1/05

10-105

DocuColor 12/DCCS50

Tray 5

Principles of Operation

Reissue

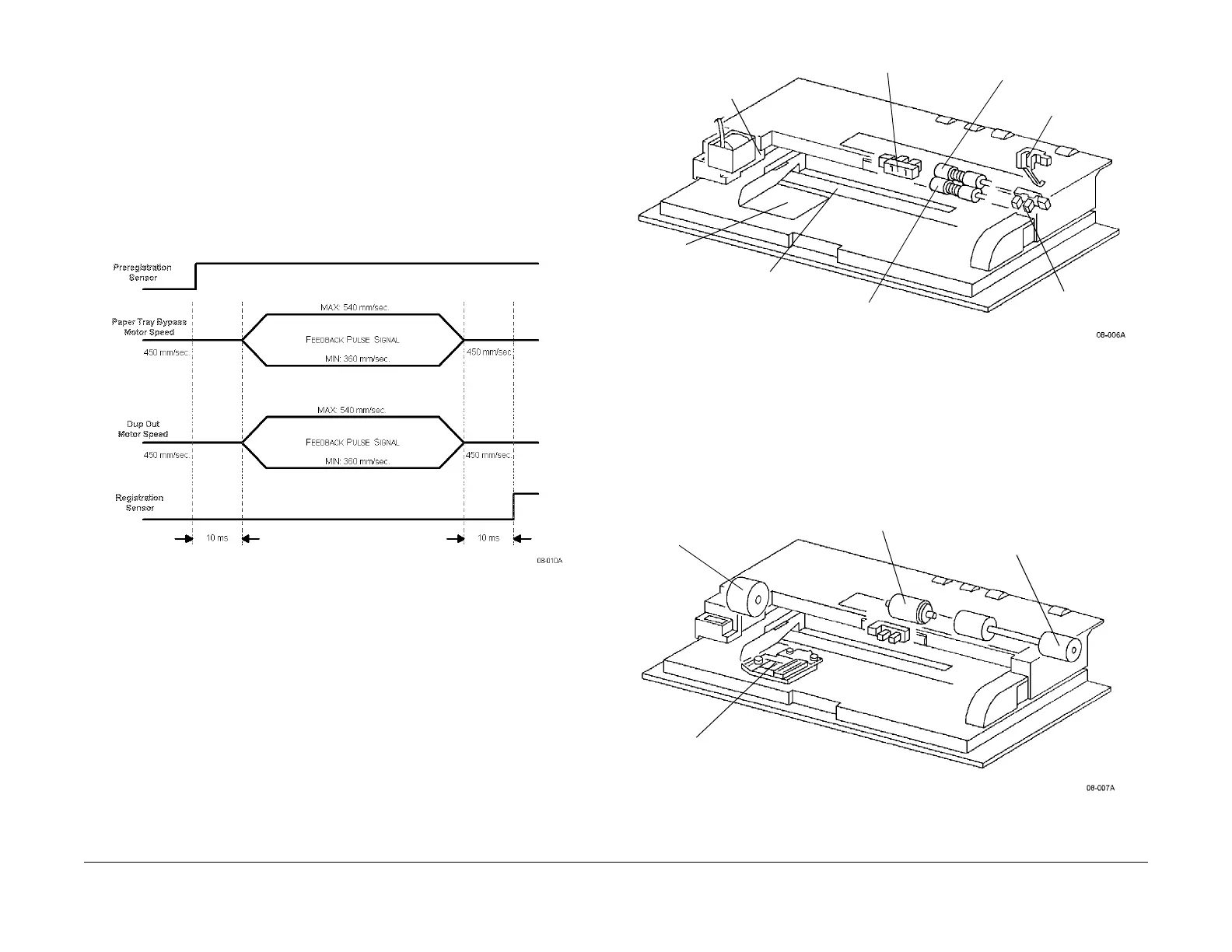

As the paper advances through Tray 5 Take Away Rolls, the lead edge of the paper passes a

reflective sensor. The signal from this sensor is compared to the TR0 signal from the IBT by the

machine run control. The machine run control signals Tray 5 Motor to run the Take Away Rolls

faster or slower so that the paper will synchronize with the IBT for proper image transfer.

The same alignment procedure occurs when the p

aper com

es from the Vertical Transport and

Paper Tray direction. In this case, a Preregistration Sensor signals the machine run control

which has the Tray 5 Motor vary the speed of the Preregistration Rolls. Refer to Figure 1 for

Tray 5 Motor speed adjustments of these rollers. From either Tray 5 Take Away Rolls or the

Preregistration Rolls, the copy is advanced to the Registration Rolls for “deskewing”. (See

Paper Registration and Paper Transport to the IBT Belt.)

Figure 1 Motor Speed Adjustments for Paper and Image Alignment

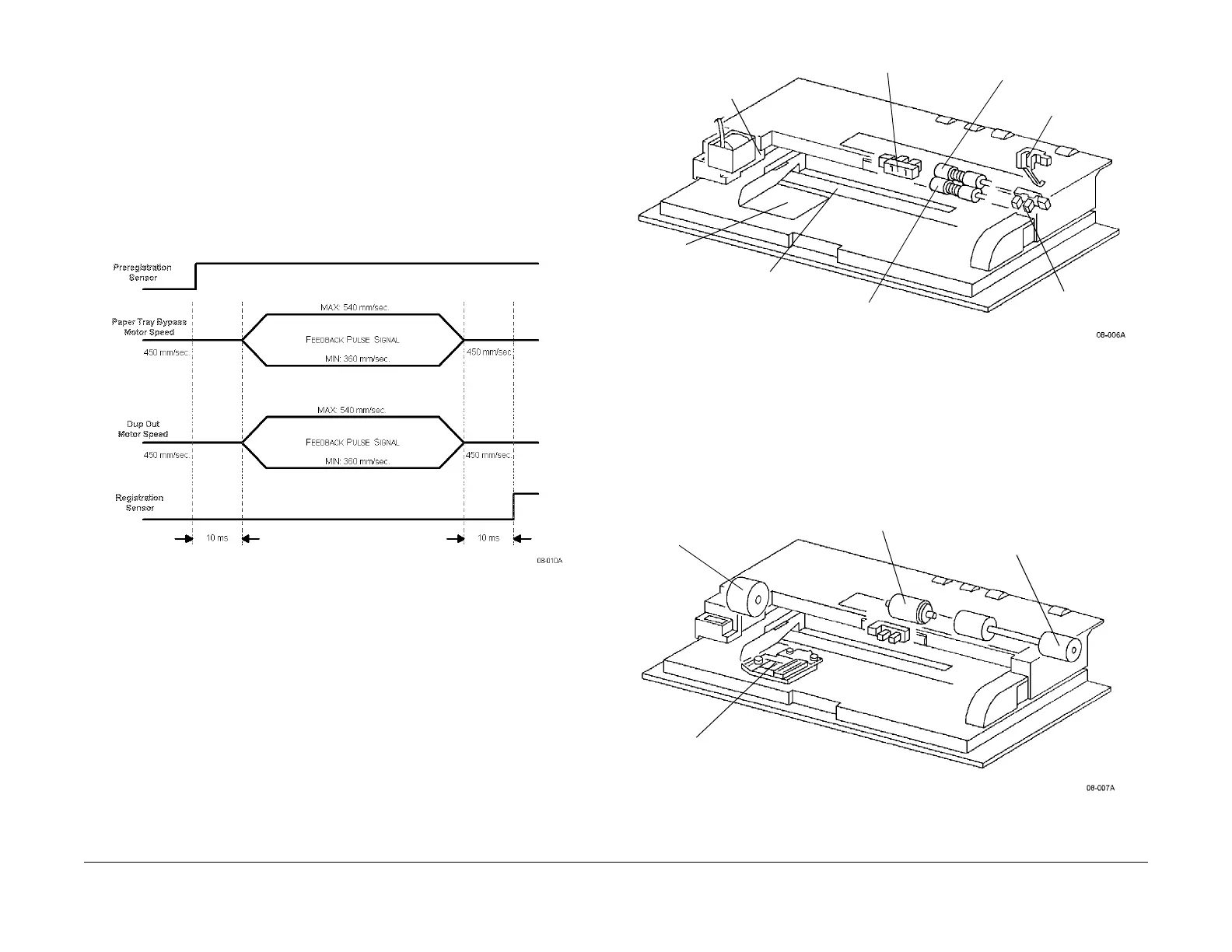

Tray 5 Mechanical Drives

Tray 5 uses two motors:

• Tray 5 Motor drives

Tray 5 Nudger roll, Tray 5 Feed Roll, Tray 5 Take Away Rolls, Pre-

Registration Rolls and Take Away Rolls #1.

• Tray 5 Lifter Motor raises or lowers the Paper Lifter to control the paper level for correct

feed height

in Tray 5.

- Clockwise raises the Paper Lifter

- Counter clockwise lowers the Paper Lifter

Figure 2 Tray 5 components

Tray 5 Copy Size Sensing

When paper is placed in Tray 5, a paper Size Guide is manually adjusted to accommodate the

lead edge dimension of the copy. The Size Guide uses a variable resistor sensor (0-5 VDC) for

providing the lead edge dimension to the machine run control. The length of the paper (run

dimension) is determined by the activation time of the Pre Fuser Sensor.

Figure 3 Tray 5 Drive and Size Sensor

SIZE

GUIDE

PAPER TRAY

LIFT

FEED OUT

SENSOR

NUDGER ROLL

SOLENOID

RETARD ROLL

FEED ROLL

PAPER OUT

SENSOR

PAPER LEVEL SENSOR

Tray 5 Motor

Nudger Roll

Tray 5 Take Away Roll

Paper Size Sensor

Loading...

Loading...