NOTICE!

Risk of faulty measurements!

The negative pole/earthing potential at the sensors must not have too large a

potential difference with respect to ZP (max. ± 1 V within the full signal range).

Make sure that the potential difference never exceeds ± 1 V.

CAUTION!

The process supply voltage must be included within the earthing concept of the

plant (e. g. earthing of the minus pole).

The module provide several diagnosis functions

Ä

Chapter 1.7.3.1.8 “Diagnosis” on page 848.

The measuring ranges are described in the section Measuring Ranges

Ä

Chapter 1.7.3.1.7

“Parameterization” on page 842

Ä

Chapter 1.7.3.1.10 “Measuring Ranges” on page 851.

The function of the LEDs is described in the section State LEDs

Ä

Chapter 1.7.3.1.8 “Diag-

nosis” on page 848.

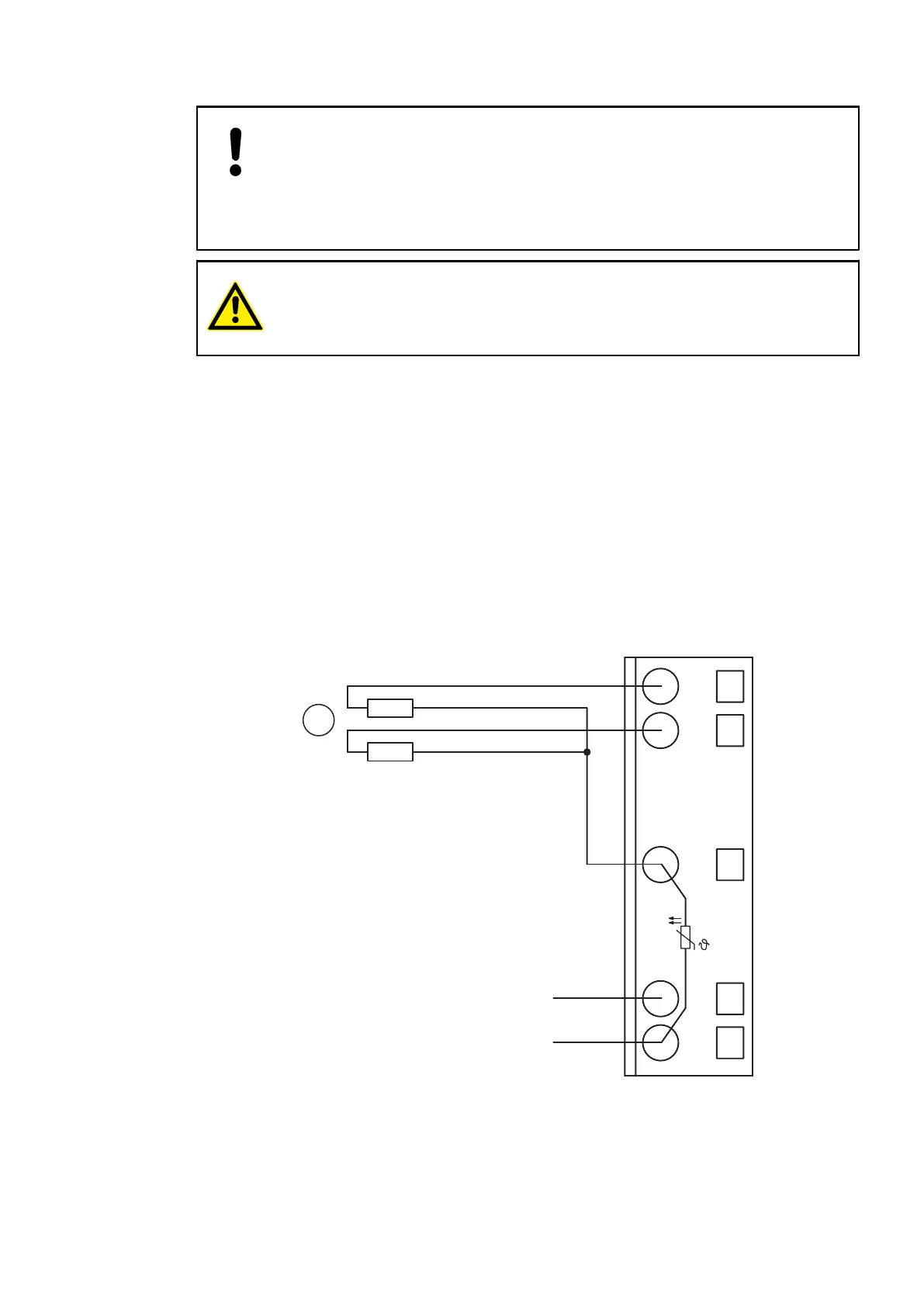

Connection of Resistance Thermometers in 2-wire Configuration

When resistance thermometers (Pt100, Pt1000, Ni1000) are used, a constant current must flow

through them to build the necessary voltage drop for the evaluation. For this, the module CI511-

ETHCAT provides a constant current source which is multiplexed over the max. 4 analog input

channels.

The following figure shows the connection of resistance thermometers in 2-wire configuration.

1.0

1.1

1.8

1.9

AI0+

AI1+

UP

ZP

UP

ZP

PTC

1.5

AI–

1

Fig. 160: Connection of resistance thermometers in 2-wire configuration

1 Pt100 (2-wire), Pt1000 (2-wire), Ni1000 (2-wire); 1 analog sensor requires 1 channel

Communication Interface Modules (S500) > EtherCAT

2019/04/173ADR010121, 13, en_US832

Loading...

Loading...