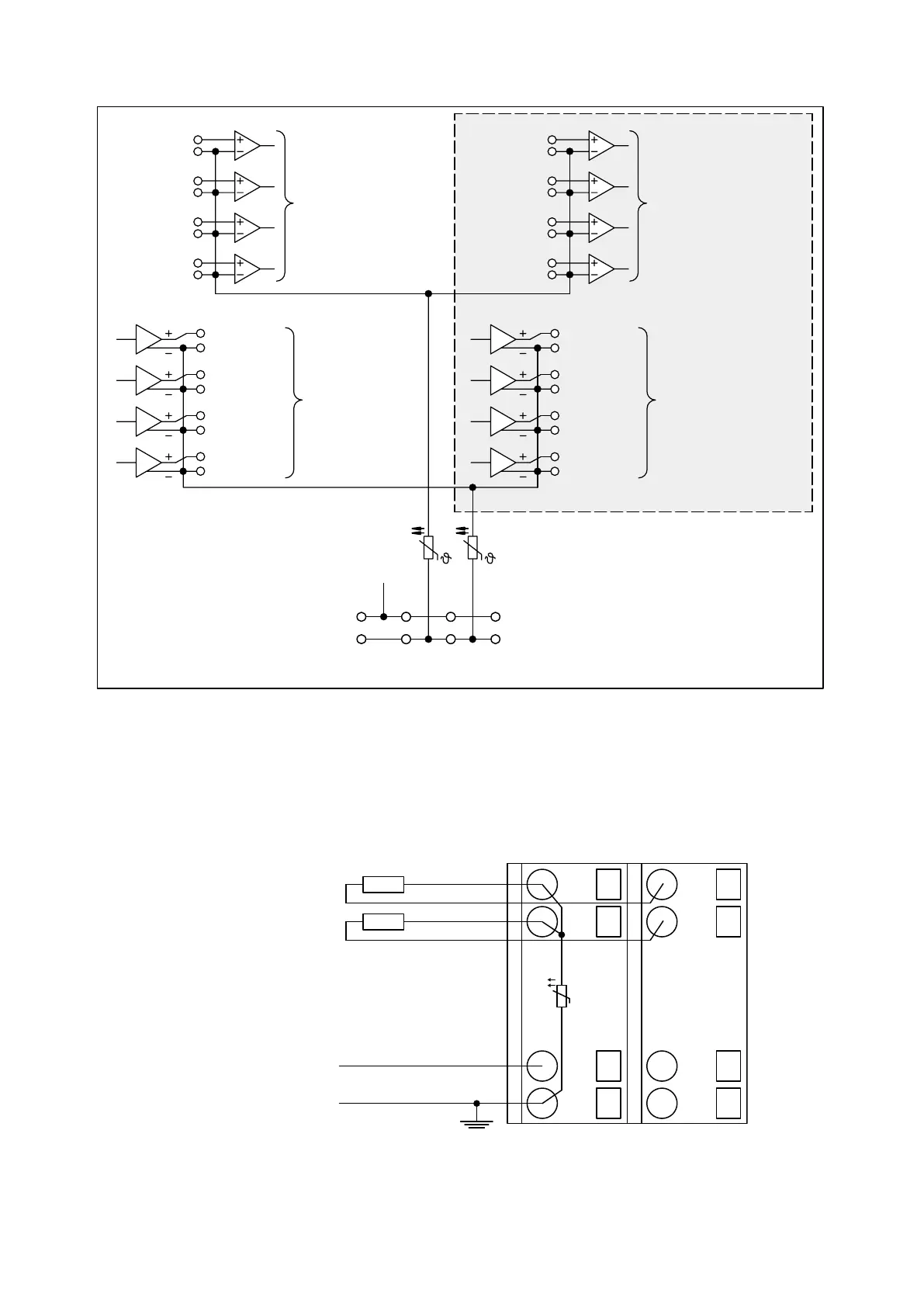

2.0

1.0

I0+

I0–

2.1

1.1

I1+

I1–

2.2

1.2

I2+

I2–

2.3

1.3

I3+

I3–

2.4

1.4

I4+

I4–

2.5

1.5

I5+

I5–

2.6

1.6

I6+

I6–

2.7

1.7

I7+

I7–

O0+

O0–

4.0

3.0

O4+

O4–

4.4

3.4

O1+

O1–

4.1

3.1

O5+

O5–

4.5

3.5

O2+

O2–

4.2

3.2

O6+

O6–

4.6

3.6

O3+

O3–

4.3

3.3

O7+

O7–

4.7

3.7

AGND

AGND

UP

ZP

1.8 2.8 3.8 4.8

1.9 2.9 3.9 4.9

+24 V

0 V

4 analog inputs

for 0...10 V,

–10 V...+10 V,

0/4... 20 mA,

Pt100 / Pt1000,

Ni1000 and

digital signals

4 analog

outputs for

–10 V...+10 V,

0/4... 20 mA

4 analog

outputs for

–10 V...+10 V

PTCPTC

4 analog inputs

for 0...10 V,

–10 V...+10 V,

0/4... 20 mA,

Pt100 / Pt1000,

Ni1000 and

digital signals

These I/Os only with AX522

Attention:

By installing equipotential

bonding conductors between

system, it must be made sure

that the potential difference

between ZP and AGND never

the different parts of the

can exceed 1 V.

Attention:

The process voltage must be

included in the earthing concept

of the control system

(e.g. earthing the minus pole).

Fig. 69: Terminal assignment

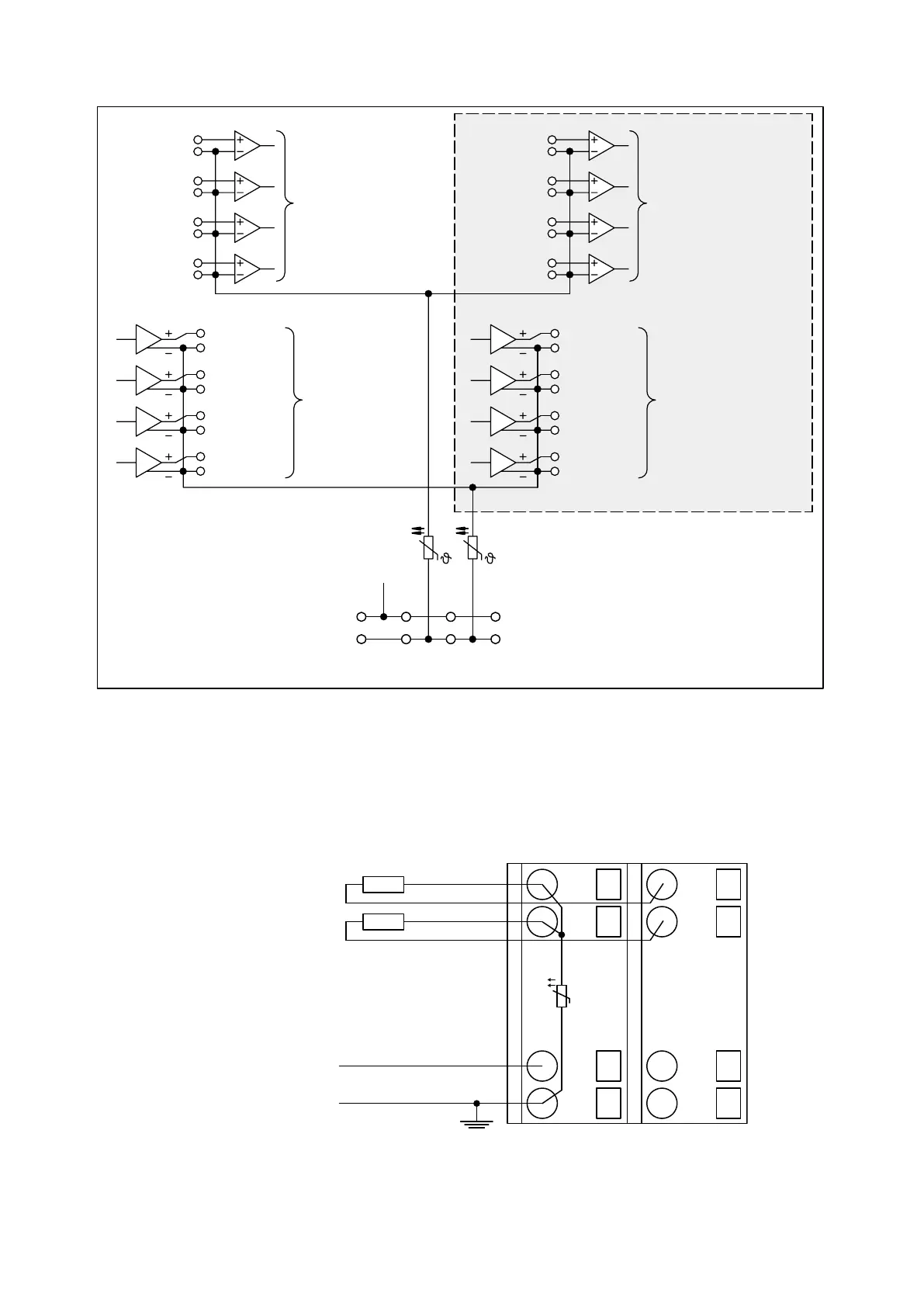

Connection of Resistance Thermometers in 2-wire Configuration

When resistance thermometers (Pt100, Pt1000, Ni1000) are used, a constant current must flow

through them to build the necessary voltage drop for the evaluation. For this, the I/O module

provides a constant current source which is multiplexed over the 8 analog channels.

UP

ZP

1.0

I0-

1.1

I1-

1.8

UP

1.9

ZP

PTC

2.0

I0+

2.1

I1+

2.8

UP

2.9

ZP

Pt100

Pt1000

Ni1000

Fig. 70: Connection example

I/O Modules > Analog I/O Modules

2019/04/173ADR010121, 13, en_US548

Loading...

Loading...