NOTICE!

Risk of damaging the PLC modules!

Overvoltages and short circuits might damage the PLC modules.

– Make sure that all voltage sources (supply and process voltage) are

switched off before you begin with operations at the system.

– Never connect any voltages or signals to reserved terminals (marked with

---). Reserved terminals may carry internal voltages.

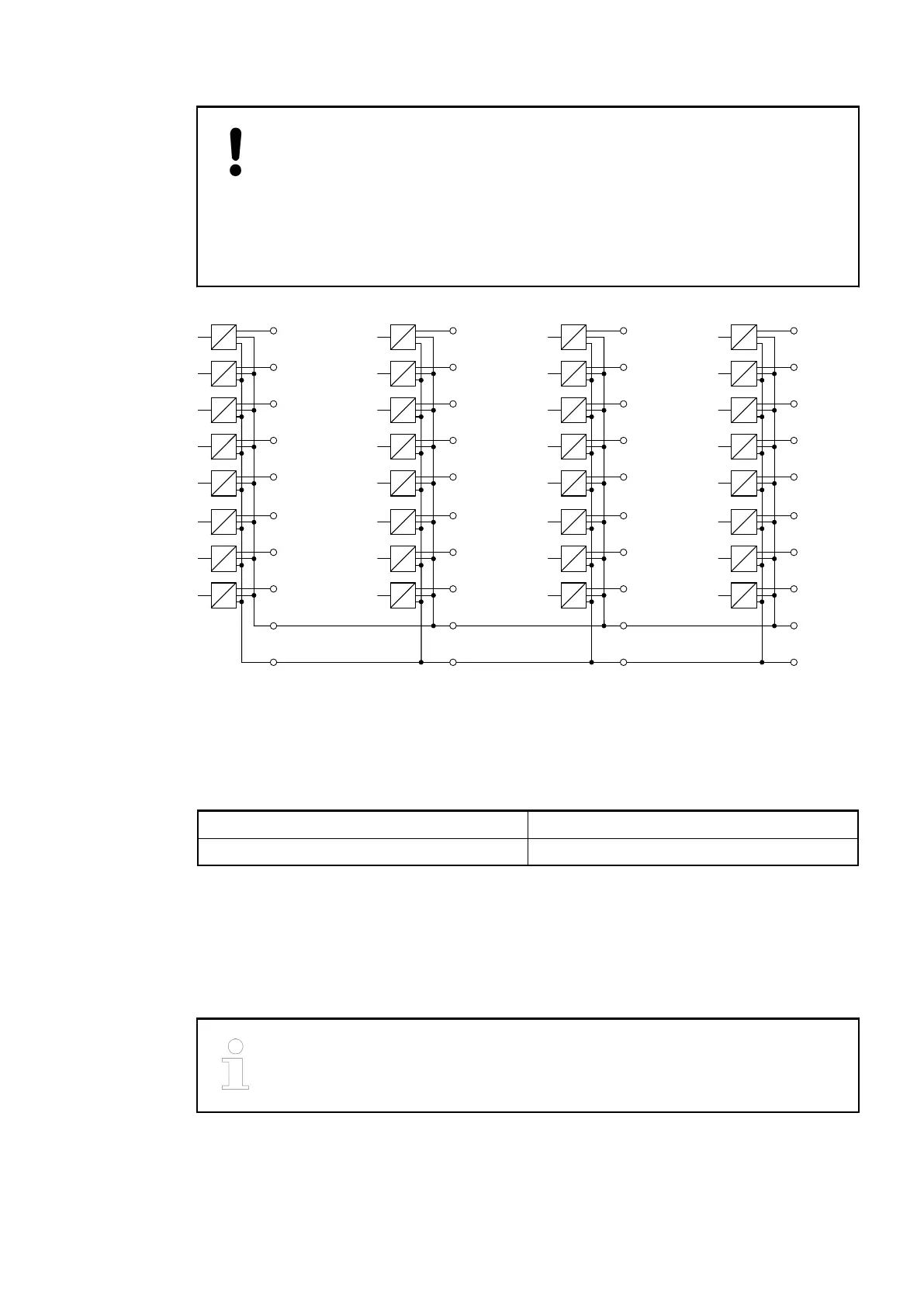

The following block diagram shows the internal construction of the digital outputs:

4.0 O 24

4.1 O 25

4.2 O 26

4.3 O 27

4.4 O 28

4.5 O 29

4.6 O 30

4.7 O 31

4.9

4.8

1.0 O 0

1.1 O 1

1.2 O 2

1.3 O 3

1.4 O 4

1.5 O 5

1.6 O 6

1.7 O 7

1.9

1.8

ZP 0 V

UP +24 V

2.0 O 8

2.1 O 9

2.2 O 10

2.3 O 11

2.4 O 12

2.5 O 13

2.6 O 14

2.7 O 15

2.9

2.8

3.0 O 16

3.1 O 17

3.2 O 18

3.3 O 19

3.4 O 20

3.5 O 21

3.6 O 22

3.7 O 23

3.9

3.8

The module provides several diagnosis functions

Ä

Chapter 1.5.1.2.6.7 “Diagnosis”

on page 357.

Internal Data Exchange

Digital inputs (bytes) 0

Digital outputs (bytes) 4

I/O Configuration

The module itself does not store configuration data. It receives its parameterization data from

the master device of the I/O bus (CPU or bus module) during power-up of the system.

Hence, replacing I/O modules is possible without any re-parameterization via software.

If the external power supply voltage via UP/ZP terminals fails, the I/O module

loses its configuration data. The whole station has to be switched off and on

again to re-configure the module.

I/O Modules > Digital I/O Modules

2019/04/17 3ADR010121, 13, en_US 355

Loading...

Loading...