1/05

10-7

DocuColor 12/DCCS50

Principles of Operation Overview

Principles of Operation

Reissue

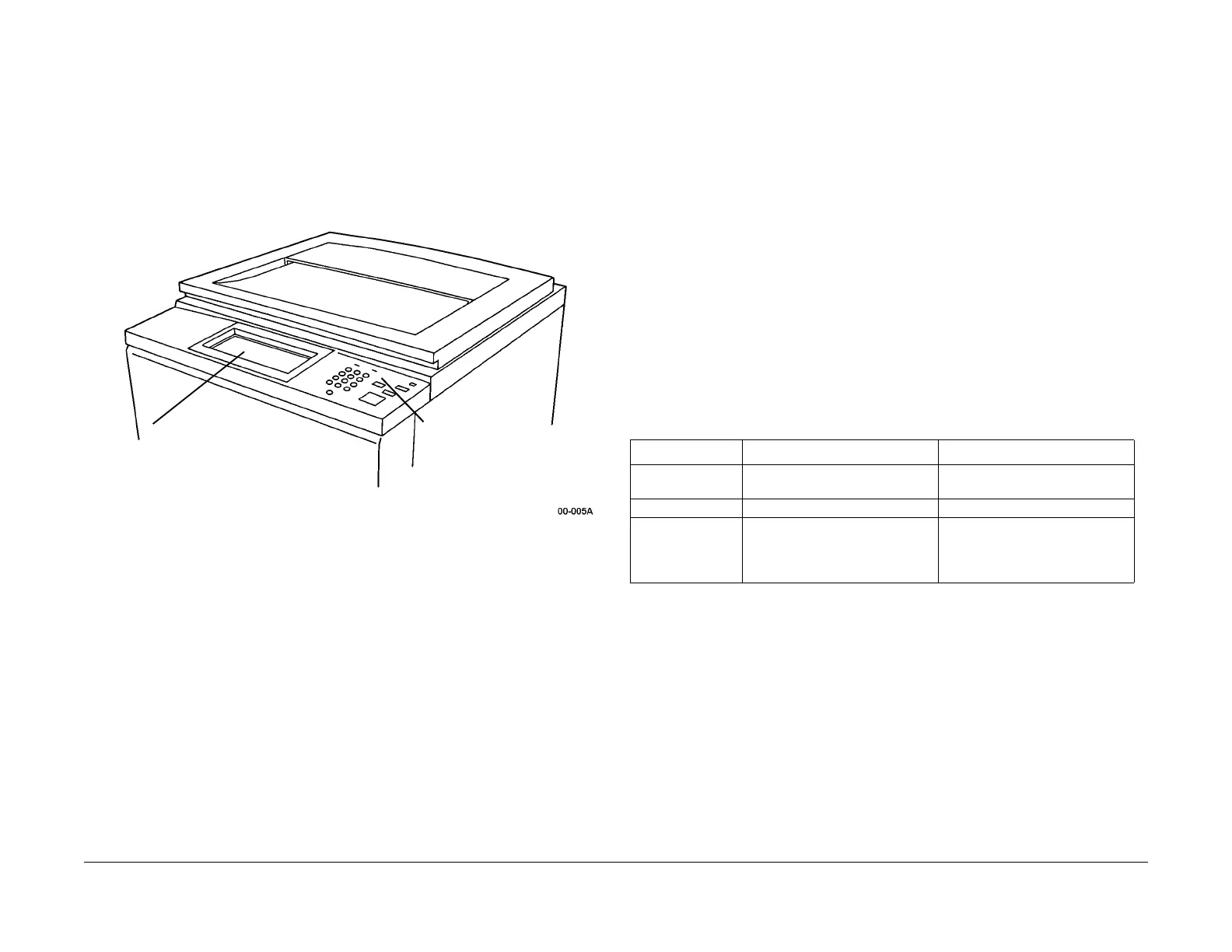

Local User Interface

The local User Interface, shown in Figure 2, includes the Control Panel, the optional Edit Pad

Assembly and the electronics associated with these assemblies. The User Interface sends

operator commands to Machine Run Control, and displays messages and graphics in

response to commands from Machine Run Control. The displayed messages and their lan-

guage can be changed by downloading software from a Portable Workstation (PWS) con-

nected at the rear of the machine.

Figure 2 User Interface

Remote User Interface

When the machine is configured as a printer or Copier/Printer/Scanner, its Digital Front End

(DFE) appears as an Internet or Intranet server. Users can send their print jobs to the machine,

and retrieve images, which have been scanned from the Platen Glass.

Machine Run Control

Machine Run Control is the hardware and software that controls machine printing and copying

operations. It accepts status information from all machine subsystems and controls their oper-

ation. Specifically, Machine Run Control performs the following functions:

• It analyzes and implements operator inputs from the User Interface and sends display

messages

for the operator to the User Interface.

• It receives status inputs from machine sensors and prov

ides timing and sequencing

instructions to machine motors and clutches.

• It identifies machine faults, initiates appropriate recovery operations and notifies the oper-

ator.

• It provides cycle-up and cycle-down commands to all other subsystems.

Start Power

Start Power refers to the motors and drives which are activated when the START button is

pressed on the User Interface, or downloads a print file from a remote user workstation. Start

Power is comprised of the Main Motor and the Photoreceptor Motor and their associated driv-

etrains. However, these two motors do not provide all of the mechanical drive in the machine.

Mot

ors

powering other machine subsystems are described in the chapters associated with

these subsystems.

Document Transportation

In a machine configured as a Copier or Copier/Printer/Scanner, the document is placed on the

Platen Glass. This can either be done manually by the user or automatically by the Duplex

Automatic Document Feeder (DADF) (Figure 4). In both cases, the machine can automatically

determine the size of the original document.

A machine configured as a Copier/Printer/Scanner can also sc

an document

s, and the resulting

images are routed to a user client workstation by the DFE.

Imaging

Imaging is the acquisition and processing the document image, up to being written to the Pho-

toreceptor Drum. As shown in Table 1,

the source and destination of the image depends on the

machine configuration.

Scan and copy images are created at the IIT when the Xenon lamp illuminates the original doc-

ument on the Platen Glass, and the Charge Coupled Device (CCD) samples the document at

400

dots

per inch (DPI). The image is then manipulated by the Image Input Terminal (IIT) and

the Image Processing System (IPS):

1. They determine if the original docum

ent

is color or monochrome

2. They digitize the analog data from the CCD

3. They separate the image into its component colors

4. They perform any other processing, such as image

enlargement or reduction, that the

user has specified

When copying, the image is routed to additional processing circui

try in the Image Output Termi-

nal (IOT). The IOT circuitry drives the laser diode in the Raster Output Scanner (ROS). This

diode wr

ites the latent image onto the Photoreceptor Drum.

TOUCH PAD and

LEDS

LCD TOUCHSCREEN

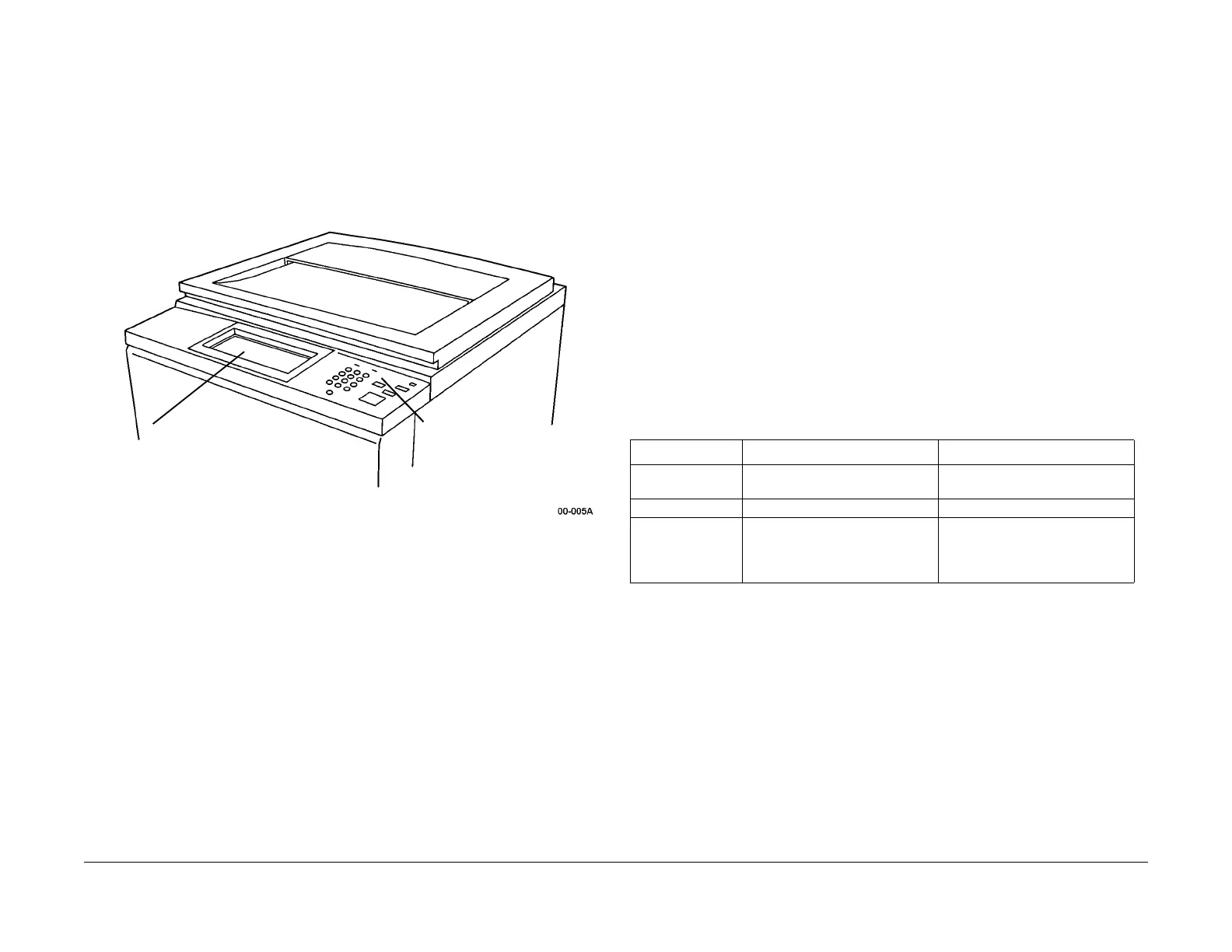

Table 1 Image Sources and Destinations

Configuration Image Sources Image Destinations

Printer User workstation via LAN and

DF

E

Photorecept

or Drum

Copier IIT Photoreceptor Drum

Copier/Printer/

Scanner

IIT

or

User

workstation via LAN and

DF

E

Photorecept

or Drum

or

User workstation via DFE and

LAN

Loading...

Loading...