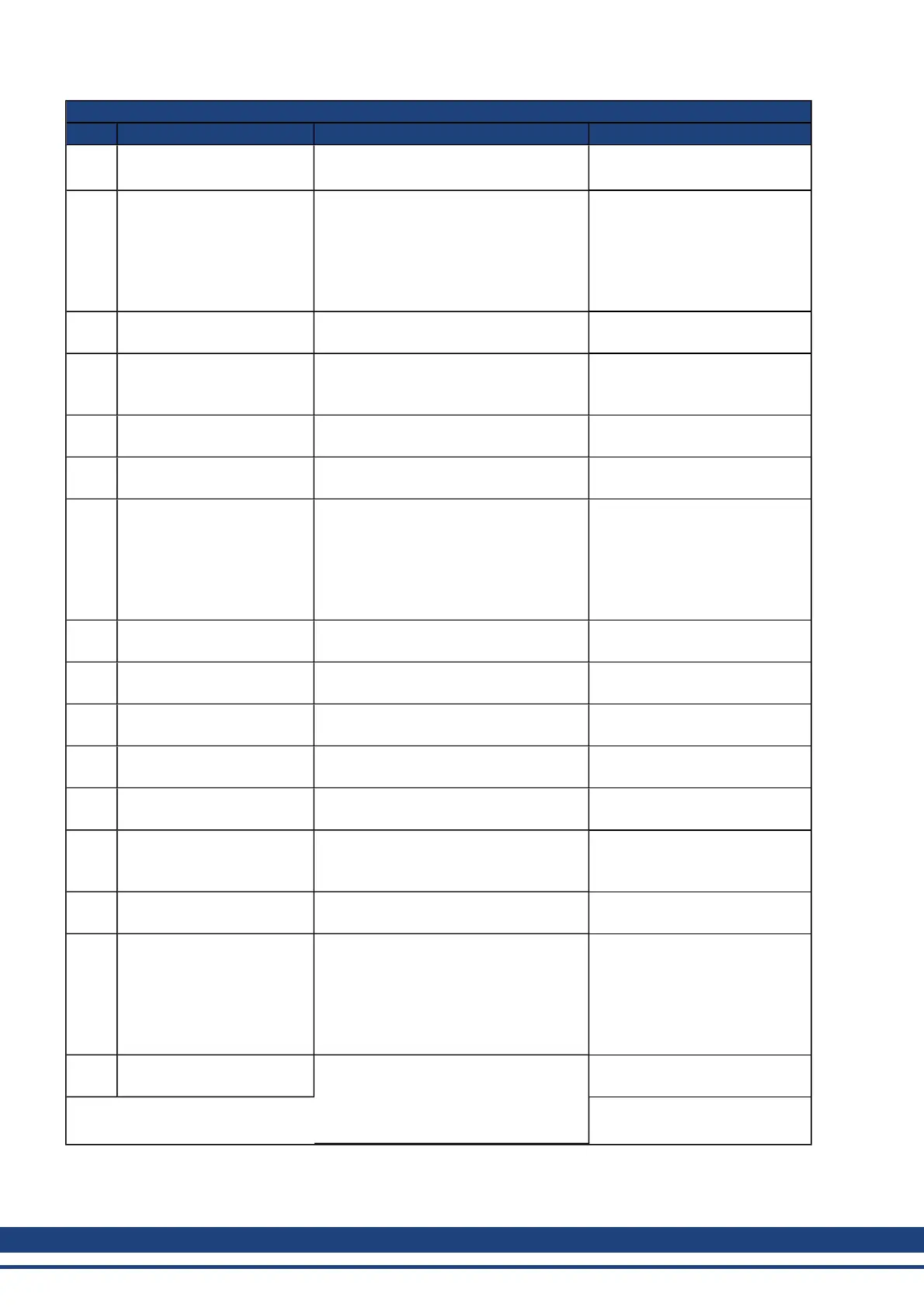

AKD User Guide | 17 Faults and Warnings

Fault Message/Warning Cause Remedy

240 to

243

Temperature sensor low.

Warning issued prior to fault.

Low temperature limit reached. Check cabinet ventilation sys-

tem.

245 External fault. This fault is user generated and is

caused by user settings.

Users can configure a digital

input to trigger this fault

(DINx.MODE = 10). The fault

occurs according to this input

setting. Clear the input to clear

the fault.

247 Bus voltage exceed allowed

thresholds.

Hardware problem in bus measurement. Troubleshoot and repair hard-

ware problem.

301 Motor overheated.

Warning issued prior to fault.

Motor overheated. Check ambient temperature.

Check motor mounting heat sink

capability

302 Over speed. Motor exceeded VL.THRESH value. Look for overshoot or lower

requested speed.

303 Runaway. Motor did not follow command values. Gains are too low; motor is being

over driven.

304 Motor foldback.

Warning issued prior to fault.

Maximum motor power has been

exceeded; the power has been limited to

protect the motor

Motion is requiring too much

power. Change move profile to

reduce load on motor. Check for

load jamming or sticking. Check

that current limits are set cor-

rectly.

305 Brake open circuit. Motor brake open circuit. Check cabling and general func-

tionality.

306 Brake short circuit. Motor brake short circuit. Check cabling and general func-

tionality.

307 Brake closed during enable

state.

Motor brake closed unexpectedly. Check cabling and general func-

tionality.

308 Voltage exceeds motor rat-

ing.

Drive bus voltage exceeds the motor’s

defined voltage rating.

Make sure that the motor fits the

driving rating.

401 Failed to set feedback type. Feedback is not connected or wrong

feedback type selected

Check primary feedback (X10

connection).

402 Analog signal amplitude

fault.

Analog signal amplitude is too low.

Analog fault (resolver signal amplitude or

sin/cos amplitude)

Check primary feedback (X10

connection), resolver and

sine/cos encoder only.

403 EnDat communication fault. General communication problem with

feedback.

Check primary feedback (X10

connection), EnDat only

404 Hall error. Hall sensor returns invalid Hall state

(111, 000); either all Hall sensors are on

or off. Legal Hall states are 001, 011,

010, 110, 100, and 101. This fault can be

caused by a broken connection in any

one of the Hall signals.

Check the feedback wiring;

check all feedback connectors

to ensure all pins are positioned

correctly.

405 BiSS watchdog fault. Bad communication with the feedback

device.

Check primary feedback (X10

connection), Biss only.

212 Kollmorgen | December 2010

Loading...

Loading...