January 2007

6-25

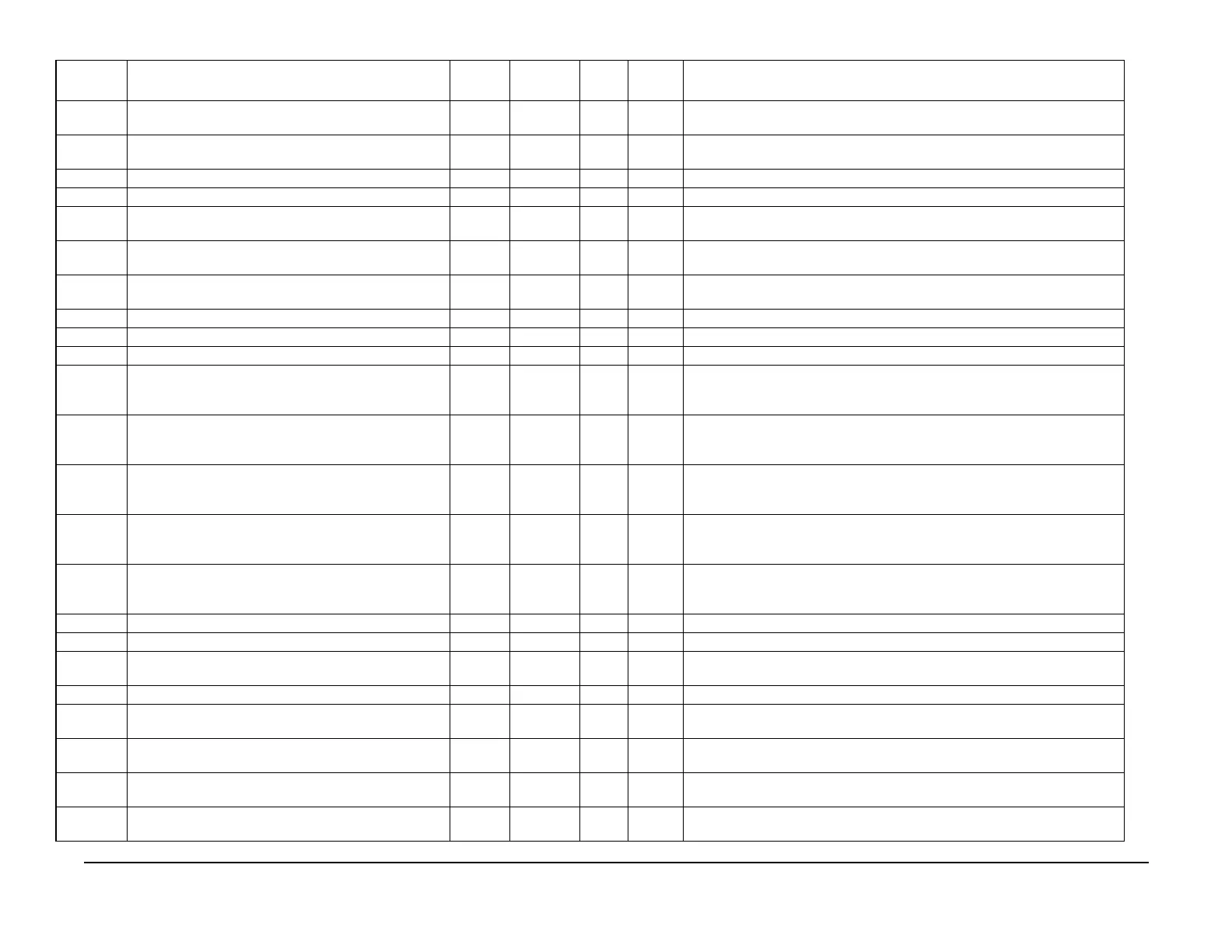

WorkCentre 7132

IOT NVM List

General procedures information

Reversion 4.0

742-273 Timing of Finishing Countermeasure Ope against Con-

densation (full speed)

14 0~50 100ms RW Timing of stopping Exit 2 Motor after Exit Sensor 1Off (full speed)

742-274 Timing of Finishing Countermeasure Ope against Con-

densation (half speed)

27 0~50 100ms RW Timing of stopping Exit 2 Motor after Exit Sensor 1Off (half speed)

742-281 MSI-Feed Paper Qty 0 0~1500000 R It is time to replace the periodic replacement part: TA Roll

742-282 Tray 1- Feed Paper Qty 0 0~1500000 R It is time to replace the periodic replacement part: TA Roll

742-283 Tray 2-Feed Paper Qty 0 0~600000 R It is time to replace periodic replacement parts:

Nudger/Feed/Retard Roll

742-284 Tray 3-Feed Paper Qty 0 0~600000 R It is time to replace periodic replacement parts:

Nudger/Feed/Retard Roll

742-285 Qty of Tray 1 Lifter Adjustments 0 0~100 R Counts Tray 1 Lifter adjustments. Every time Lifter is adjusted after it lifts up, 1

is added. (for reference)

742-286 Tray 1 Lift Up Time 0 0~3000 R Stores Tray 1 Lift Up time. (for reference)

742-287 Tray 2 Lift Up Time 0 0~15000 R Stores Tray 2 Lift Up time. (for reference)

742-288 Tray 3 Lift Up Time 0 0~15000 R Stores Tray 3 Lift Up time. (for reference)

742-289 Count Coefficient for Remaining Paper Qty Detection

(Tray 1)

(Remaining Qty Correction Time in adjusting Lifter)

30 0~100 1ms RW Coefficient for detecting and calculating what quantity of paper remains in Tray

1. (time taken to adjust Lifter)

742-290 Count Coefficient for Remaining Paper Qty Detection

(2TM-Tray 2)

(Remaining Qty Correction Time in adjusting Lifter)

30 0~100 1ms RW Coefficient for detecting and calculating what quantity of paper remains in 500-

sheet Tray. (time taken to adjust Lifter)

742-291 Count Coefficient for Remaining Paper Qty Detection

(2TM-Tray 3)

(Remaining Qty Correction Time in adjusting Lifter)

30 0~100 1ms RW Coefficient for detecting and calculating what quantity of paper remains in 500-

sheet Tray. (time taken to adjust Lifter)

742-292 Count Coefficient for Remaining Paper Qty Detection

(TTM-Tray 2)

(Remaining Qty Correction Time in adjusting Lifter)

34 0~100 1ms RW Coefficient for detecting and calculating what quantity of paper remains in TTM

Tray 2. (time taken to adjust Lifter)

742-293 Count Coefficient for Remaining Paper Qty Detection

(TTM-Tray 3)

(Remaining Qty Correction Time in adjusting Lifter)

34 0~100 1ms RW Coefficient for detecting and calculating what quantity of paper remains in TTM

Tray 3. (time taken to adjust Lifter)

742-294 MSI Size Guide minimum position 963 904~1023 RW Stores min. data in correcting Size Sensor.

742-295 MSI Size Guide maximum position 194 0~258 RW Stores max. data in correcting Size Sensor.

742-301 OHP Sensor PWM default value (at Power On) 1000 0~1000 0.1% RW Default to execute auxiliary operation that controls variations in OHP Sensor.

(used with Power On)

742-302 OHP Sensor Correction Operation standard value 1000 0~1000 0.1% RW Default to execute auxiliary operation that controls variations in OHP Sensor

742-303 OHP Sensor target value 155 60~330 1 RW Adjusts threshold to correct OHP PWM output value in OHP correction opera-

tion.

742-304 Sampling Qty (in OHP correction operation) 2 1~5 2 RW Adjusts how many samples of OHP Sensor Value to take in OHP correction

operation.

742-305 Sampling Qty (detection of paper type) 10 1~20 1 RW Adjusts how many samples of OHP Sensor Value to take in detecting paper

type.

742-306 Delay in sampling (in OHP correction operation) 3 1~10 1ms RW Adjusts how long to delay sampling OHP Sensor value after PWM output in

OHP correction operation.

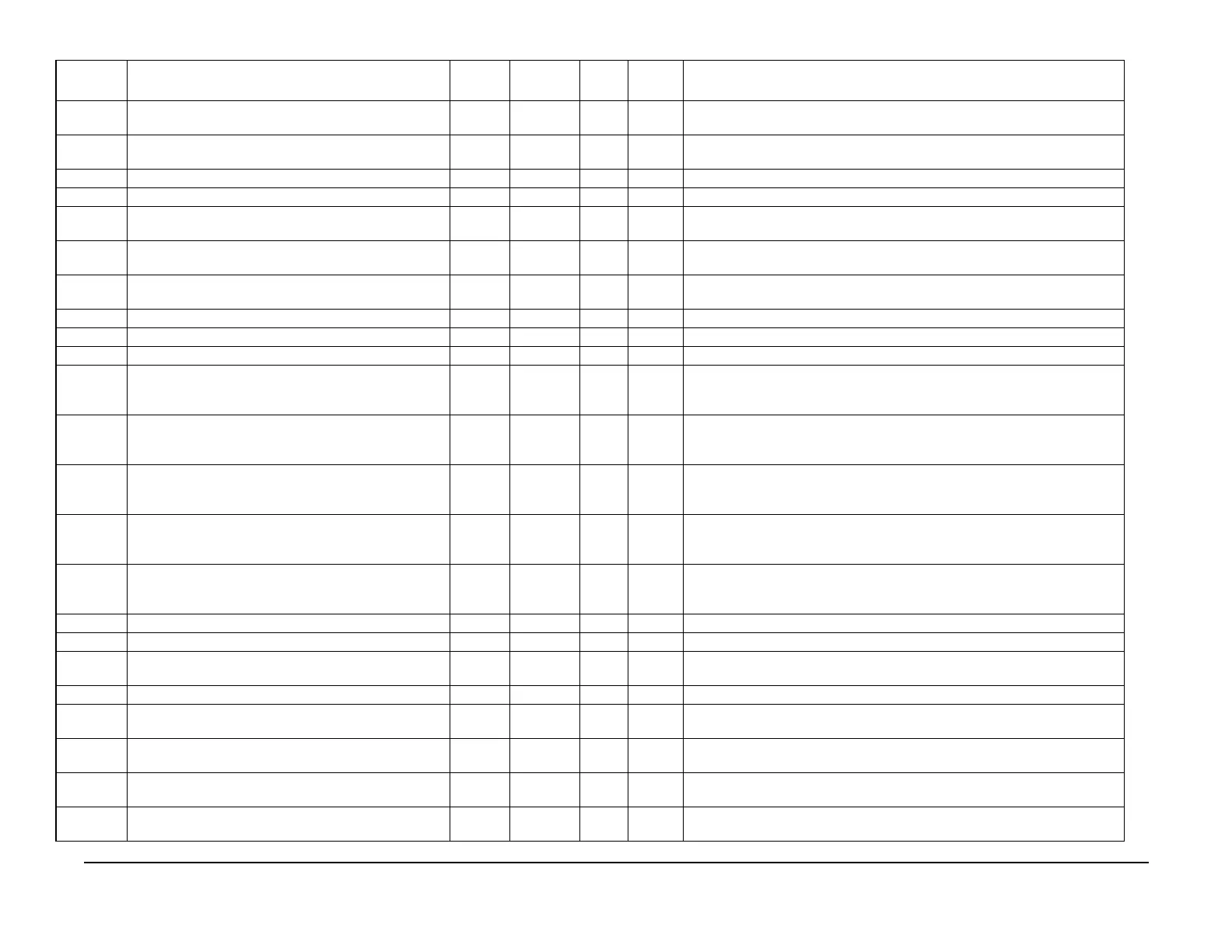

Table 3 Paper Handling

Chain-Link Name Default Range

Step

(mm)

Read/

Write Description

Loading...

Loading...