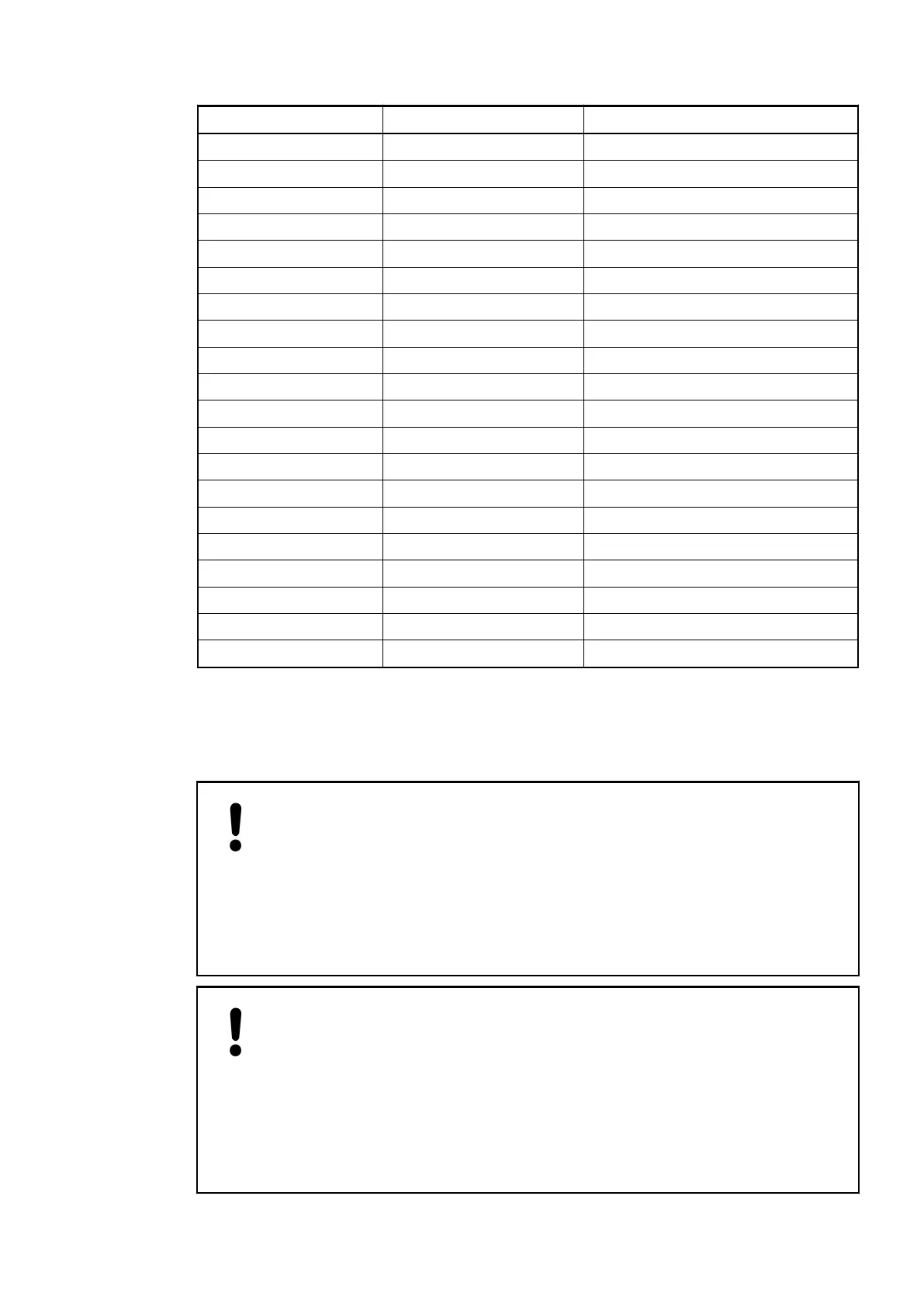

Terminal Signal Description

1 I0+ Plus pole of channel 0

2 I0- Minus pole of channel 0

3 I1+ Plus pole of channel 1

4 I1- Minus pole of channel 1

5 I2+ Plus pole of channel 2

6 I2- Minus pole of channel 2

7 I3+ Plus pole of channel 3

8 I3- Minus pole of channel 3

9 --- Reserved

10 --- Reserved

11 --- Reserved

12 --- Reserved

13 --- Reserved

14 --- Reserved

15 SG Signal ground

16 SG Signal ground

17 SG Signal ground

18 SG Signal ground

19 UP Process voltage UP (24 VDC)

20 ZP Process voltage ZP (0 VDC)

The internal power supply voltage for the module's circuitry is carried out via the I/O bus (pro-

vided by a bus module or a CPU). Thus, the current consumption from 24 VDC power supply at

the terminals UP/L+ and ZP/M of the CPU/bus module increases by 5 mA per AI563.

The external power supply connection is carried out via the UP (+24 VDC) and the ZP (0 VDC)

terminals.

NOTICE!

Risk of imprecise and faulty measurements!

Analog signals may be distorted seriously by external electromagnetic influ-

ences.

Use shielded wires when wiring analog signal sources. The cable shield must

be grounded at both ends of the cable. Provide a potential equalisation of a low

resistance to avoid high potential differences between different parts of the

plant.

NOTICE!

Risk of damaging the PLC modules!

The PLC modules must not be removed while the plant is connected to a power

supply.

Make sure that all voltage sources (supply and process voltage) are switched

off before you

– connect or disconnect any signal or terminal block

– remove or replace a module.

I/O Modules > Analog I/O Modules

2019/04/17 3ADR010121, 13, en_US 419

Loading...

Loading...