Fine Matching

382

FH/FZ5 Processing Item Function Reference Manual

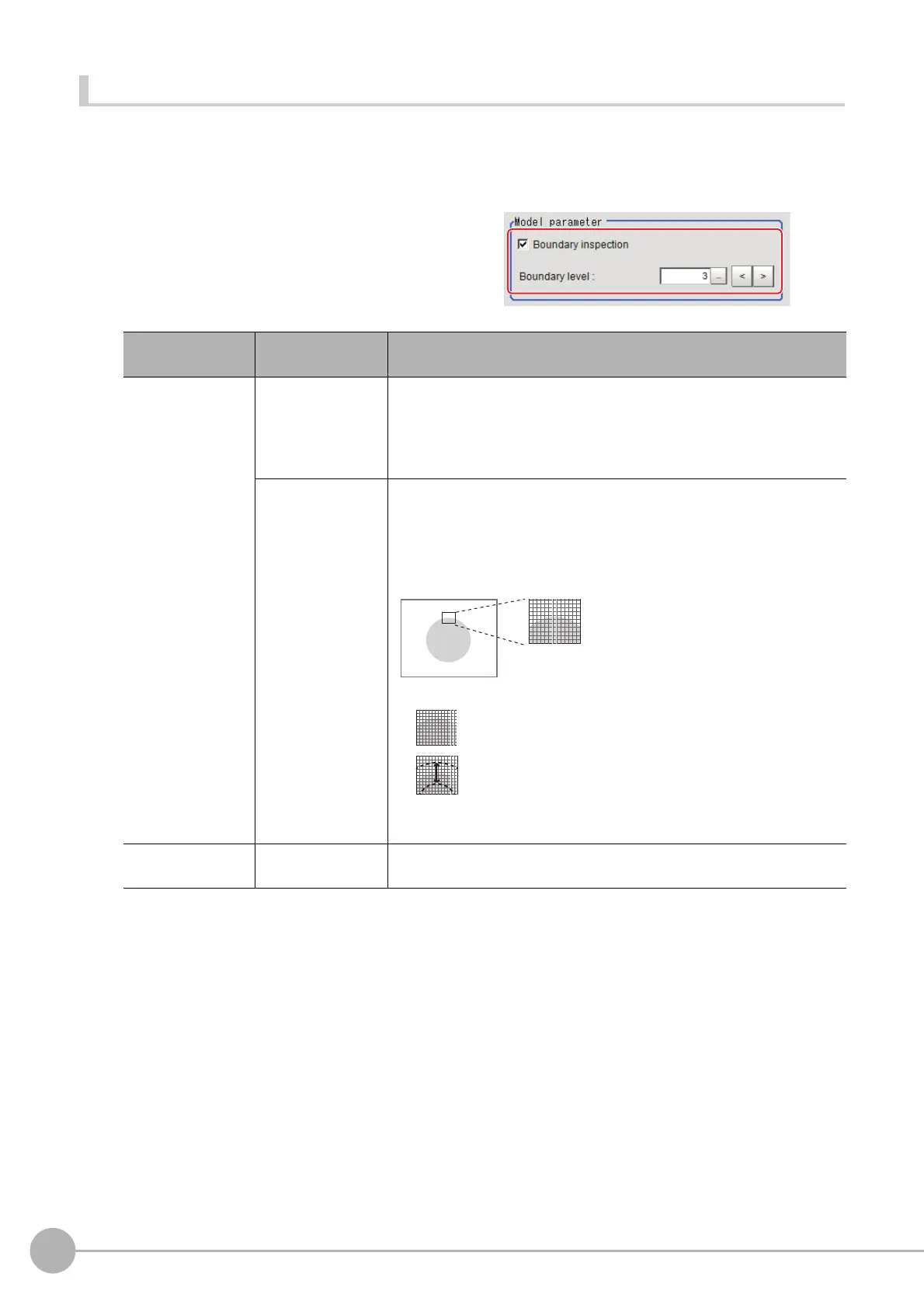

Changing Model Parameters

The range can be changed as needed to address unstable measurement results. Normally, the factory default

value will be used.

After changing a setting, check wheth

e

r measurement can be done properly by performing an actual

measurement.

1 In the "Model parameter" area, specify a

value for each item.

Setting item

Set value

[Factory default]

Description

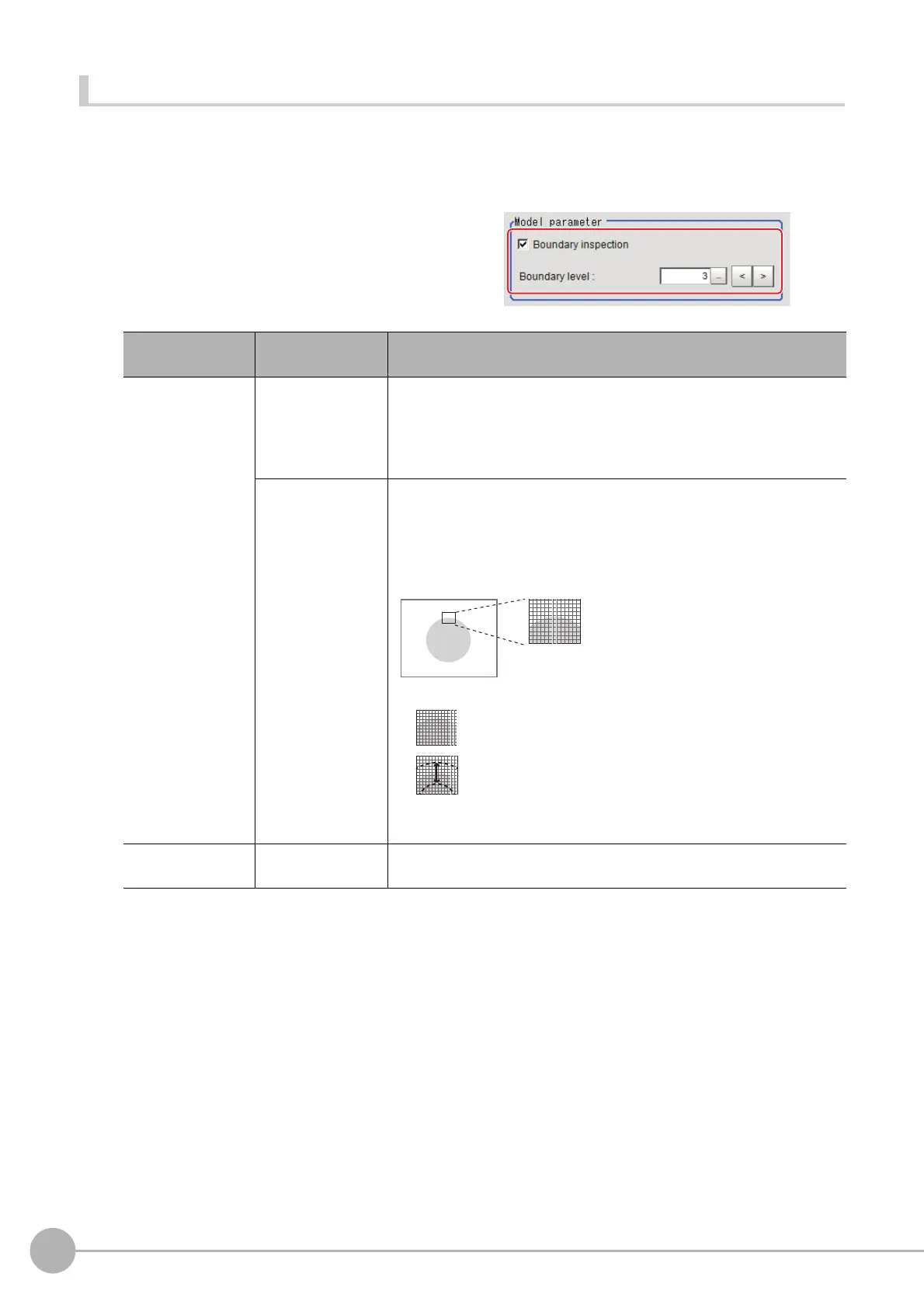

Boundary

insp

ection

[Checked]

Defects around boundaries with color cha

nge

s can also be detected. The

edges similar to those in the model image are not regarded as defects.

Check this option when inspecting defects around boundaries, such as

chips and burrs. Defects along a direction different from the model image

profile are detected in the range of pixels of profile ± boundary level.

Unchecked

Boundary areas are excluded from the in

spection. This can prevent

matching mistakes due to positional deviation of measurement objects,

but defects around boundaries cannot be detected.

"Boundary level" can be used to specify how many pixels around

bou

ndaries should be excluded from the inspection.

Boundary level

0 to 9

[3]

Select the degree of assimilation of variations around boundaries.

Depending on the "Boundary inspection" value, the meaning is different.

If the measurement object moves up slightly,

its difference with the model will be detected as the edge part.

(1 grid = 1 pixel)

Model

Measurement image

When setting Edge Measurement to “Disabled”, the range of

the “Model edge ± Boundary level” will be outside of the

measurement object.

Example) When “Edge level” is 3, the range with a width of

6 pixels will not be outside of the measurement object.

Loading...

Loading...