14.4.4 Closed Loop Tuning Methods

The closed loop control loop is responsible for the desired position and / or velocity (trajectory) of the motor and

commanding the appropriate current to the motor to achieve that trajectory. The challenge in closed loop control

loops is to make a system that not only follows the desired trajectory, but also is stable in all conditions and

resist external forces, and do all of this at the same time.

When in velocity operation mode, only the velocity loop is tuned. When in position operation mode, both the

velocity and position loops must be tuned.

14.4.4.1 Tuning the Velocity Loop

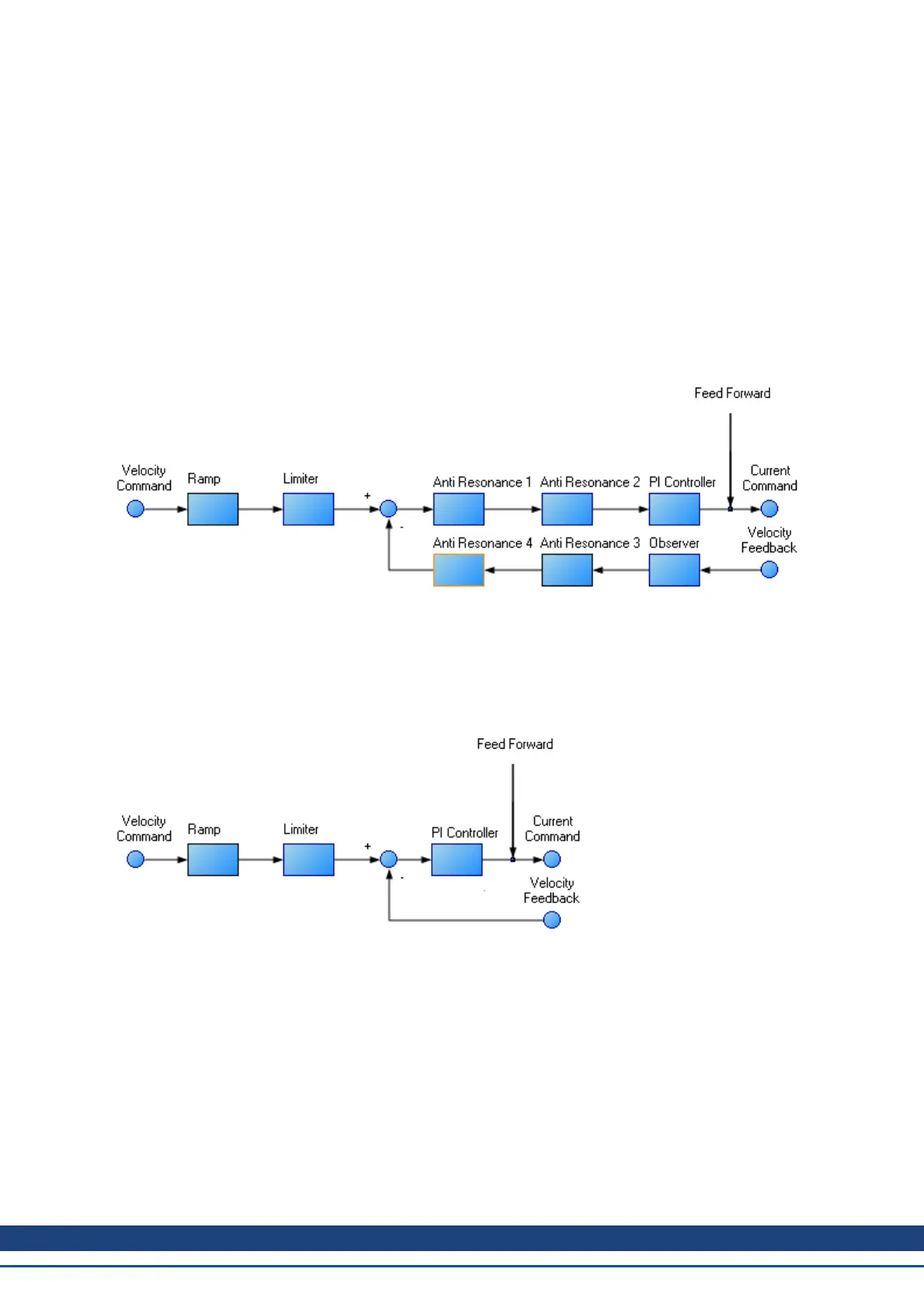

The velocity loop on the AKD consists of a PI (proportional, integral) in series with two anti resonance filters

(ARF) in the forward path and two anti resonance filters in series in the feedback path.

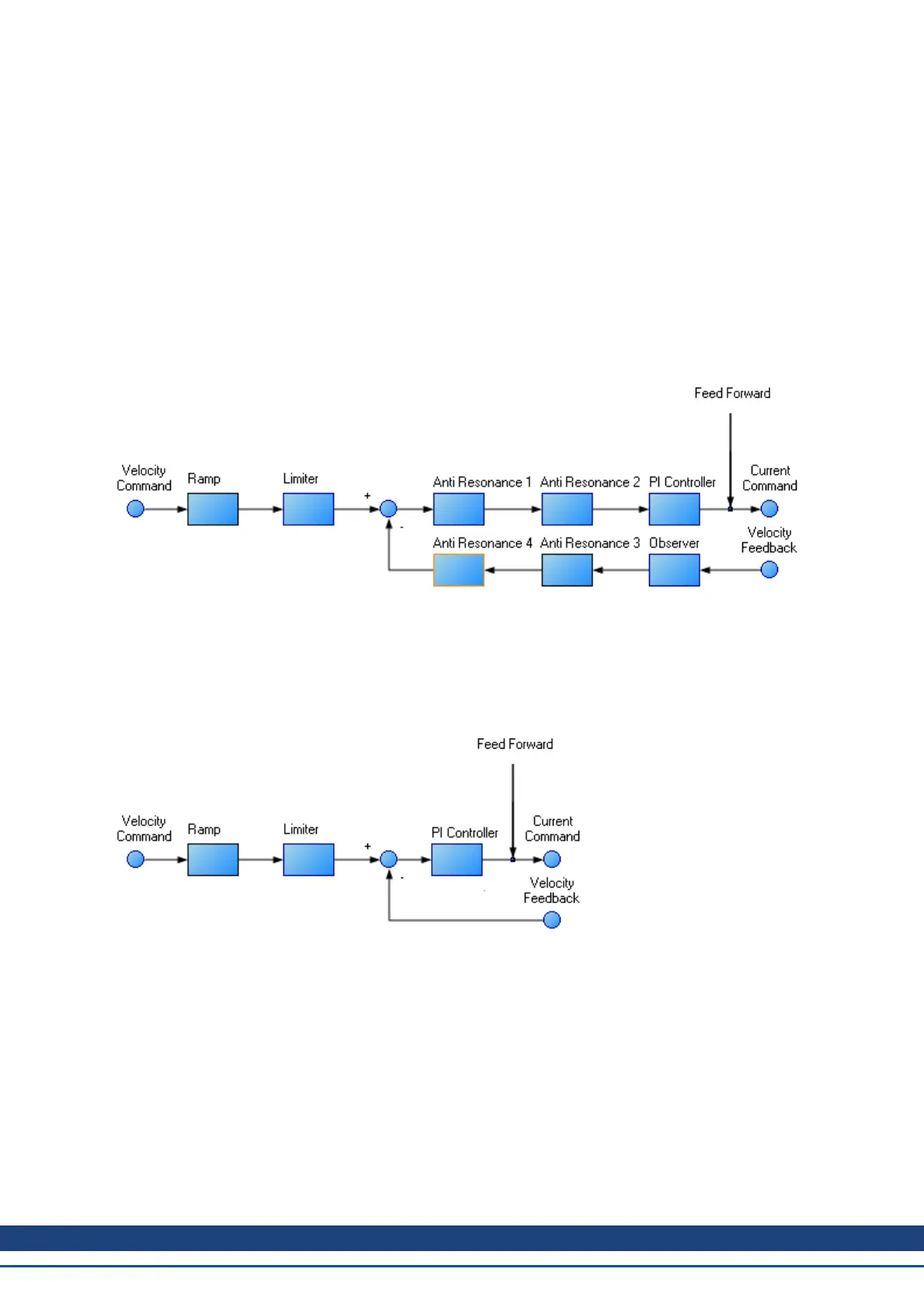

To perform basic tuning of the velocity loop, you can use just the PI block and set ARF1 and ARF2 to unity (no

effect) and set the observer to 0 (no effect). Using just the PI block simplifies the process of tuning the velocity

loop. To start tuning you can adjust the PI Controller block first. A simplified velocity loop without anti resonant

filters and observer is shown below. This is how you can think of the loop before the anti resonant filters and

observer is used.

Procedure for simple velocity loop tuning:

1. Set DRV.OPMODE to velocity or position, as appropriate for your application. If DRV.OPMODE is set to

position, set VL.KVFF to 1.0.

2. Set VL.KP to 0.

3. Set VL.KI to 0.

4. Set service motion to make a motion that is similar to the move speeds that will be used in the real appli-

cation. Do not set the service motion to a speed higher than ½ of the maximum motor speed, to allow for

safe overshoot during tuning. Set acceleration to an appropriate value for your application. Set service

motion to reversing. Set time1 and time2 equal to 3 times the expected settling time for the system. 1.0

second is a reasonable value for time1 and time2, if you don’t know the expected settling time.

AKD User Guide | 14 Tuning Your System

Kollmorgen | December 2010 165

Loading...

Loading...