Advanced Filter

594

FH/FZ5 Processing Item Function Reference Manual

The procedures below are used when a single image is used.

2 Set the parameters.

To register a model after setting the parameters, click [Register model].

The message "Please set model." is displayed when a mode

l has not been registered or a model needs to

be registered. (Except initial state.)

Setting item

Setting value

[Factory default]

Description

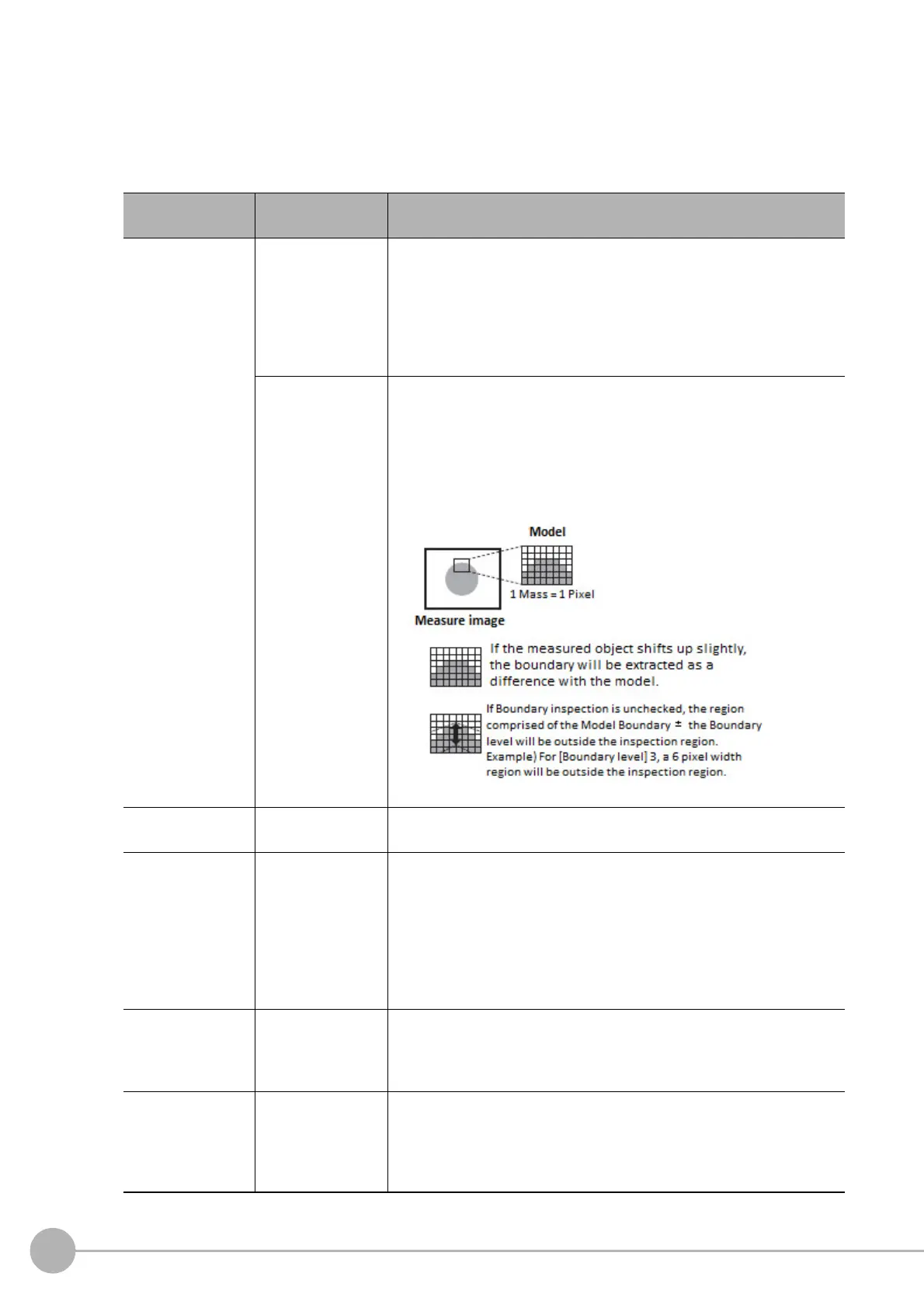

Boundary

insp

ection

• [Checked]

Difference image is used as is in this method.

When the image of the registered mode

l and

the target object after

application can be taken at the same exact position, there is no position

difference between the images so no noise is generated by image

subtraction.

In this case, measurement can be performed more accurately when a

dif

f

erence image is used as is.

• Unchecked

The preset pixel values are deleted from the outline of the extracted

difference image in this method.

Set this method to remove noise caused by position difference of images

when

the

inspection target or camera slightly moves.

The application width is measured to b

e

narrower than the actual width

because information of several pixels is deleted from the difference

image.

Boundary level

0 to 9

[3]

Select the degree of assimilation of variations around boundaries.

The function differs depending on the "Boundary inspection" setting.

Normalization

• Checked

•[Unchecked]

Select whether or not to perform

normalization according to the

brightness at the time of model registration.

When this check box is selected, the density is adjusted before matching,

so tha

t

the matching is not affected by changes in the total image

brightness or the lighting fluctuations.

When normalization is performed on an almost plain object, the total

image

brightness is changed and the measurement does not work

correctly.

Perturbation

• Checked

•[Unchecked]

When this check box is selected, a correction is made befor

e

matching in

order to prevent false detection of slight positional deviation of

measurement objects as differences.

However, this requires more processing time.

Difference

0 to 255

[50]

This sets the reference gradation used

w

hen calculating differences

between the model and the inspected object image.

Pixels with a difference equal to or grea

te

r than Difference are converted

to white and other pixels are converted to black, so that only defects are

converted to white and measured.

Loading...

Loading...