1/05

10-103

DocuColor 12/DCCS50

Paper Feeders

Principles of Operation

Reissue

• When rotating clockwise, it raises the Tray Lifter in the Paper Tray.

• When rotating counterclockwise, it rotates the Nudger and Feed Rolls for the tray.

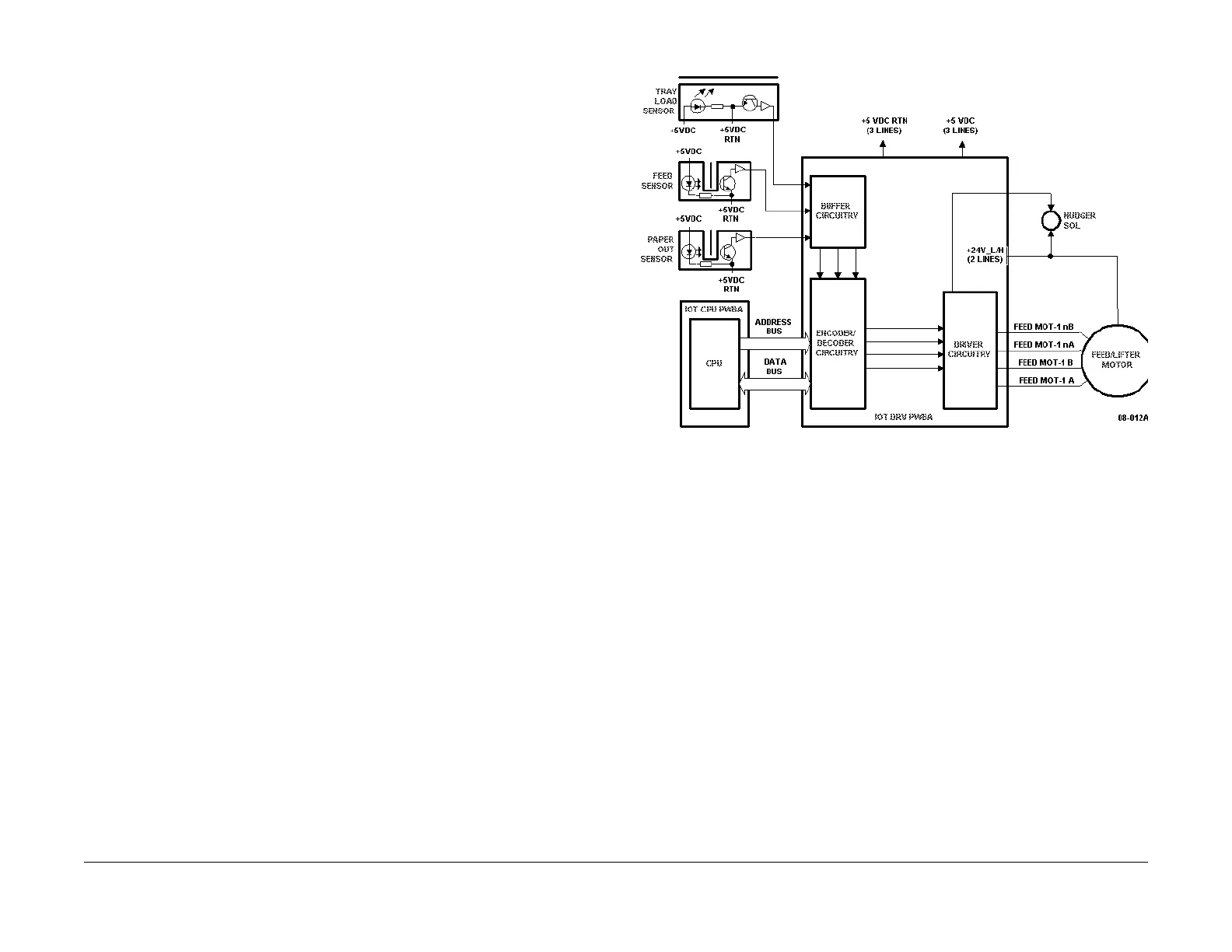

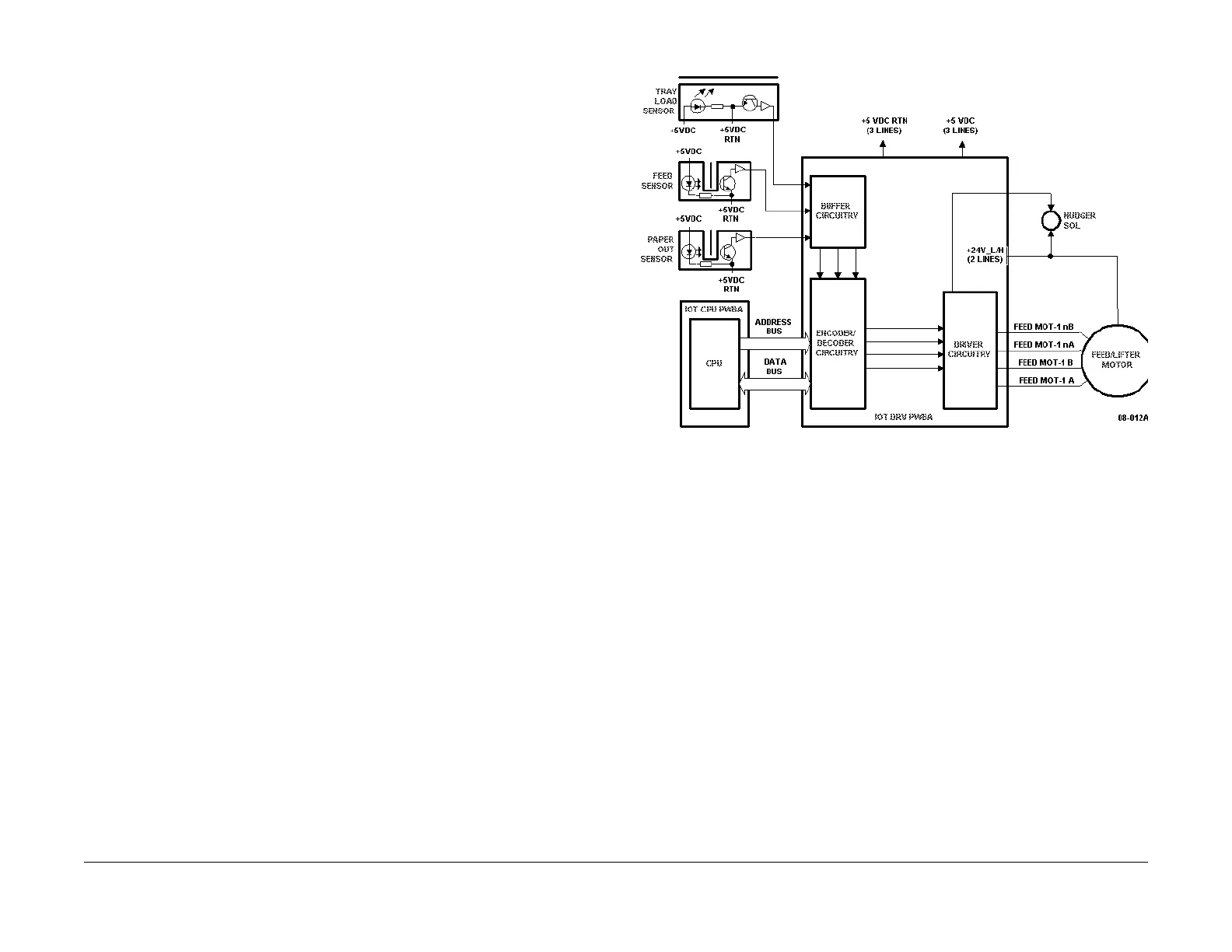

The Feed Motors are controlled by the IOT Control and Drive PWBAs. The circuit is the same

for

all four Paper Trays and their Feeder Assemblies. See Figure 2 for the electrical schematic.

The paper feed process starts either when:

• The machine functioning as a printer, receives a print job from the network connection.

• The machine functioning as a copier, the user enters a print job on the User Interface cor-

rectly, provides the document in the Document Feeder or on the Platen Glass and

presses t

he Start Button, and there is the correct copy material in one of the paper supply

sources.

Paper Feed

The IOT Control PWBA manages paper feed timing using the TR0 signal from the IBT Belt as a

reference. In the selected tray, the Feed Motor is energized, rotating the Nudger Roll, and the

Feed Roll. The Retard Roll rotates by being cammed against the Feed Roll. For each sheet of

paper to be fed, the Nudger Roll solenoid momentarily activates, allowing a spring to push the

Nudger Roll down to the top sheet of paper in the tray. The Nudger Roll feeds the paper into the

nip of the Feed/Retard Roll. The paper is fed at a rate of 300 mm/sec. to the Take Away Rollers.

If the lead edge of the paper is not sensed by the Pre-Feed Sensor within the correct time dura-

tion, then a Feed Sensor jam is declared. (See Tray Level Lift and Sensing for maintaining the

p

aper level

in the Paper Trays)

Retard Roller Operation

The Retard Roll prevents more than one sheet of paper from being fed into the paper path at

the same time.

The Retard Roll in each Paper Tray is classified as a semi-active type. The Retard Roll is

mechanically camm

ed against the motor-driven Feed Roll when the Paper Tray is inserted into

the machine. The rotation of the Retard Roll comes from this contact with the Feed Roll.

A friction clutch on the shaft of the Retard Roll provides rotation resistance. When there is no

copy

, or a single sheet

of copy in the nip of the Retard/Feed Roll, the resistance from the fric-

tion clutch is not enough to prevent the Retard Roll from rotating with the motor-driven Feed

Roll.

Th

is allows the rotating Retard and Feed Rolls to feed a single sheet of copy. If more than

one sheet of copy is fed into the Retard/Feed Roll nip, then the resistance from the Friction

Clutch is greater than the resistance between the multiple sheets of copy. This resistance pre-

vents the Retard Roll from rotating, which holds the extra sheets of copy back in the tray while

only t

he

top copy is advanced by the motor-driven Feed Roll.

Paper Feed Control

Figure 2 is a partial electrical schematic of the paper feed control.

Figure 2 Partial electrical schematic for paper feed control in Trays 1-4

Loading...

Loading...