1/05

10-133

DocuColor 12/DCCS50

Process Controls

Principles of Operation

Reissue

There are several different control routines which Process Controls runs in order to maintain

consistent image density and color balance. The following Table lists the routines and shows

when and what is performed.

Setup Mode

Most of the Process Controls routines run as setup routines. There are other routines that run

during Run Mode or during Standby Mode.

The Setup Mode will be split into two groups:

• Setup routines in Diagnostics - These are proc

edures that are performed by the Service

Representative while running Diagnostics routines.

• Setup routines that run automatically - These ar

e procedures which Process Controls will

run automatically and are a subgroup of Diagnostics.

Setup routines in Diagnostics

The Service Representative enters Max Se

t Up from the Diagnostics menu to perform the bal-

ance of the Setup routines. The Max Set Up menu includes nine (9) routines:

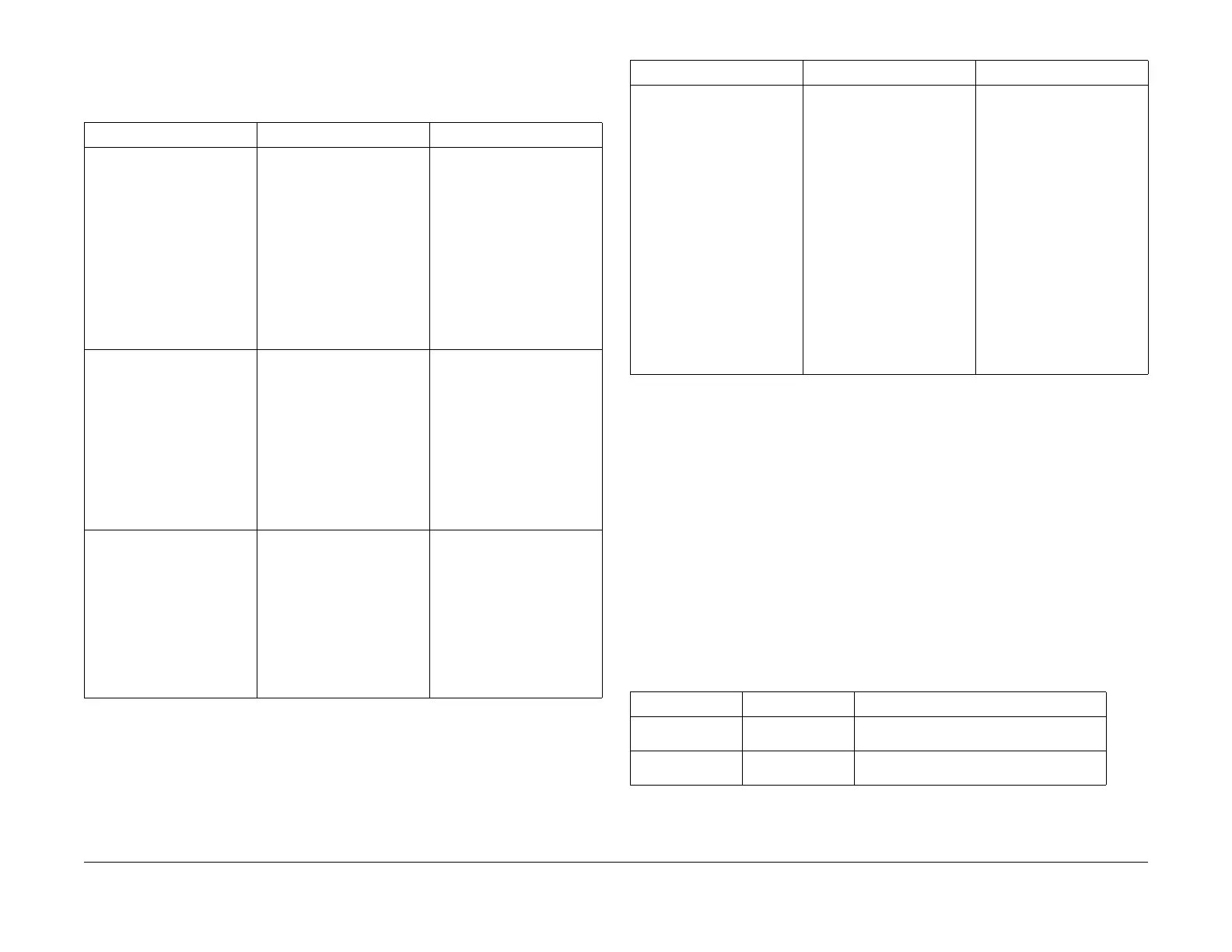

Table 1 Process Controls routines

CONTROL ROUTINE WHEN PERFORMED WHAT IS PERFORMED

Max Set Up Performed in Diagnostics by

t

he Serv

ice Representative

• At machine install

• After changing the ADC

S

ensor,

ENV Sensor,

Developer Housings or

developer materials

• During repair or cleaning

o

f t

he xerographics

• During any service call

as

a precaution measure

• Adjust color density

Any or all the following sub-

routines can be performed:

• ESV Sensor check

• Environmental Sensor

(ENV

) check

•

Vh/Vm Setup

• ADC Automatic Gain

Control (AGC

) Setup

• ADC Setup

• IOT Hi-light Setup

• Color Balance Setup

Mini Setup Runs automatically at the start

of th

e first job after:

• Power up, if the Fuser

t

emperat

ure has

dropped below 120°C

• Rest (Stand-by Mode) of

m

ore t

han 4 hours

• When Fuser temp is less

than 120°C

Tw

o subroutines run in the

order l

isted:

• Vh/Vm Setup

• Two patches are made

f

or each color and

read

by the ADC to determine

the amount of toner to

dispense

• Using the same patch

readings as

in previous

rout

ine, set TRC Cont 1

Checkup Runs automatically at the start

o

f th

e first job after:

• Power up, if the Fuser

t

em

perature is above

____°C

• A paper jam

• 30 minutes of elapsed

t

ime si

nce the last

Checkup

• end of a job run

One Subroutine runs:

• Vh/Vm Setup

Run Mode Control Runs automatically during all

jobs

The following items are con-

trolled:

• Vm patch is made and

l

as

er diode (LD) power is

adjusted about every 12

IBT cycles and at the

end of every job,

depending upon paper

size.

• Toner dispensing is con-

trolled by pixel count

(I

CDC) and

periodic

ADC readings (approx.

every 13 copies, depend-

ing upon paper size)

• Using the same patch

readings a

in previous

reading, set

TRC Cont2

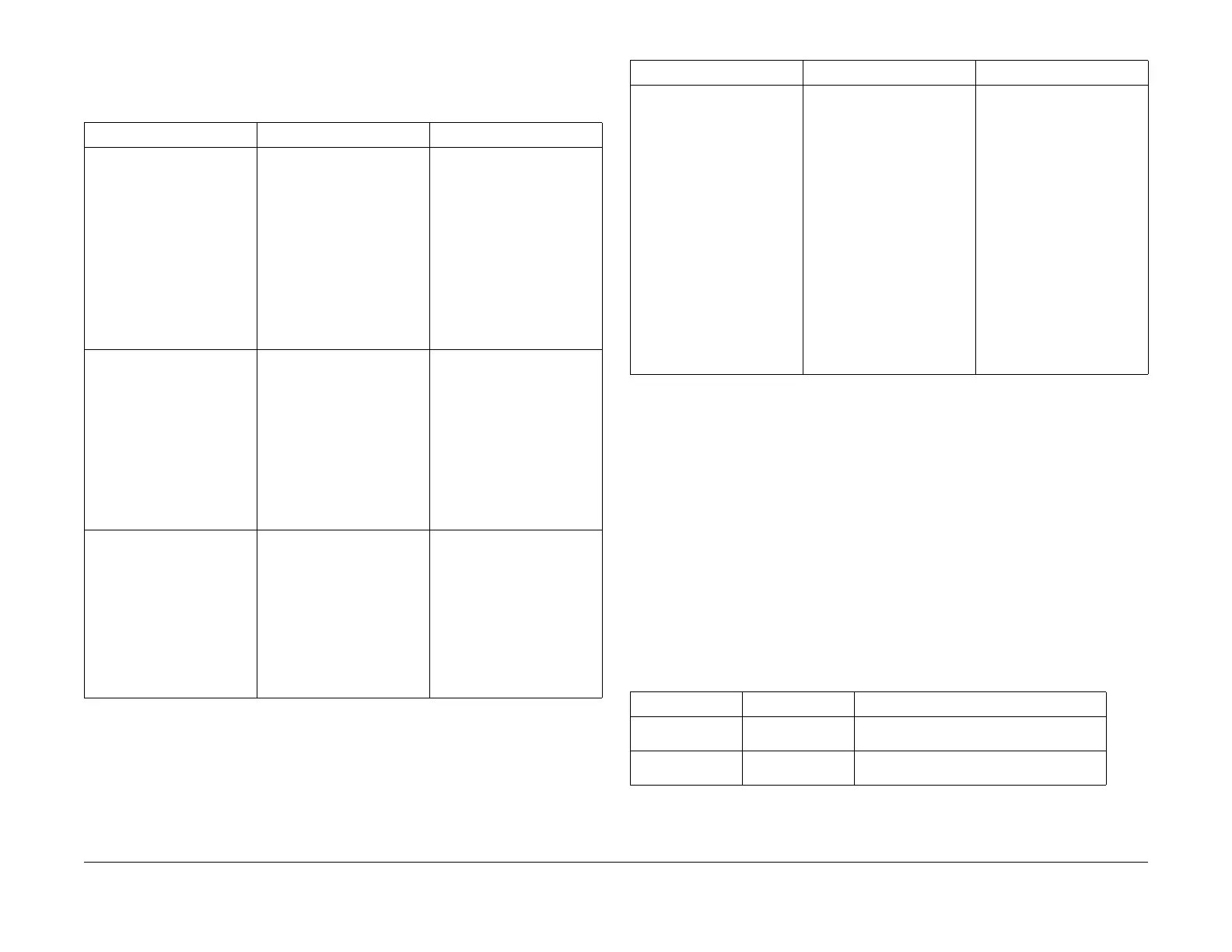

Table 2 Max Setup Routines

Diagnostic Code Description Contents

dC945 IIT Calibration IIT and CCD Calibration, and White Refer-

ence Adjustment

dC934 ADC/AGC Setup Adjusts ADC Sensor gain to get a constant

Vclean

Table 1 Process Controls routines

CONT

ROL RO

UTINE WHEN PERFORMED WHAT IS PERFORMED

Loading...

Loading...