Shape Search III

184

FH/FZ5 Processing Item Function Reference Manual

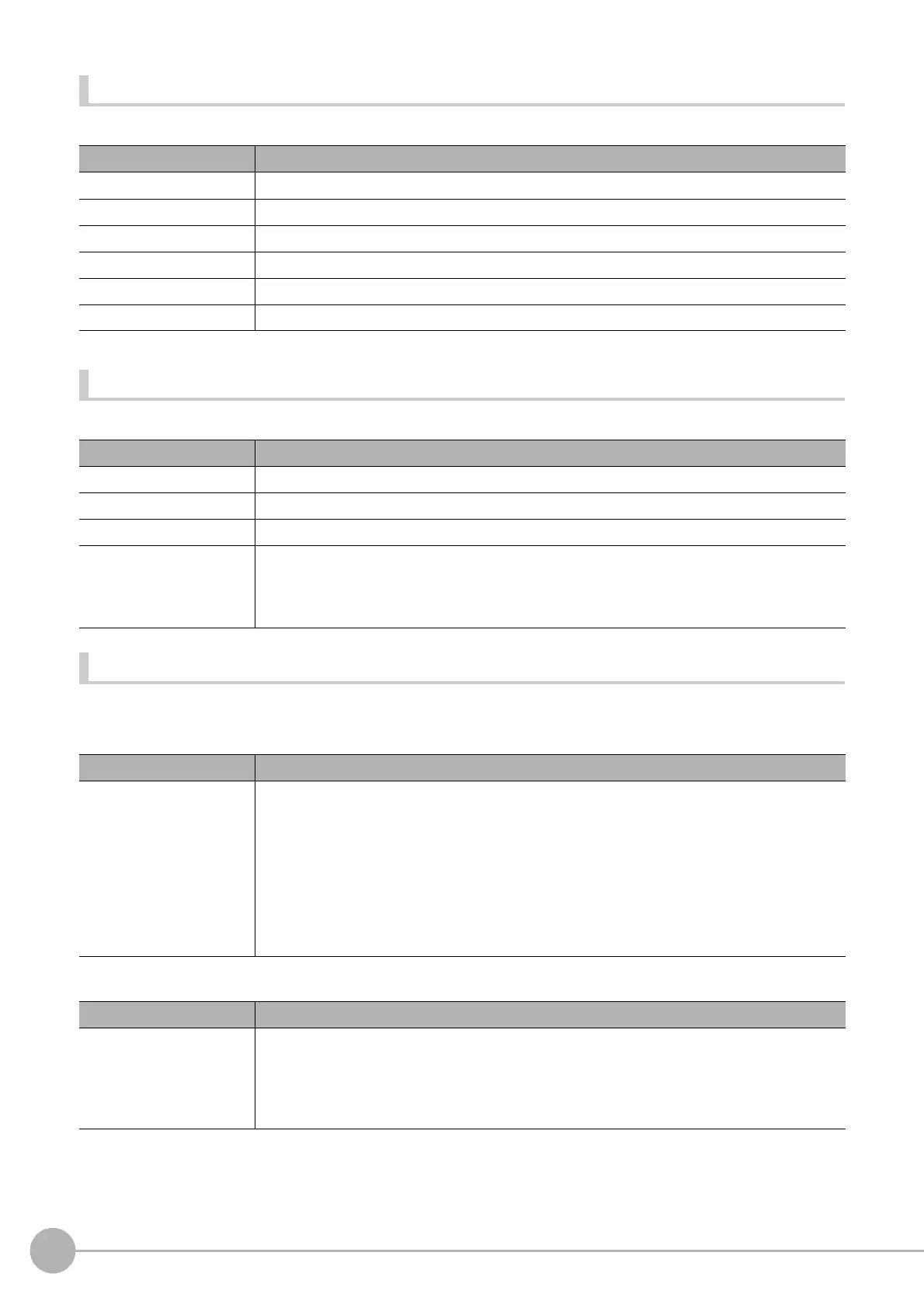

Content displayed in the Detail result area

The following measurement results are displayed in the Detail result area as text.

Displayed contents in the Image display area

The following images are displayed with set the Sub image number in the Image display area.

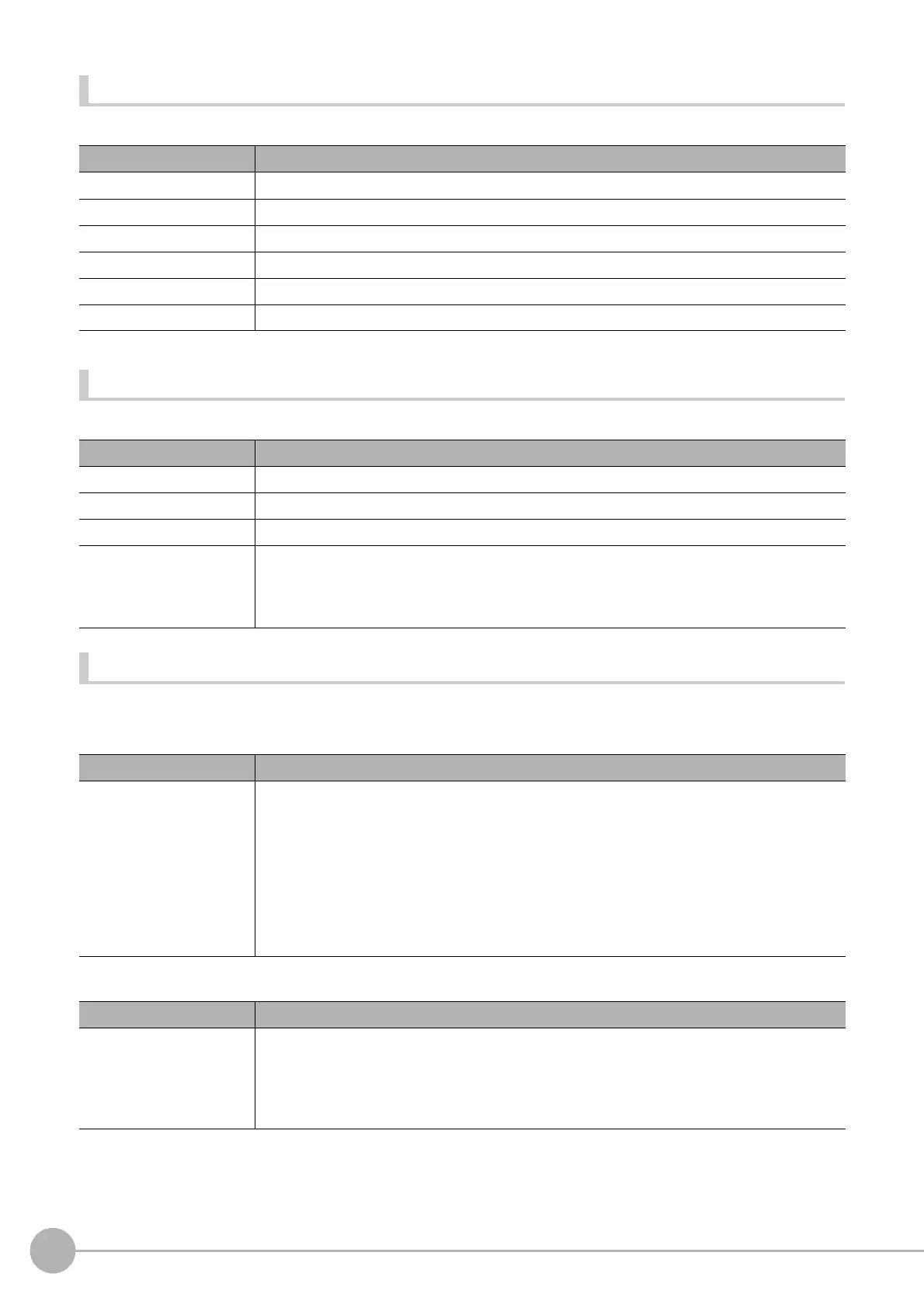

For adjustment of measurement accuracy or uneven

There are the following methods to adjust the measurement accuracy or uneven.

When the measurement results are unstable.

In the case of searching other position

Displayed Items Description

Judge Judgement result

Count Number of detections

Correlation Correlation value

Position X X coordinate of the position wh

ere th

e model is detected.

Position Y Y coordinate of the position where th

e model is detected.

Angle θ Angle of the position where the model is detected.

Sub image number Description

0 Measurement image

1 Measurement image with detection results overlaid.

2 Edge image

3

Edge image with detection results overlaid.

Green: Matched model points

Yellow: Model points matched but with different directions

Red: Unmatched model points

Parameter to be adjusted Troubleshooting

Measurement parameter

Reference: Measurement

parameter (Shape Search

III) (p.179)

• If the variability for good workpieces is large.

Decrease [Candidate LV].

• If there are large differences in the shape of individual workpieces.

Raise [Acceptable distortion level], if th

e co

rrelating value is decreased

when you change the work Piece.

• Except for the work pieces shape can be detected.

Raise [Edge Level], if work’

s

dirty point or fine patterns are miss-detected.

• It could be not able to measure in pixel unit.

Check [High-Prec.], if the accuracy of

mea

surement coordinates is low.

Parameter to be adjusted Troubleshooting

Measurement parameter

Reference: Measurement

parameter (Shape Search

III) (p.179)

• Detected target can be found too much.

Raise [Acceptable distortion level] if miss-detected is occurred

,

e.g. place where is

no work piece or similar to wo

rk piece shape are detected.

• Miss-detection can be occurred because there are many edges back on work pie

ces

P target edges are not able to be detected.

Loading...

Loading...