Foldback is not the same as current limits. Instantaneous current limits for the drive are set by the positive peak

current (IL.LIMITP) and negative peak current (IL.LIMITN) in the Limits view in WorkBench. The foldback algo-

rithms may reduce the current output to the motor in spite of the current limit settings.

8.8.1 Drive Foldback

The drive foldback algorithm monitors current feedback; since this is a monitoring function, the drive foldback

parameters are not user configurable. If the current feedback exceeds the continuous current rating of the drive

(DRV.ICONT), then the algorithm decreases the current to the DRV.ICONT level. For example, under a step

command input condition, the foldback algorithm allows maximum peak current (DRV.IPEAK) output from the

drive for a short period of time (up to IL.DFOLDD time), after which the drive begins an exponential foldback (with

time constant of IL.DFOLDT) of the current to the drive’s continuous current.

It takes a few seconds for the exponential decay to drop from the drive’s peak current to its continuous level. A

recovery time, where the feedback current is below DRV.ICONT level, is required to allow current above

DRV.ICONT level again. A recovery time of IL.DFOLDR with 0 current allows the drive to apply DRV.IPEAK cur-

rent for IL.DFOLDD time.

8.8.2 Setting up motor foldback

Motor foldback is set up automatically when using a plug and play motor or when a particular motor is selected

from the WorkBench database.

If you are using a custom motor, use the Motor view in WorkBench to set custom values needed for foldback con-

figuration.The parameter entries required for the drive to apply motor foldback protection properly are coil thermal

constant (MOTOR.CTFO), peak current of the motor (MOTOR.IPEAK), and continuous current of the motor

(MOTOR.ICONT). These values are used to setup the algorithm for motor foldback.

8.8.3 Setting Fault and Warning Levels

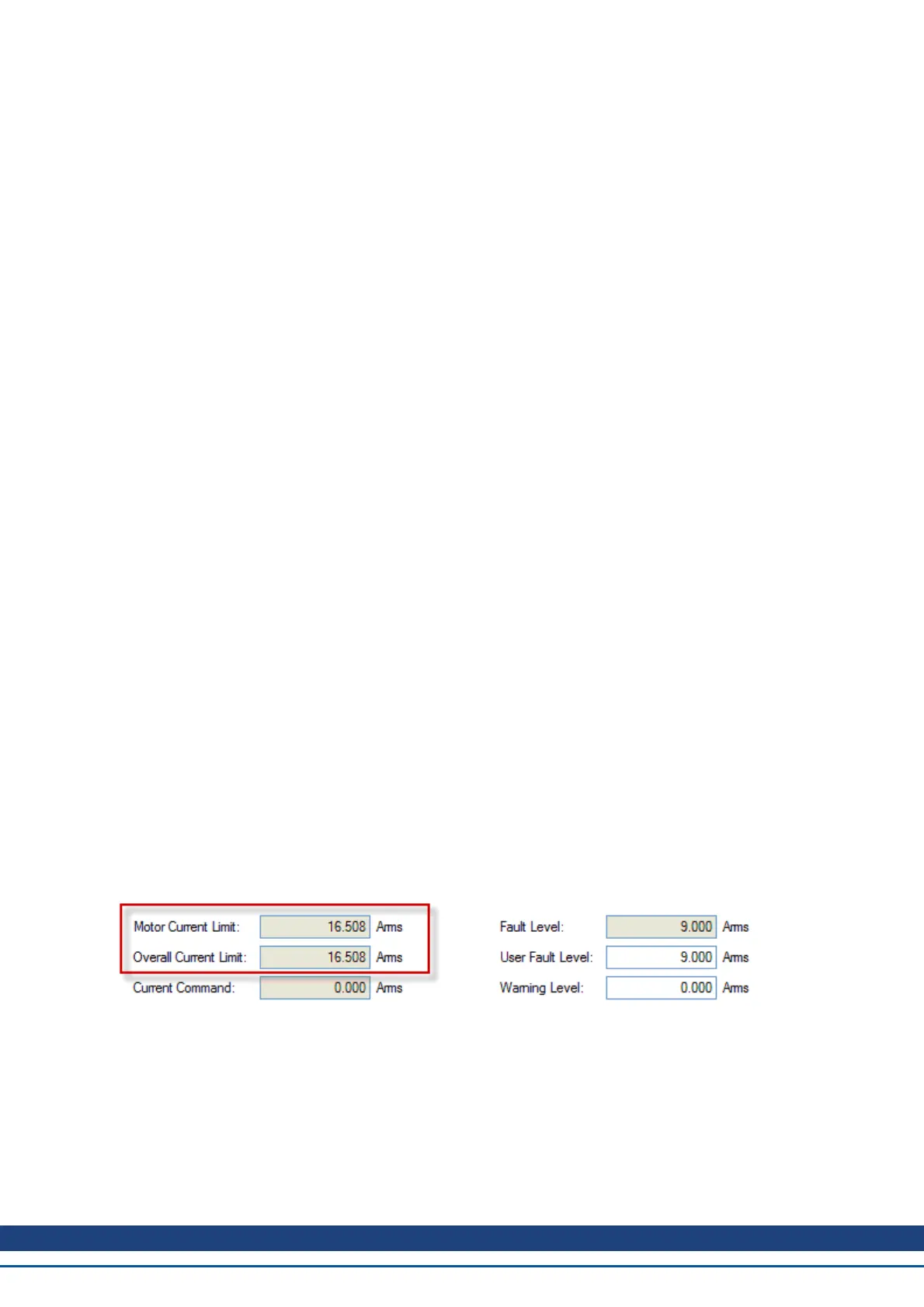

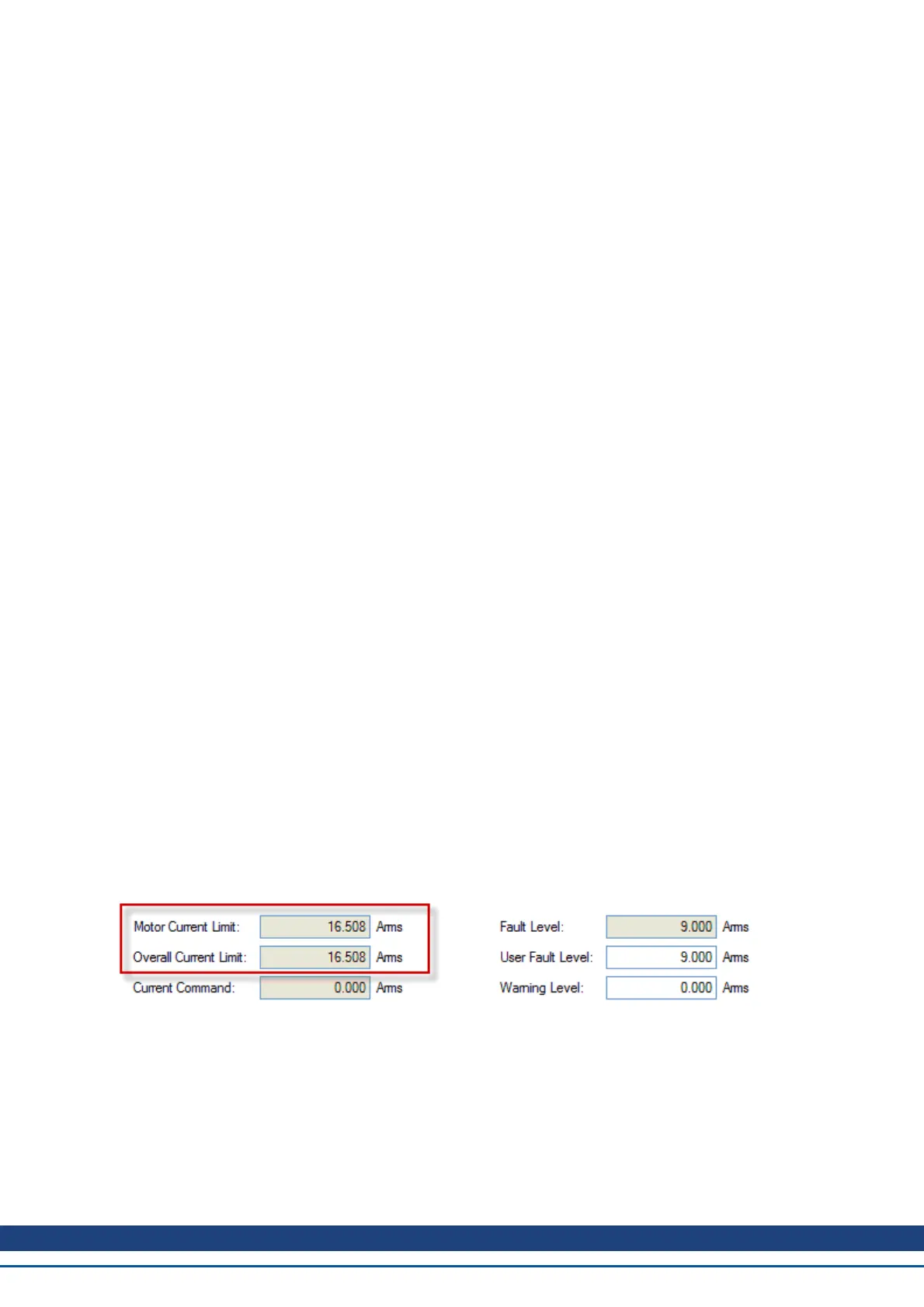

The Motor Current Limit and Overall Current Limit boxes show status variables that are constantly updated

by the foldback algorithm. As current is applied above the drive or motor continuous rating, the capacity for the

application of peak current starts to decrease. The motor current limit and overall current limit are actively

decreased. If the move profile requires less than continuous current rating for a period of time, the Motor Current

Limit and Overall Current Limit begin to increase until they reach maximum foldback capacity once again.

When Motor Current Limit or Overall Current Limit < Warning Level, an n524 status warning is triggered. When

Motor Current Limit or Overall Current Limit < Fault Level, an F524 fault is triggered and the drive power stage is

disabled. The load then coasts to a stop.

In the Foldback screen, setting the Warning Level to 0 turns off the warning feature. Otherwise, the Warning

Level must be set above the Fault Level, but below the Motor Current Limit and Overall Current Limit to trigger a

warning.

If User Fault Level is set above Fault Level, the User Fault Level will be ignored. The User Fault Level is used to

increase the time the drive is operated in foldback mode without faulting. For instance if the default Fault Level is

9.000 Arms and a User Fault Level is set to 7.5 Arms, the Fault Level is changed to 7.5 Arms. This configuration

effectively increases the time that foldback will be applied to the drive before faulting.

AKD User Guide | 8 Configuring Motor Settings

Kollmorgen | December 2010 73

Loading...

Loading...