8400 HighLine | Parameter setting & configuration

Motor control (MCTRL)

Sensorless vector control (SLVC)

144 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

5.6.4 Remedies for undesired drive behaviour

Drive behaviour Remedy

Deviation between no-load current and magnetising

current or bad speed or torque accuracy.

Adapt the motor magnetising inductance (C00092

) for

no-load operation.

• If the no-load current is greater than the magnetising

current (C00095

) at 0.5-fold rated motor speed, the

magnetising inductance must be reduced until the

no-load current and the magnetising current have the

same values.

• Otherwise, the magnetising inductance must be

increased.

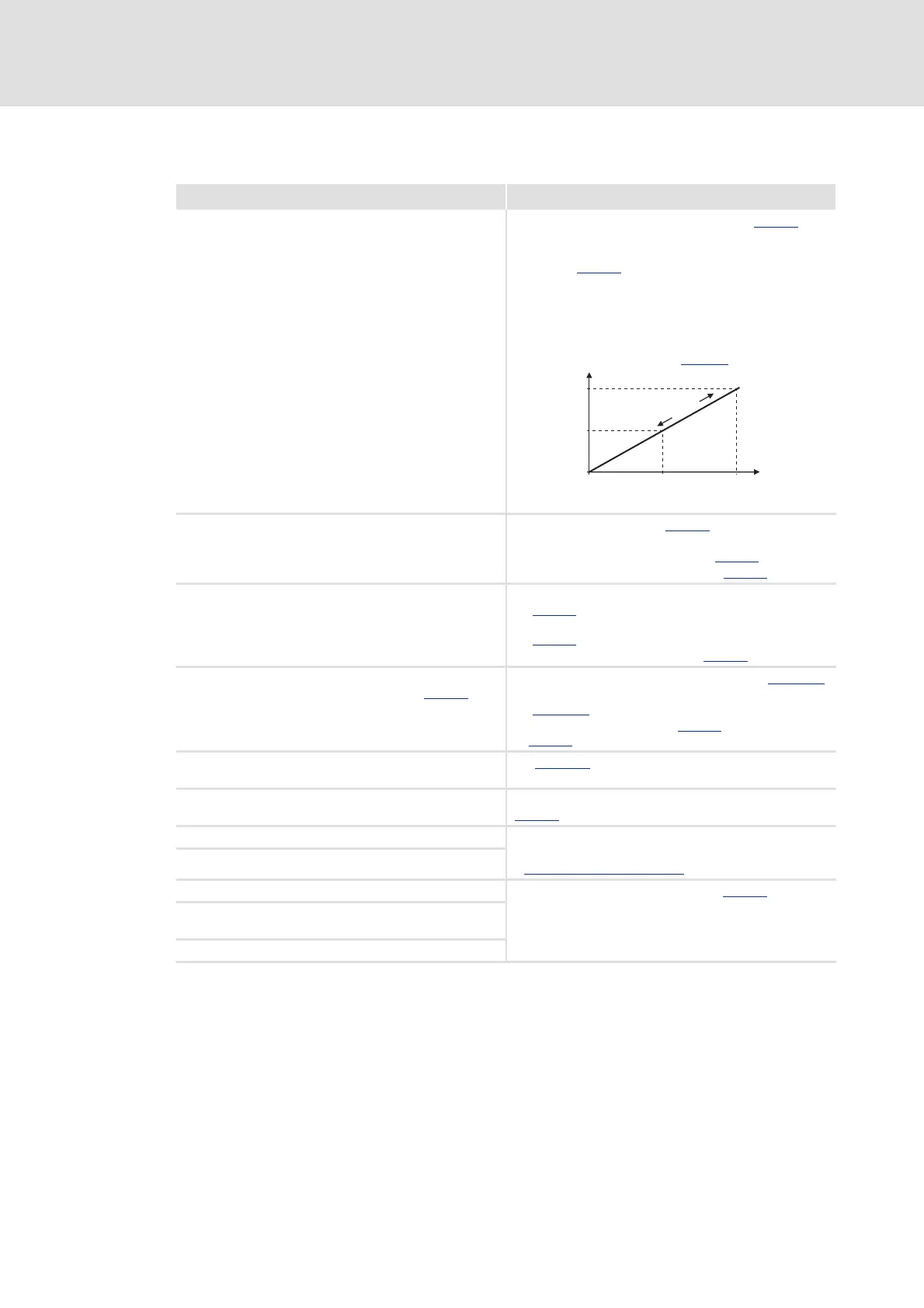

Tendency of the correction of C00092:

PN: Rated motor power

Insufficient speed constancy at high load: Setpoint and

motor speed are not proportional anymore.

Caution: Overcompensation of the settings mentioned

under " Remedy" may result in unstable behaviour!

Via the slip compensation (C00021

), the speed stability

under high loads can be affected:

•If n

act

> n

slip

, reduce the value in C00021

•If n

act

< n

slip

, increase the value in C00021

Unstable control with higher speeds. • Check the setting of the magnetising inductance

(C00092

) by comparing the current consumption in

no-load operation with the rated magnetising current

(C00095

).

• Optimise oscillation damping (C00234

).

"Short circuit" (OC1) or "Clamp operation active" (OC11)

error messages at short acceleration time (C00012

) in

proportion to the load (controller cannot follow the

dynamic processes).

• Increase the gain of the torque controller (C00073/2

).

• Reduce the reset time of the torque controller

(C00074/2

).

• Increase the acceleration (C00012

)/deceleration (

C00013

) time.

Mechanical resonance at certain speeds. The L_NSet_1

function block masks out those speed

ranges that include resonance.

Speed variations in no-load operation for speeds > 1/3

rated speed.

Minimise speed oscillations with oscillation damping

(C00234

).

Drive runs unstable. Check set motor data (nameplate data and equivalent

circuit diagram data).

Motor selection/Motor data

( 97)

Setpoint speed and actual speed differ strongly.

The torque required is not generated at standstill. Increase motor magnetising current (C00095).

Current overshoots occur when heavy loads are

accelerated from standstill (OC1 or OC11 error).

The machine runs uneven.

0,37

22

90

C0092

-15 %

+15 %

0

P [kW]

N

efesotomasyon.com - Lenze

Loading...

Loading...