PLC Master CalibrationFH/FZ5 Processing Item Function Reference Manual

769

4

Support Inspection and Measurement

Machine Setting (PLC Master Calibration)

Select a processing item (stage data or robot data) under which external device information needed for

calculation of axis movement amount is held.

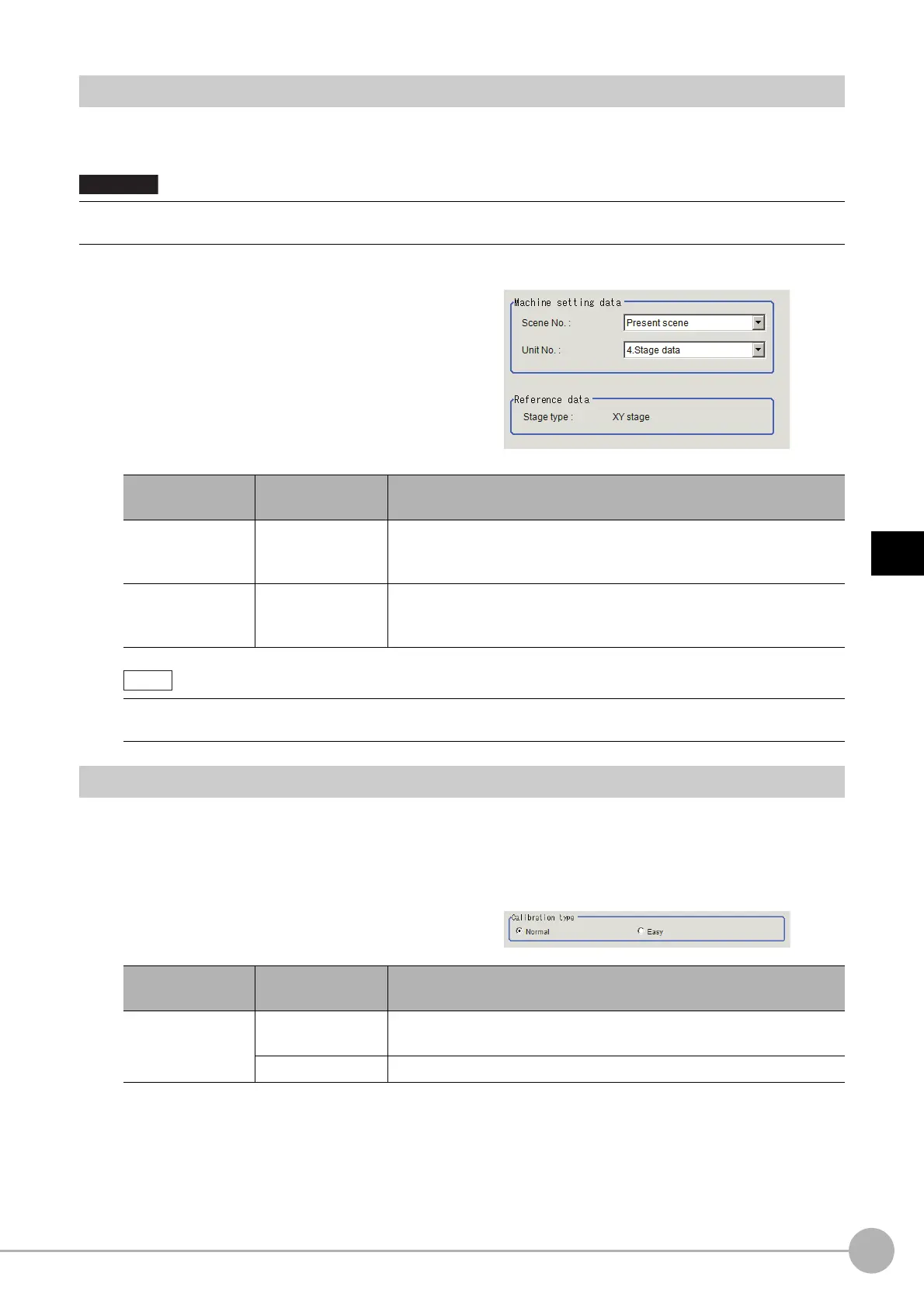

1 In the Item Tab area, click [Machine setting].

2 Select the processing unit that retains

information on external device.

Information of the selected processing unit is

displayed in the reference data display area.

Displayed contents may change depending on

sele

cte

d type of Robot or Stage.

Calibration (PLC Master Calibration)

This item sets data related to calibration. Sets the number of calibration data to be created and the measurement

processing items to be used for sampling in the arithmetic expression. Also sets the output method for the

calculated axis movement amount.

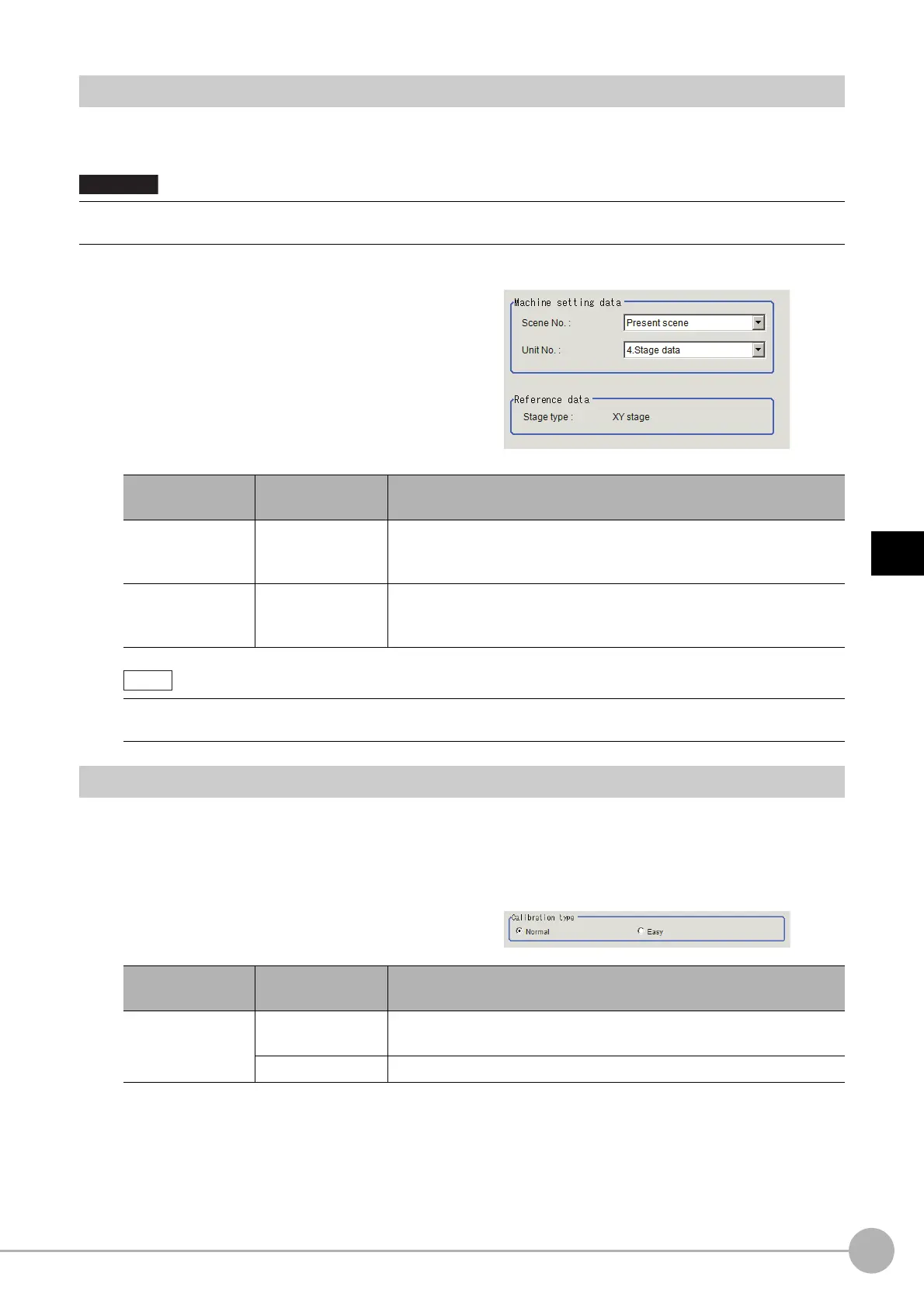

1 In the Item Tab area, click [Calibration].

2 Select the calibration method in the

"Calibration type" area.

• [PLC Master Calibration] refers to [Stage Data] or [Robot Data]. Be sure to register [Stage Data] or [Robot Data] with a

given scene.

Setting item

Setting value

[Factory default]

Description

Scene No.

[Present scene]

Scenes 0 to 127

Select a scene number (stage data or robot data) under which external

device i

nformation needed for calculation of axis movement amount is

held.

Unit No. ---

From among the referenced scene numbers, select a processing item

(stage data or robot data) under which external device information

needed for calculation of axis movement amount is held.

• If the number of scenes is increased using the scene g

r

oup conversion tool, the maximum value that can be

selected in "Scene No." changes.

Setting item

Setting value

[Factory default]

Description

Calibration type

[Normal]

Perform calibration by combining the "measurement command" and "set

unit dat

a command" from the control equipment (PLC).

Easy Perform calibration by using the "measurement command" only.

Loading...

Loading...