l When you reach one of the limits above, decrease VL.KI to the value where there were no objec-

tionable noises or overshoot.

9. Stop the service motion

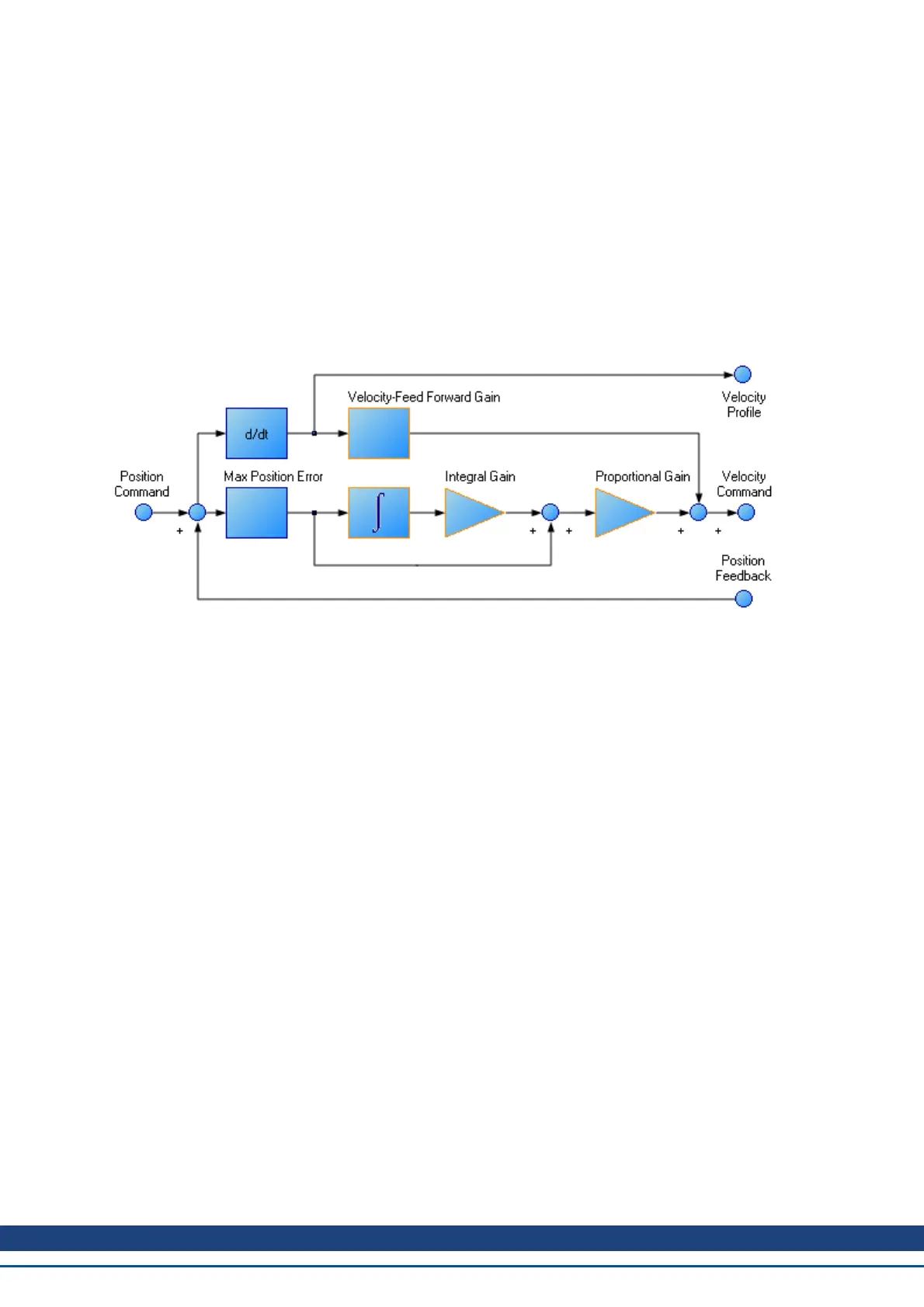

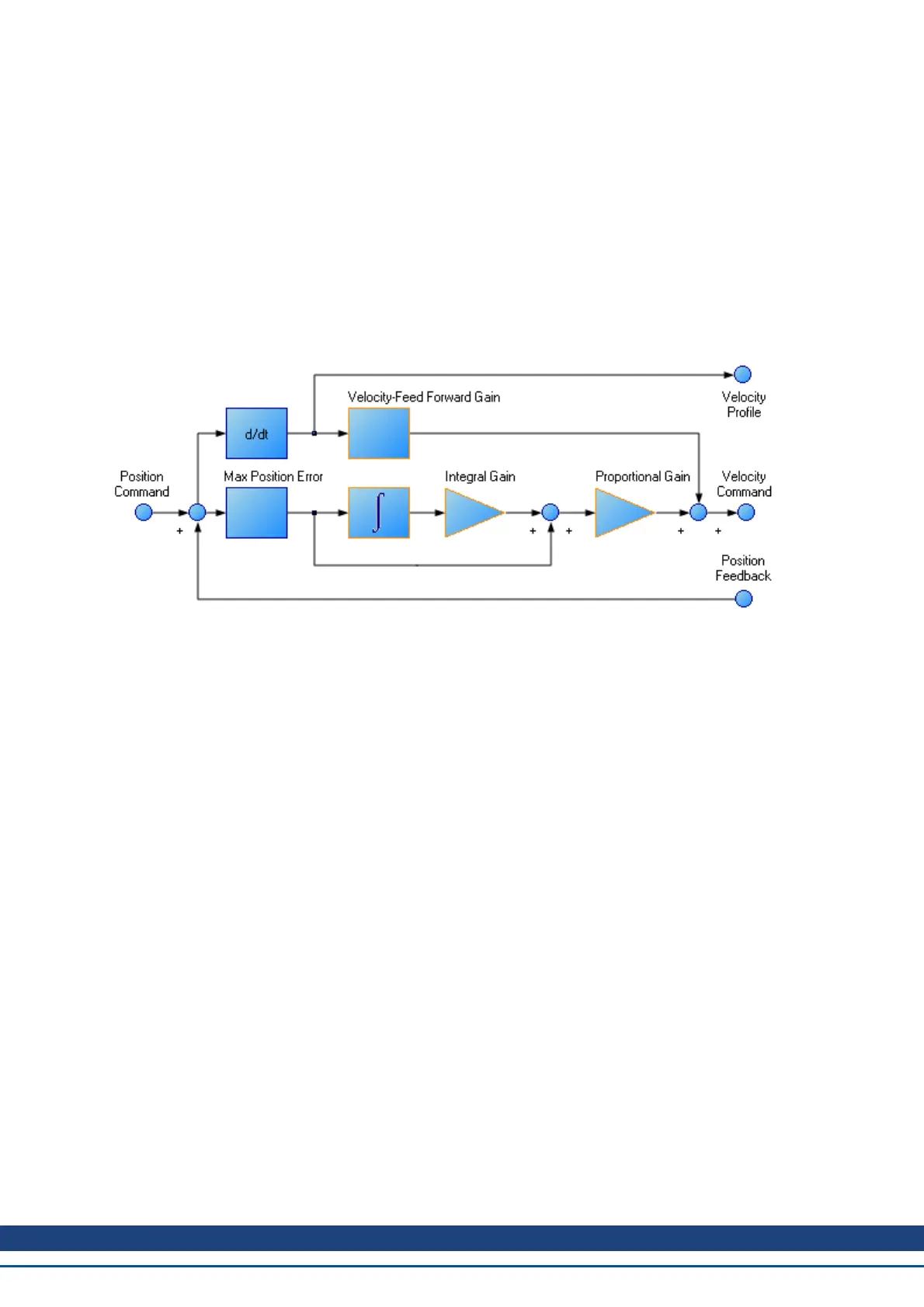

14.4.4.2 Tuning the Position Loop

The position loop is a second loop that builds upon a correctly tuned velocity loop to provide accurate control over

position. The position loop is a simple element that consists of a PI loop. It is simplest to tune the P and I terms

in the velocity loop and use only the P term in the position loop.

At most, use only three non-zero P and I terms from both the velocity loop and the position loop. One com-

bination would be VL.KP, VL.KI, and PL.KP. Another valid combination would be VL.KP, PL.KP, and PL.KI. The

VL.KP, VL.KI, and PL.KP combination is shown here.

Procedure for tuning position loop:

1. Set VL.KVFF to 1

2. Increase PL.KP until either:

l You see 25% overshoot

l You see > 3 overshoots

l You hear objectionable noises from the system.

l When you reach one of the limits above, decrease PL.KP to the value where there were no objec-

tionable noises or overshoot.

14.4.5 Torque Feedforward Tuning Methods

The torque based feedforward terms on the AKD effectively model the physics of your motor and allow the drive

to command the appropriate current, even before the encoder has time to send data back to the drive. Torque

based feedforward terms allow you to lower following error with virtually no stability penalty.

14.4.5.1 Shape Based Feedforward Tuning

To adjust IL.KAFF:

l Tune the VL.KP and VL.KI as shown above in the velocity loop tuning section. Set DRV.OPMODE to

velocity (or set PL.KP and PL.KI to 0 and vl.kvff to 1).

l Set up a short, repeating service motion with accelerations that are representative of the moves you

will use in your application (exact values for acceleration are not critical).

l Turn up IL.KAFF until the position error (PL.ERR) is proportional to the inverted velocity command.

The adjustment of IL.KAFF will focus on removing bumps on acceleration and deceleration. The pic-

AKD User Guide | 14 Tuning Your System

Kollmorgen | December 2010 167

Loading...

Loading...