DefectFH/FZ5 Processing Item Function Reference Manual

361

2

Inspecting and Measuring

Measurement Parameters (Defect)

This item specifies the judgement condition for measurement results. Measurement parameters can be changed

as needed to address unstable measurement results or to increase the processing speed.

1 In the Item Tab area, click [Measurement].

2 Set the value of each item in the "Defect

size" area.

3 If necessary, set the value of each item in the "Measurement parameter" area.

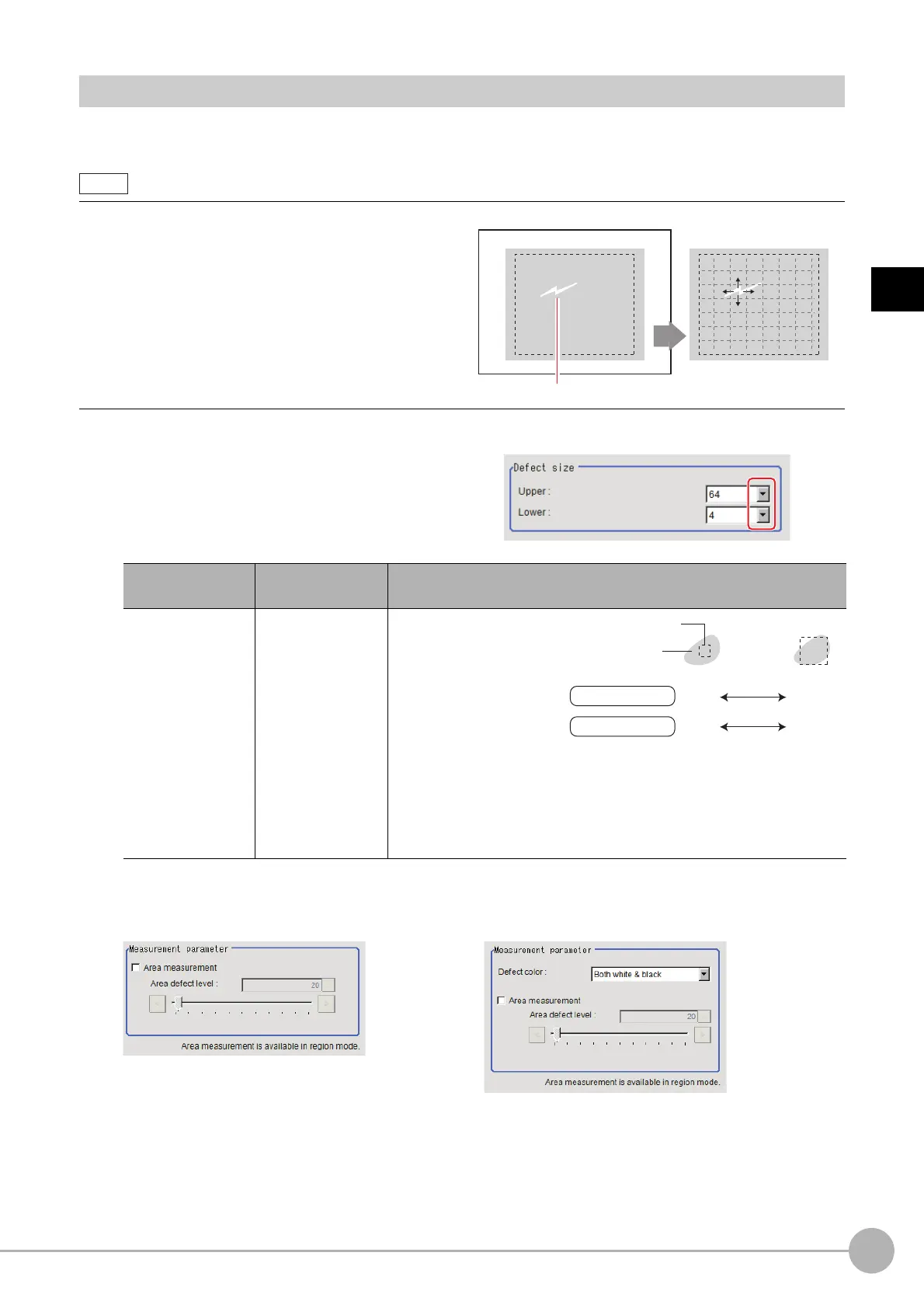

Defect detection mechanism

• After measurement region is drawn, a rectangle (defect

dete

ction region) is automatically formed in this region.

While moving the defect detection region around,

calculate the RGB color averages at each location and

find the defect detection difference with surrounding

defects. This difference is called the defect level.

Calculate the defect level for all defect detection areas. If

the maximum value exceeds the judgement value, it is

judged that there are defects in the measurement region.

Setting item

Set value

[Factory default]

Description

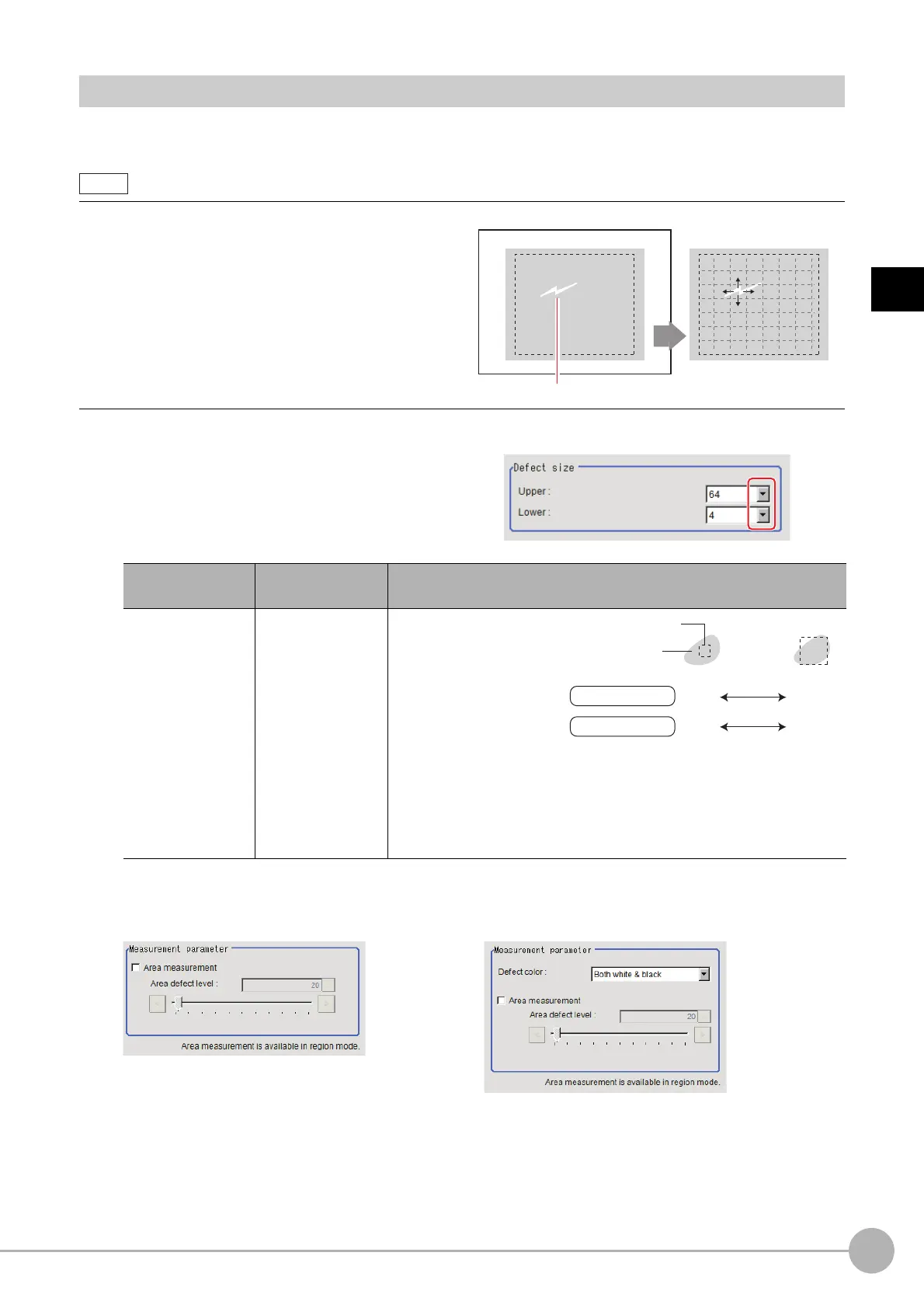

Defect size

•4

•8

•12

•16

•24

•32

•64

[4] to [64]

Specify the upper and

lowe

r li

mits of defect

detection size based on

the size of scratch or

contamination to be

detected. A defect

detection region is

automatically created

with the number of pixels for the defects size.

The larger the difference between upper and lower limits, the easier to

detect

d

efects/contamination of various sizes.

For both upper and lower limits, higher values for defect detection size

limit

s

leads to weaker detection sensitivity and shorter processing time.

For color cameras: For monochrome cameras:

Defect detection region

Defect

Sensitivity high low

Defect detection

size

Defect

Processing Time

long short

Loading...

Loading...