January 2007

6-193

WorkCentre 7132

Component Control

General procedures information

Reversion 4.0

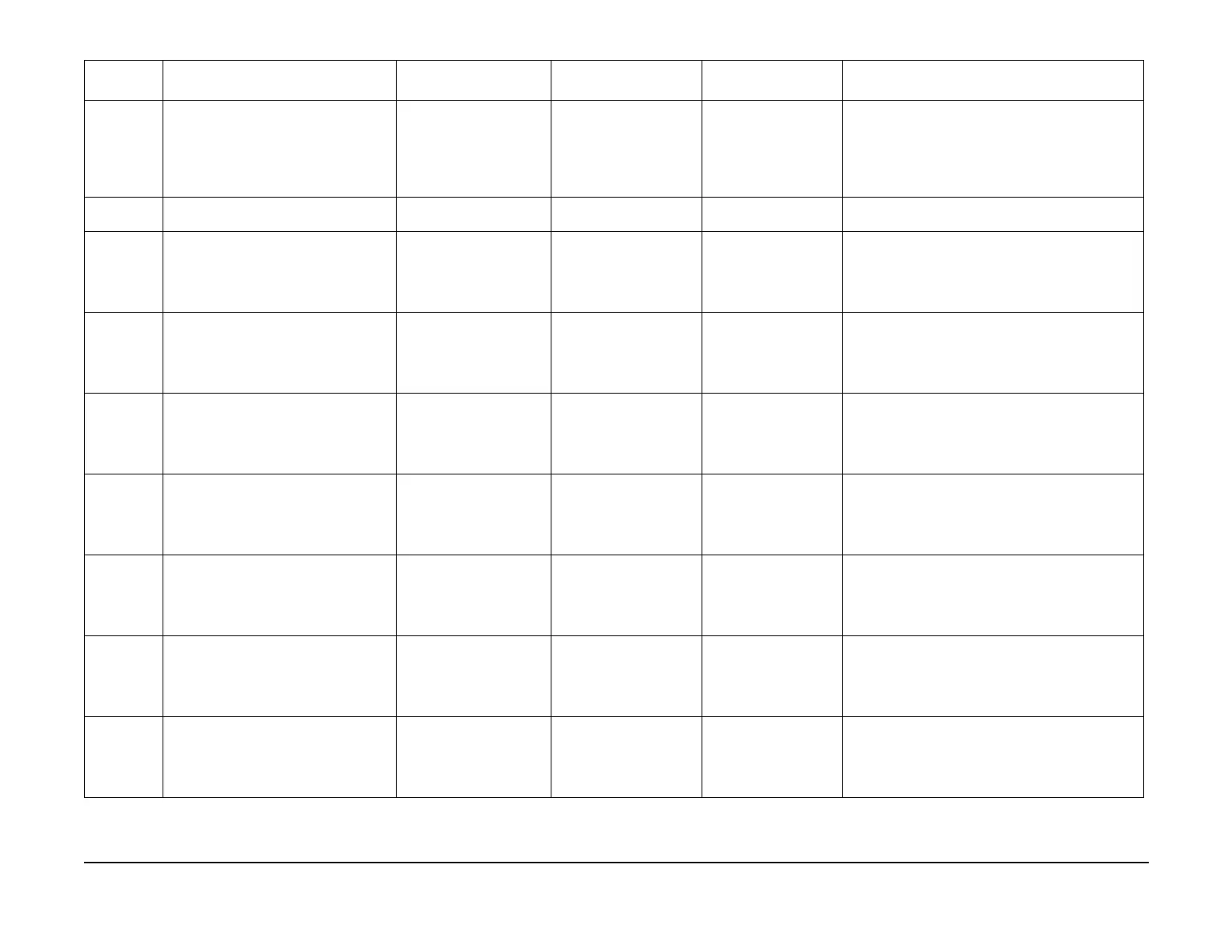

012-014 Sub Paddle Rotation equal to 012-13 and 012-

95

Sub Paddle makes one

rotation.

(Rotates Transport Motor

FORWARD at the same

time as Sub Paddle Sole

-

noid turns ON.)

Mot: 3162

Pulse Sol: 660ms

012-013

012-095

012-096

012-097

012-017 Set Clamp Motor ON/OFF Pulse: ON

H: OFF

Set Clamp Motor rotates

forward.

250 pulses 012-061

012-020 Front Tamper Mot Low FRONT ON/OFF Pulse: ON

H: OFF

Front Tamper moves to

Front at low speed.

100 pulses 012-021

012-022

012-023

012-024

012-025

012-021 Front Tamper Mot Middle FRONT ON/

OFF

Pulse: ON

H: OFF

Front Tamper moves to

Front at medium speed.

100 pulses 012-020

012-022

012-023

012-024

012-025

012-022 Front Tamper Mot High FRONT ON/OFF Pulse: ON

H: OFF

Front Tamper moves to

Front at high speed.

100 pulses 012-020

012-021

012-023

012-024

012-025

012-023 Front Tamper Mot Low REAR ON/OFF Pulse: ON

H: OFF

Front Tamper moves to

Rear at low speed.

100 pulses 012-020

012-021

012-022

012-024

012-025

012-024 Front Tamper Mot Middle REAR ON/OFF Pulse: ON

H: OFF

Front Tamper moves to

Rear at medium speed.

100 pulses 012-020

012-021

012-022

012-023

012-025

012-025 Front Tamper Mot High REAR ON/OFF Pulse: ON

H: OFF

Front Tamper moves to

Rear at high speed.

100 pulses 012-020

012-021

012-022

012-023

012-024

012-026 Rear Tamper Mot Low FRONT ON/OFF Pulse: ON

H: OFF

Rear Tamper moves to

Front at low speed.

100 pulses 012-027

012-028

012-029

012-030

012-031

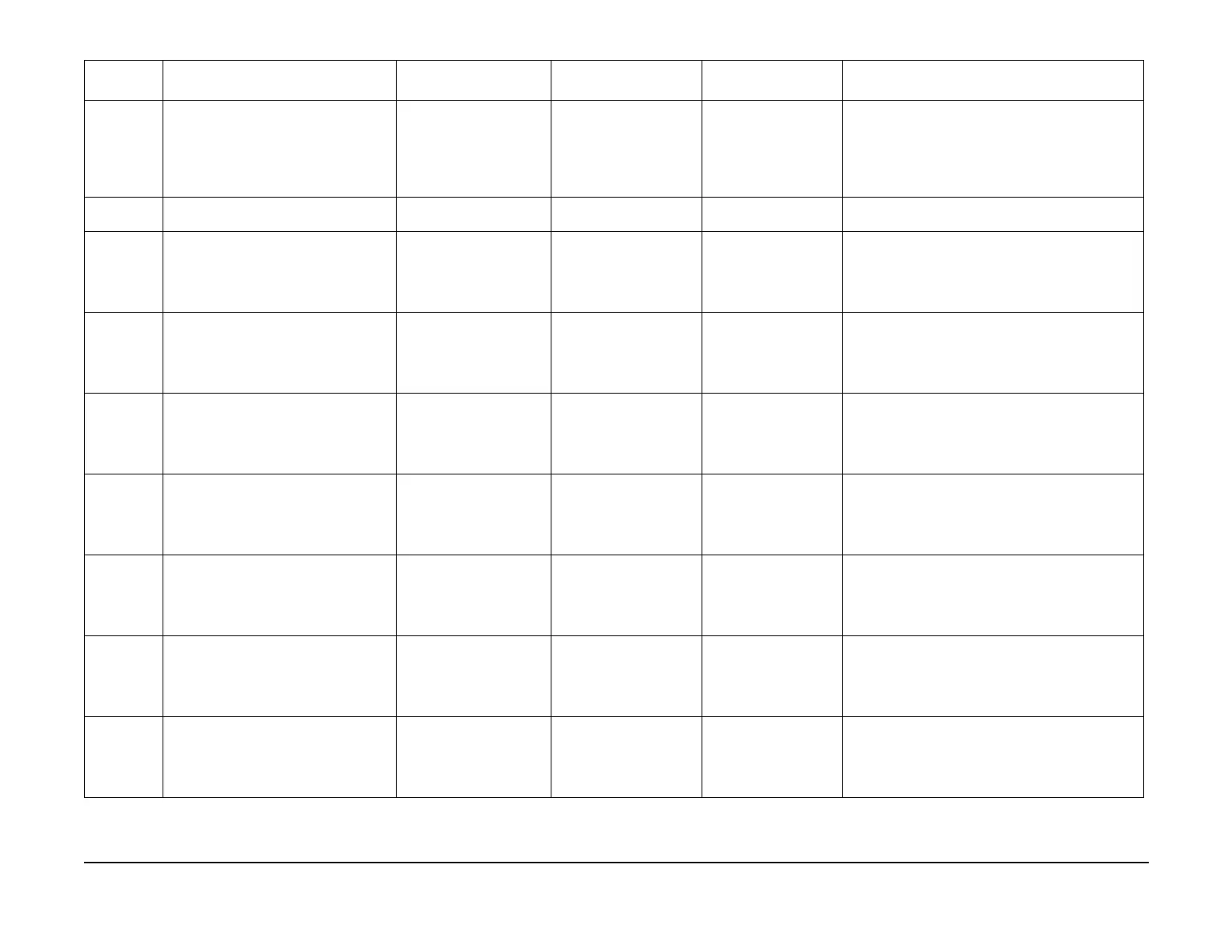

Table 6 Output Component Control Codes A-Finisher

Chain-Link Name Connector Meaning Time Off

Multiple Output

Prohibited Items

Loading...

Loading...