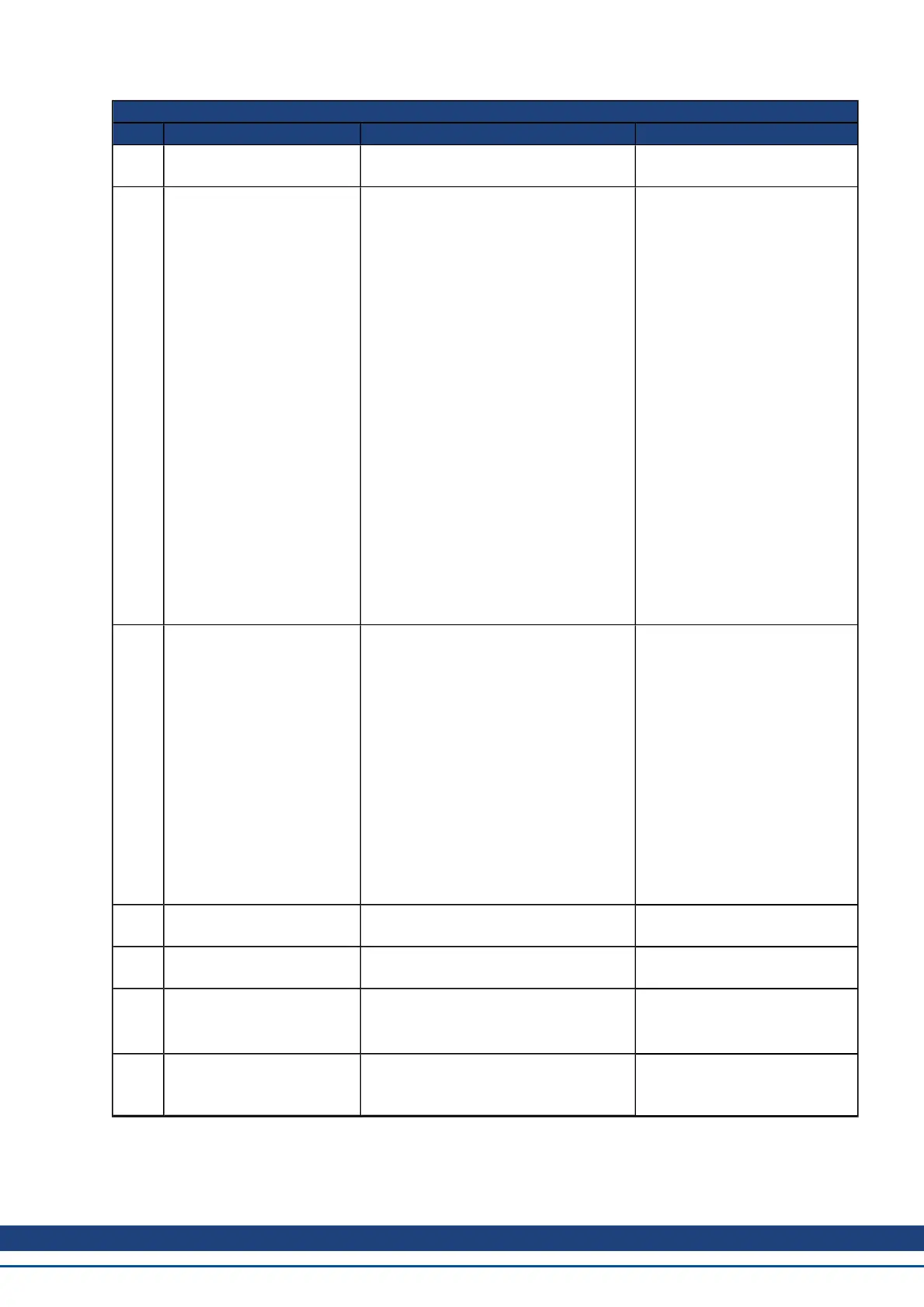

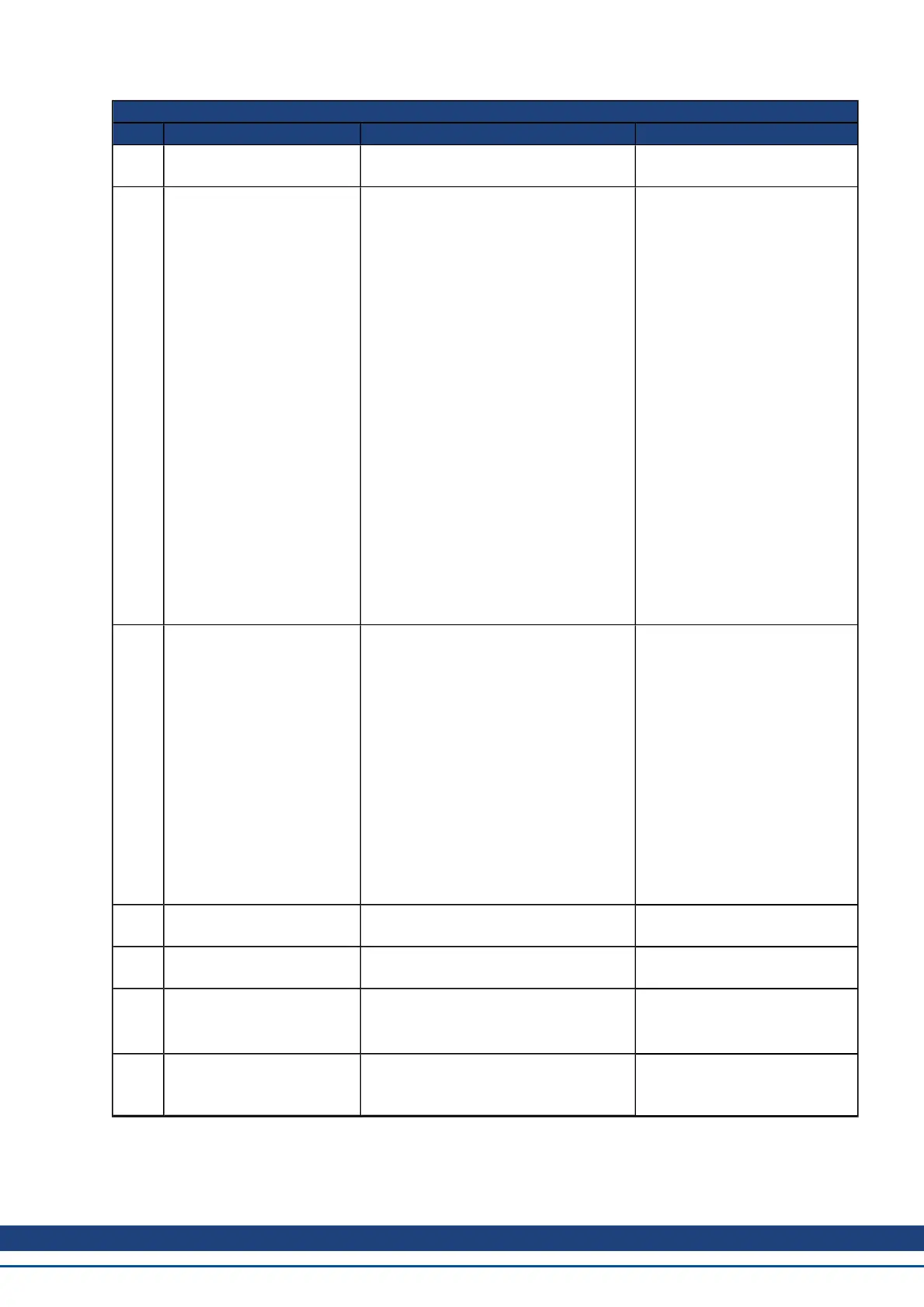

Fault Message/Warning Cause Remedy

531 Power stage fault. Hardware failure detected. Restart drive. If issue persists,

replace drive.

532 Drive motor parameters

setup incomplete.

Before a motor can be enabled, you

must configure a minimum set of param-

eters. These parameters have not been

configured.

Issue the command DRV.S-

ETUPREQLIST to display the

list of the parameters that you

must configure. Configure these

parameters either manually or

automatically. You can manually

configure these parameters in

three ways: (1) set each param-

eter individually; (2) use the

setup wizard to select the motor;

or (3) select the motor type from

the motor data base in the Motor

window (MOTOR.AUTOSET

must be set to 0 (FALSE)). If

you use the Motor window, you

must first select the feedback

type. If the motor has Biss

Analog, Endat, or SFD feedback

(feedback with memory), then

these parameters are set auto-

matically when MOTOR.A-

UTOSET is set to 1 (TRUE).

534 Failed to read motor param-

eters from feedback device.

Motor either does not have motor feed-

back memory, or the motor feedback

memory is not programmed properly so

the parameters cannot be read.

Try to read parameters again by

clicking the Disable and Clear

Faults button, or by issuing the

DRV.CLRFAULTS command. If

this attempt is not successful,

then set MOTOR.AUTOSET to

0 (false) and program the param-

eters using the setup wizard or

manually set up the parameters.

If the motor has motor memory

(Biss Analog, Endat, and SFD

motors have motor memory),

return the motor to have the

memory programmed.

602 Safe torque off. Safe torque off function has been trig-

gered.

Reapply supply voltage to STO

if safe to do so.

701 Fieldbus runtime. Runtime communication fault. Check fieldbus connections

(X11), settings, and control unit.

702 Fieldbus communication

lost.

Warning issued prior to fault.

All fieldbus communication was lost. Check fieldbus connections

(X11), settings, and control unit.

703 Emergency timeout

occurred while axis should

disable

Motor did not stop in the timeout defined. Change timeout value, change

stop parameters, improve tun-

ing.

AKD User Guide | 17 Faults and Warnings

Kollmorgen | December 2010 215

Loading...

Loading...