1. Make sure, that the power supply of the processor module is turned off.

CAUTION!

Risk of damaging the PLC modules!

The PLC modules can be damaged by overvoltages and short circuits.

Make sure, that all voltage sources (supply and process voltage) are

switched off before you are beginning with operations at the system.

2. Disconnect the processor module power supply wires (24 VDC or 100-240 VAC) from the

terminal block for power supply.

3. Unplug the terminal block for power supply with a flat-blade screwdriver of the power con-

nector.

4. Loosen all screws of the onboard I/Os.

5. Remove the input simulator by pulling it to the left side.

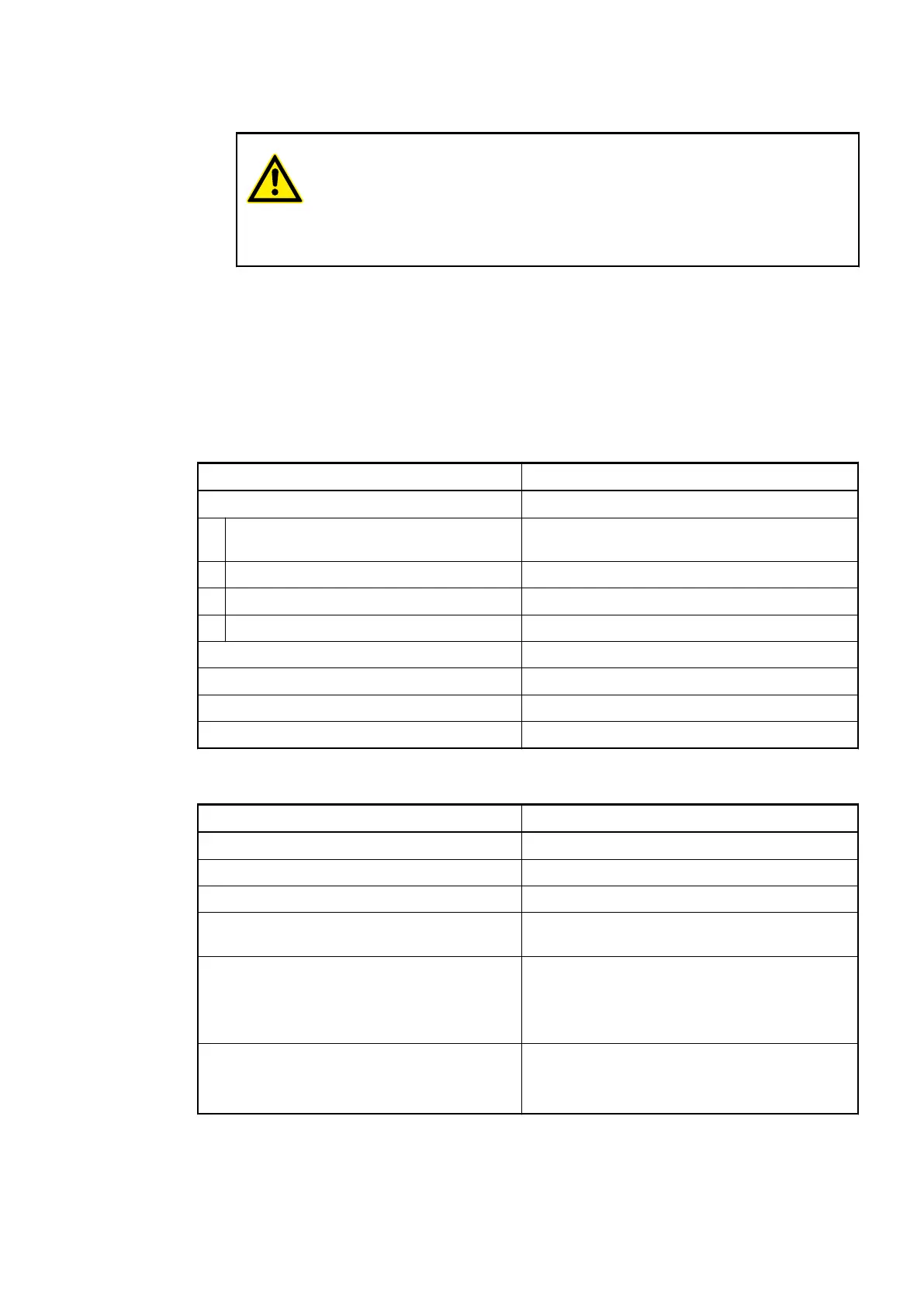

Table 199: Technical Data of the Module

Parameter Value

Process Supply Voltage

Connections Terminal 4 (L+) for +24 VDC and terminal 5 (M)

for 0 VDC

Rated value 24 VDC

Max. ripple 5 %

Protection against reversed voltage Yes

Electrical isolation Yes, per module

Isolated Groups 1 (6 channels per group)

Weight On request

Mounting position Horizontal or vertical

Table 200: Technical Data of the Inputs

Parameter Value

Number of channels per module 6 digital input channels (+24 VDC)

Distribution of the channels into groups 1 (6 channels per group)

Connections of channels DI0 to DI5 Terminals 2...7

Reference potential for the channels DI0 to

DI5

Terminal 1 (minus pole of the process supply

voltage, signal name C0...7)

Input current per active channel (at input

voltage +24 VDC)

The current is given through the used pro-

cessor module.

Typ. 5 mA

Inrush current per active channel

The current is given through the used pro-

cessor module.

Typ. 5 mA

Technical Data

2019/04/173ADR010121, 13, en_US1126

Loading...

Loading...