Parameterization

The arrangement of the parameter data is performed with Automation Builder software.

The parameter data directly influences the functionality of modules.

For non-standard applications, it is necessary to adapt the parameters to your system configu-

ration.

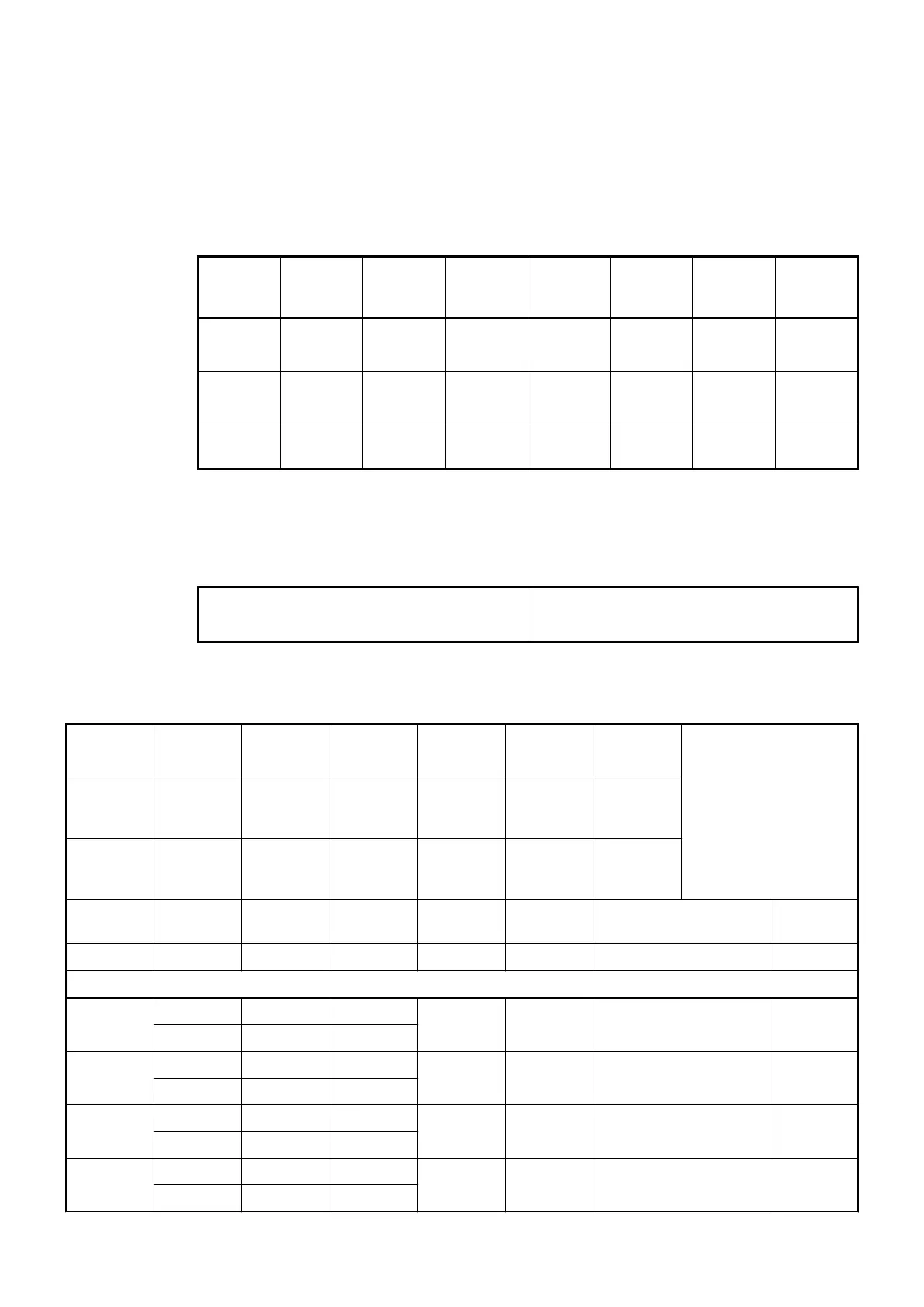

Name Value Internal

Value

Internal

Value,

Type

Default Min. Max. EDS Slot

Index

Module ID Internal

6120

1

)

WORD 6120

0x17E8

0 65535 xx01

Ignore

module

No

Yes

0

1

BYTE No

(0x00)

Parameter

length

Internal 1 BYTE 0 0 255

xx02

2

)

1

) with CS31 and addresses smaller than 70, the value is increased by 1

2

) Value is hexadecimal: HighByte is slot (xx: 0...7), LowByte is index (1...n)

GSD file:

Ext_User_Prm_Data_Len =

Ext_User_Prm_Data_Const(0) =

0x03

0xE9, 0x17, 0x00;

Diagnosis

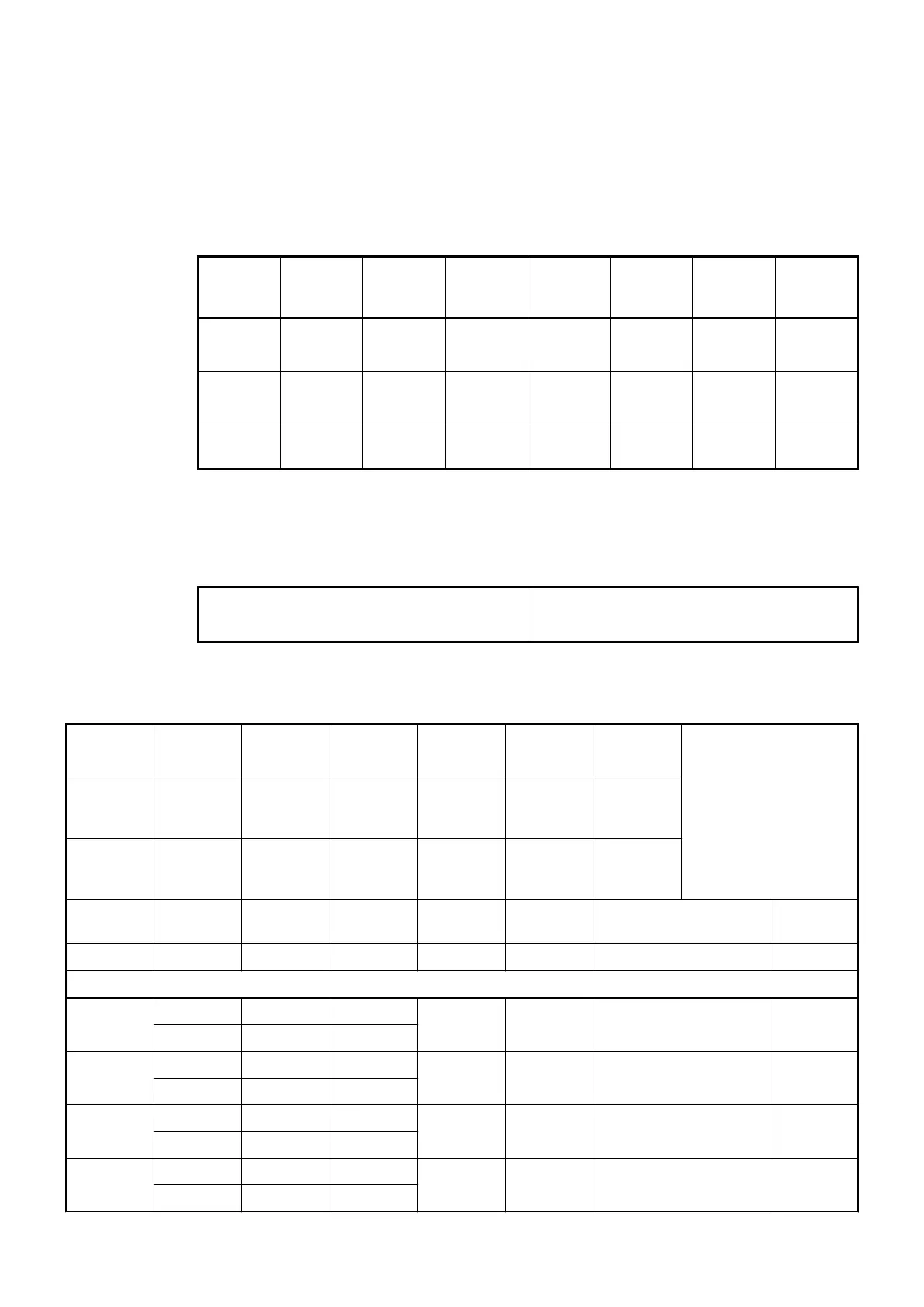

E1...E4 d1 d2 d3 d4 Identifier

000...063

AC500-

Display

<− Display in

Class Comp Dev Mod Ch Err PS501

PLC

Browser

Byte 6

Bit 6...7

- Byte 3 Byte 4 Byte 5 Byte 6

Bit 0...5

PNIO

diagnosis

block

Class Interface Device Module Channel Error

Identifier

Error message Remedy

1

)

2

)

3

)

4

)

Module error DO561

3 14 1...10 31 31 19 Checksum error in the

I/O module

Replace

I/O module

11 / 12 ADR 1...10

3 14 1...10 31 31 43 Internal error in the

module

Replace

I/O module

11 / 12 ADR 1...10

3 14 1...10 31 31 9 Overflow diagnosis

buffer

Restart

11 / 12 ADR 1...10

3 14 1...10 31 31 26 Parameter error Check

master

11 / 12 ADR 1...10

I/O Modules > Digital I/O Modules

2019/04/17 3ADR010121, 13, en_US 227

Loading...

Loading...