Glue Bead Inspection

500

FH/FZ5 Processing Item Function Reference Manual

6 If necessary, set the following parameters in the "Model parameter" area.

7 If necessary, set up display settings for the images in the "Display setting" area.

Measurement Parameters (Glue Bead Inspection)

Set the inspection measurement conditions and the judgement conditions for the measurement results.

1 In the Item Tab area, click [Measurement].

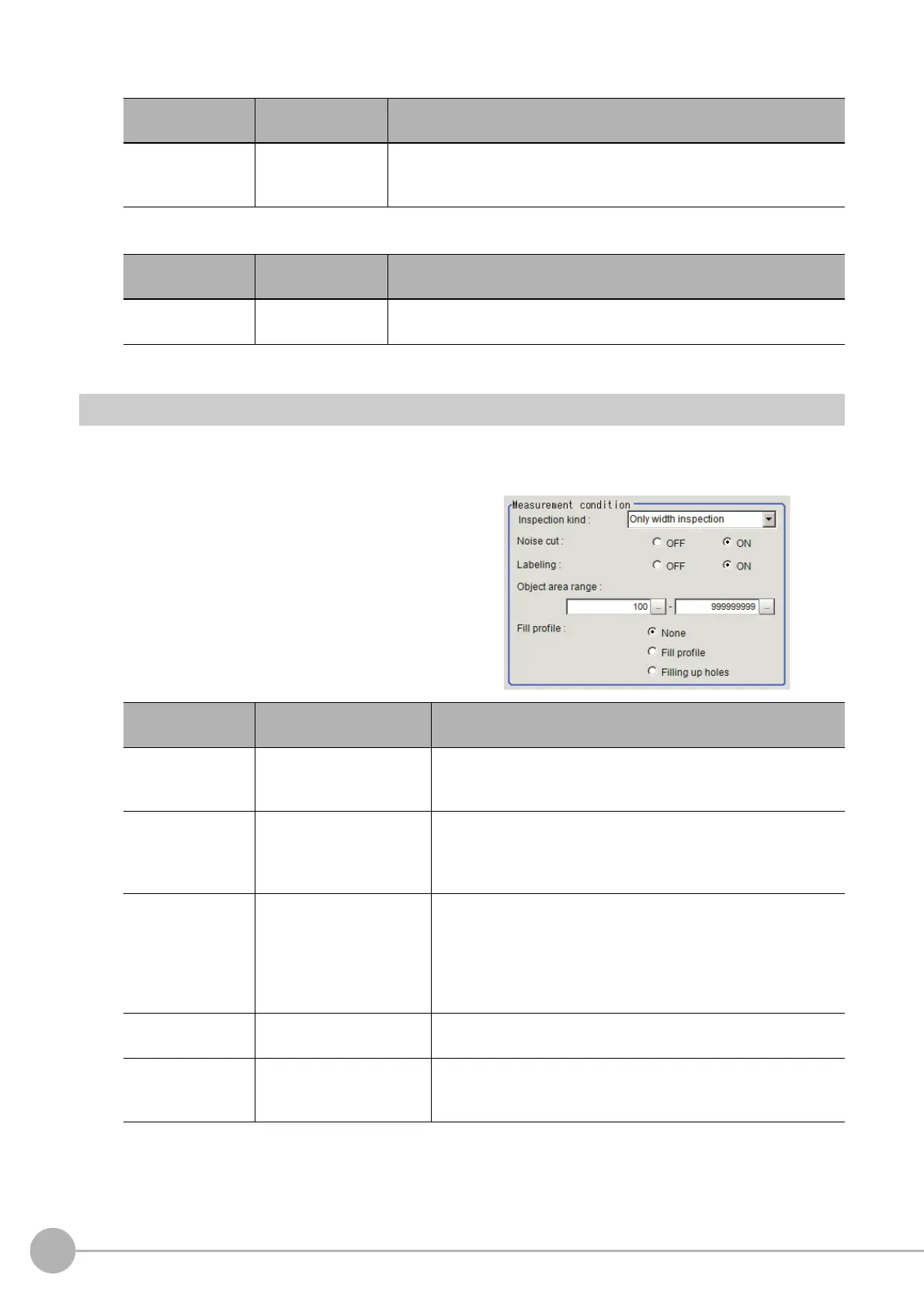

2 In the "Measurement condition" area,

specify a value for each item.

Setting item

Setting value

[Factory default]

Description

Route limit width

2 to 100

[10]

Specify a glueing route width to be judged

as "OK". When it exceeds the

set area the inspection result will be "NG".

The unit is pixel.

Setting item

Setting value

[Factory default]

Description

Binary image

• [Checked]

• Unchecked

When checked, the binary image is displayed.

Setting item

Setting value

[Factory default]

Description

Inspection kind

• [Only width inspection]

• Only route inspection

• Both inspection

Select the inspection type.

Noise cut

•OFF

•[ON]

Select whether or not to process noise removal.

Set this option if fine pixel noises generate.

Basically the processing should be set to "ON" to ensure stable

mea

s

urement.

Labeling

•OFF

•[ON]

Select whether or not to process noise removal using the labeling

filter

.

Set th

is option if noises generate.

You can use this processing to measure only the labels in the

ran

ge set in "Object area range ". Basically the processing should

be set to "ON" to ensure stable measurement.

Object area range

0 to 99999999

[100 to 99999999]

Set the area range of labels to be measured.

Fill profile

• [None]

• Fill profile

• Filling up holes

Select the fill profile method.

You can use the Fill profile setting item when the Labeling setting

item is s

e

t to ON.

Loading...

Loading...