1/05

10-151

DocuColor 12/DCCS50

Print Transport through the Mailbox/Sorter

Principles of Operation

Reissue

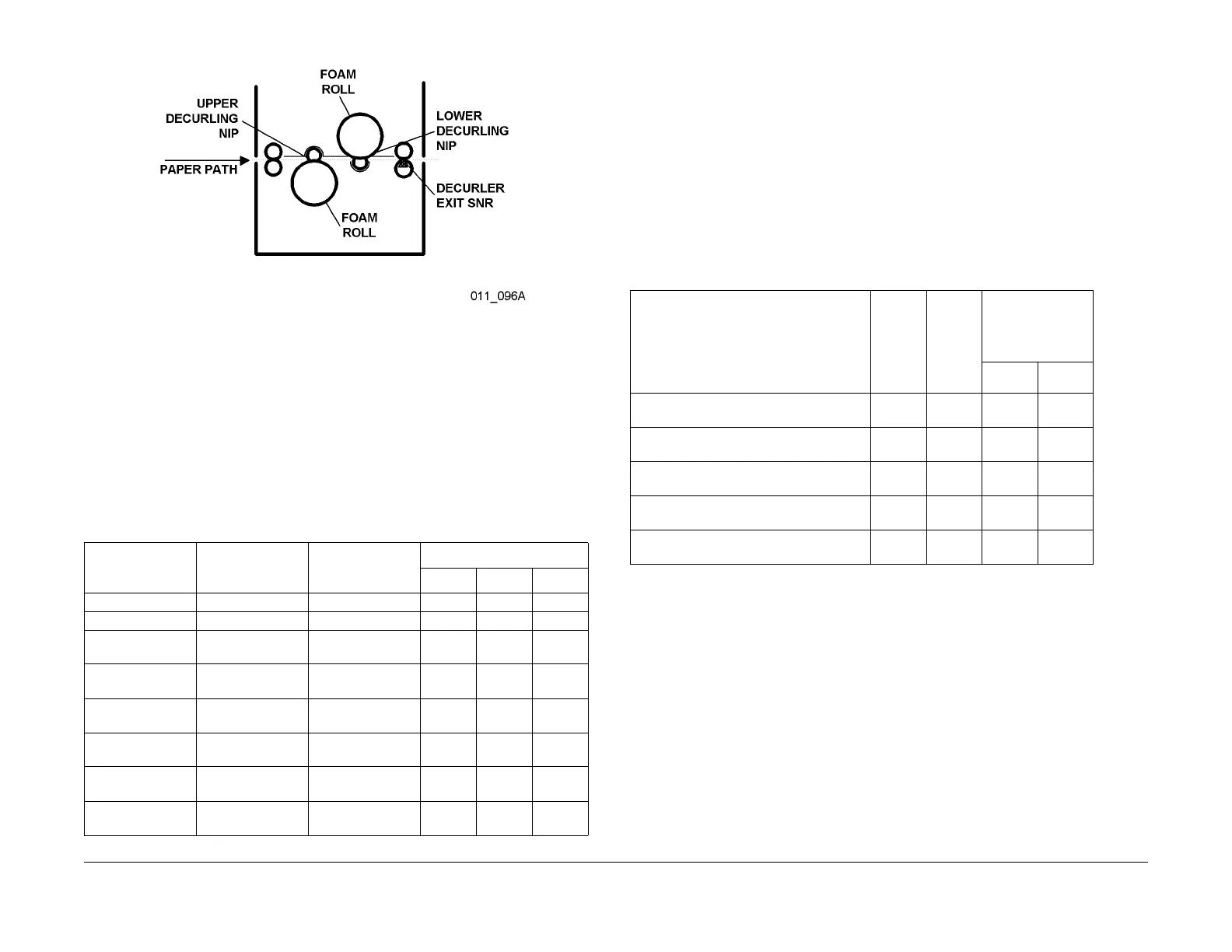

Figure 1 Paper Decurling components and function

Therefore, prints exiting with image side down are forc

ed through the Upper Decurling Nip with

2, 6 or 10 mm of shift and through the Lower Decurling Nip with no nip shift. The controls

required for this function originate in the machine IOT CPU PWBA. This information is then

sent through the Mailbox/Sorter Control PWBA to the Decurler Control PWBA. This last PWBA

regulates the amount of Nip Shift and which nip is shifted. Ta b le 2 shows the distance of the

Nip Shift in the Decurling Roll for various paper types and copy modes.

The Decurler transport speed is to match the transports speed of the copy job through the

xerogr

aphics proces

s. The speed of the Decurler Motor is determined by the IOT CPU PWBA.

OCT Gate Control

The OCT Gate is moved up or down by the OCT Solenoid. This gate diverts the copy material

to either the bins or to the OCT. The status of the OCT Gate is determined by the IOT CPU

PWBA, which sends an appropriate message to the Mailbox/Sorter Control PWBA. The Mail-

box/Sorter Control PWBA enables or disables the OCT Solenoid as required.

Mailbox/Sorter Control

The sorter and mailbox functions use the same hardware. The difference between them results

from the configuration of the attached machine and the type of print or copy job being per-

formed. These differences result in different control messages from the IOT CPU PWBA and

dif

ferent

control signals from the Mailbox/Sorter Control PWBA. In particular, the machine con-

figuration determines whether sorter or mailbox f

unct

ionality is available. Table 3 shows the

types of collating functions that are available for the different machine configurations.

Sorter Functions

NOTE: Sorter operation is possible only when the Mailbox/Sorter is attached to the Digital

Copier machine (DC).

When a Sorter is connected to the Digital Copier, four (4

) different finishing outputs are avail-

able. See Table 3 f

or these outputs.

When the Mailbox/Sorter is configured as a Sorter, the user c

an select from the User Interface

screen either Sort Mode or Stack Mode for outputs to the bins. Copies for bin output are

diverted into the Vertical Transport area of the Sorter by the OCT Gate. At the appropriate bin

level, a bin solenoid energizes to push a Bin Diverter Gate (one gate per output bin) into the

paper path. This directs the copy into that bin. The selection of the Bin Diverter Gate is made

by the Sorter Control PWBA in response to control messages from the IOT CPU PWBA. The

appropriate Bin Solenoid is energized only as the copy enters the vertical transport area. When

the trailing edge of the copy passes the Bin Sensor, the Bin Solenoid deenergizes to close the

Bin Gate.

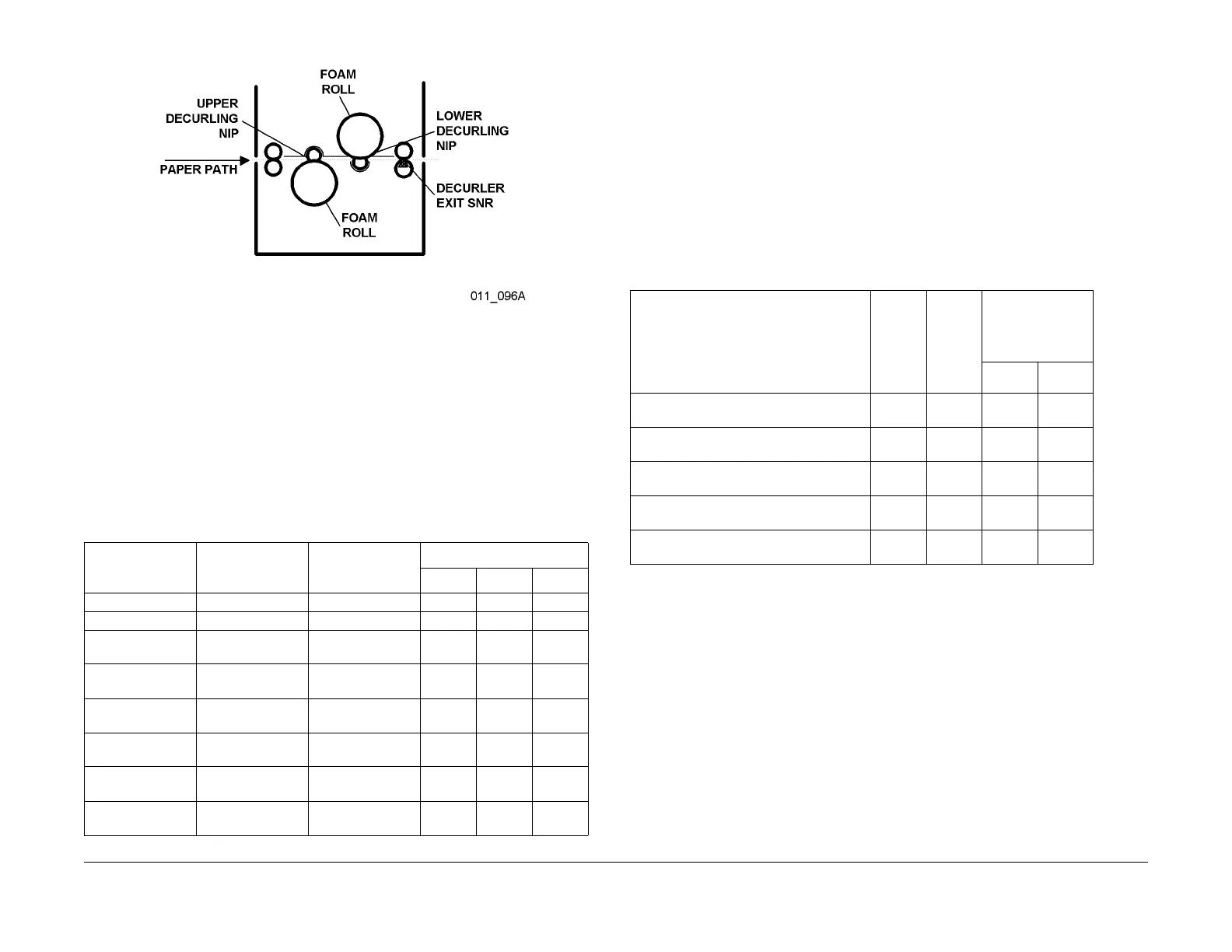

Table 2 Decurler Shift Requirements & Motor Speeds

Media Type Image Type Transport Speed

Decurler Roll Nip Shift

2 mm 6 mm 10 mm

Transparency Black and White 160 mm/sec X

Transparency 4-Color 60 mm/sec X

Lightweight Plain

Pape

r

Bl

ack + 1 Color 160 mm/sec X

Lightweight Plain

Paper

4-Color; I

mage

Density < 50%

160 mm/sec X

Lightweight Plain

Paper

4-Color; I

mage

Density > 50%

160 mm/sec X

Heavyweight Plain

Paper

Black +

1 color 60 mm/sec X

Heavyweight Plain

Paper

4-Color; I

mage

Density < 50%

60 mm/sec X

Heavyweight Plain

Paper

4-Color; I

mage

Density > 50%

60 mm/sec X

Table 3 Functions for different configurations

Output Functions

Printer

(P

R)

Only

M

ailbox

Copier

(DC)

Only

Sorter

Copier/Printer

(DC/PR)

Mailbox

f

unct

ioning as a:

Copier Printer

Sorts into bins

(1,2,3...1,2,3...etc.)

X

Stacks into bins

(1,1,1...2,2,2...etc.)

X

Sorts into bins by user

(User A: 1,2,3...User B: 1,2,3...etc.)

X X

Offset Catch Tray (OCT)

straight stack

X X X X

Offset Catch Tray (OCT)

offset stacks

X X X X

Loading...

Loading...