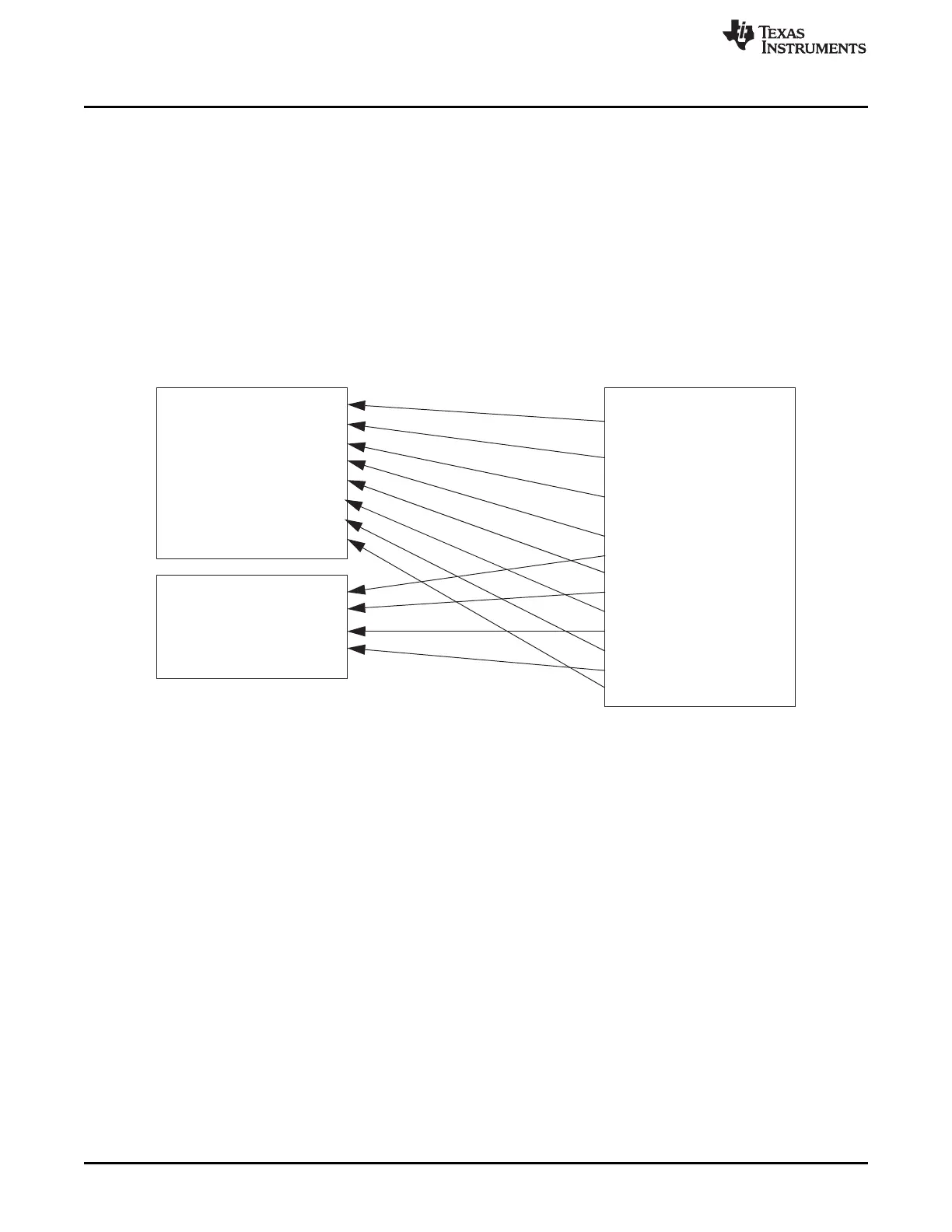

HTU

DCP[0]

DCP[1]

DCP[2]

DCP[3]

DCP[4]

DCP[5]

DCP[6]

DCP[7]

DMA

DMAREQ[20]

DMAREQ[21]

DMAREQ[24]

DMAREQ[25]

N2HET

DMAREQ[0]

HTUREQ[0]

DMAREQ[1]

HTUREQ[1]

DMAREQ[2]

HTUREQ[2]

DMAREQ[3]

HTUREQ[3]

DMAREQ[4]

HTUREQ[4]

DMAREQ[5]

HTUREQ[5]

DMAREQ[6]

HTUREQ[6]

DMAREQ[7]

HTUREQ[7]

N2HET Functional Description

www.ti.com

990

SPNU563A–March 2018

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

High-End Timer (N2HET) Module

23.2.9 N2HET Requests to DMA and HTU

As described in Section 23.6.3, the majority of the N2HET instructions are able to generate a transfer

request to the High-End Timer Transfer Unit (HTU) and/or to the DMA module when an instruction-specific

condition is true. One N2HET instruction can select one of 8 request lines by programming the “reqnum”

parameter. The “request” field in an instruction is used to enable, disable, or to generate a quiet request

(see Section 23.6.2) on the selected request line. Quiet requests can be used by the HTU, but not by the

DMA. For quiet request, refer to the High-End Timer Transfer Unit (HTU) Module chapter (see

Section 24.2.4.1).

The configuration of the N2HET Request Destination Select Register (HETREQDS) bits determines if a

request line triggers an HTU-DCP, a DMA channel or both. This means the register bits will determine

whether an N2HET instruction triggers DMAREQ[x], HTUREQ[x] or both signals (shown in Figure 23-29).

The request line number x corresponds to the “reqnum” parameter used in the instruction.

Figure 23-29. Request Line Assignment Example

23.3 Angle Functions

Engine management systems require an angle-referenced time base to synchronize signals to the engine

toothed wheel. The N2HET has a method to provide such a time base for low-end engine systems. The

reference is created by the N2HET using three dedicated instructions with fractional angle steps equal to

/8, /16, /32, /64.

23.3.1 Software Angle Generator

The N2HET provides three specialized count instructions to generate an angle referenced time base

synchronized to an external reference signal (the toothed wheel signal) that defines angular reference

points.

The time base is used to generate fractional angle steps between the reference points. The step width K

(= 8, 16, 32, or 64) programmed by the user defines the angle accuracy of the time base. These fractional

steps are then accumulated in an angle counter to form the absolute angle value.

The first counter, APCNT, incremented on each loop resolution clock measures the periods P(n) of the

external signal. The second counter SCNT counts by step K up to the previous period value P(n-1),

measured by APCNT, and then recycles. The resulting period of SCNT is the fraction P(n-1) / K. The third

counter ACNT accumulates the fractions generated by SCNT.

Figure 23-30 illustrates the basic operation of APCNT, SCNT, and ACNT.

A N2HET timer program can only have one angle generator.

Loading...

Loading...