1/05

10-134

DocuColor 12/DCCS50

Process Controls

Reissue

Principles of Operation

Setup routines that run automatically

Process Controls must automatically perform setup operat

ions at frequent intervals in order to

maintain image quality. The setup routines which run automatically are one of two types,

depending on the conditions: Mini Setup or a Checkup.

Mini Setup

The Mini Setup consist of three subroutines:

1. Vh/Vm Setup

Th

is electrostatic routine is the same as DC933. This routine may result in new set values

for t

he Charge Corotron Grid Voltage (Vg) and Laser Diode power (LD) to maintain a Vh

equal to -650 volts and a Vm approximately equal to -350 volts (voltage varies with humid-

ity and Photoreceptor Drum cycles).

2. ADC P

atch

readings

This developability routine causes ADC patches to be made for each color. The patches

are measure by th

e ADC and if the values are different than the target values, the Run

time dispensing algorithm is adjusted. See Run time toner dispensing for more informa-

tion.

3. T

RC CONT 1

Checku

p

There is only one routine in the automatic Checkup routin

e. This routine is Vh/Vm Setup

described previously. This runs because the electrostatics need to be checked more often than

developability. There are three separate conditions which will cause a Checkup to run:

1. When power is switched on to the machine and t

he Fu

ser temperature is above 120°C, a

Checkup will run automatically. This condition occurs when the power has been off for a

short time and the Fuser has not had the time to cool down. A full Mini Setup is not

required for this condition.

2. A Checkup will run after a paper jam has occurred.

3. Whenever 30 minutes has elapsed since the last Checkup.

Run Mode

There are 3 routines which run while copies

are being made. Process Controls uses these rou-

tines to monitor and adjust the electrostatics and developabilit

y parameters in order to maintain

copy quality. These routines are: LD CONT, Toner Dispense Control and TRC Control.

Standby Mode

When the machine is resting in Standby, there are no setup routines running and none of the

electrost

atic or developability parameters need to be controlled. The only function Process

Controls is doing during Standby is keeping track of elapsed time. This is done to track the time

between jobs to determine if a Checkup or Mini Setup is required.

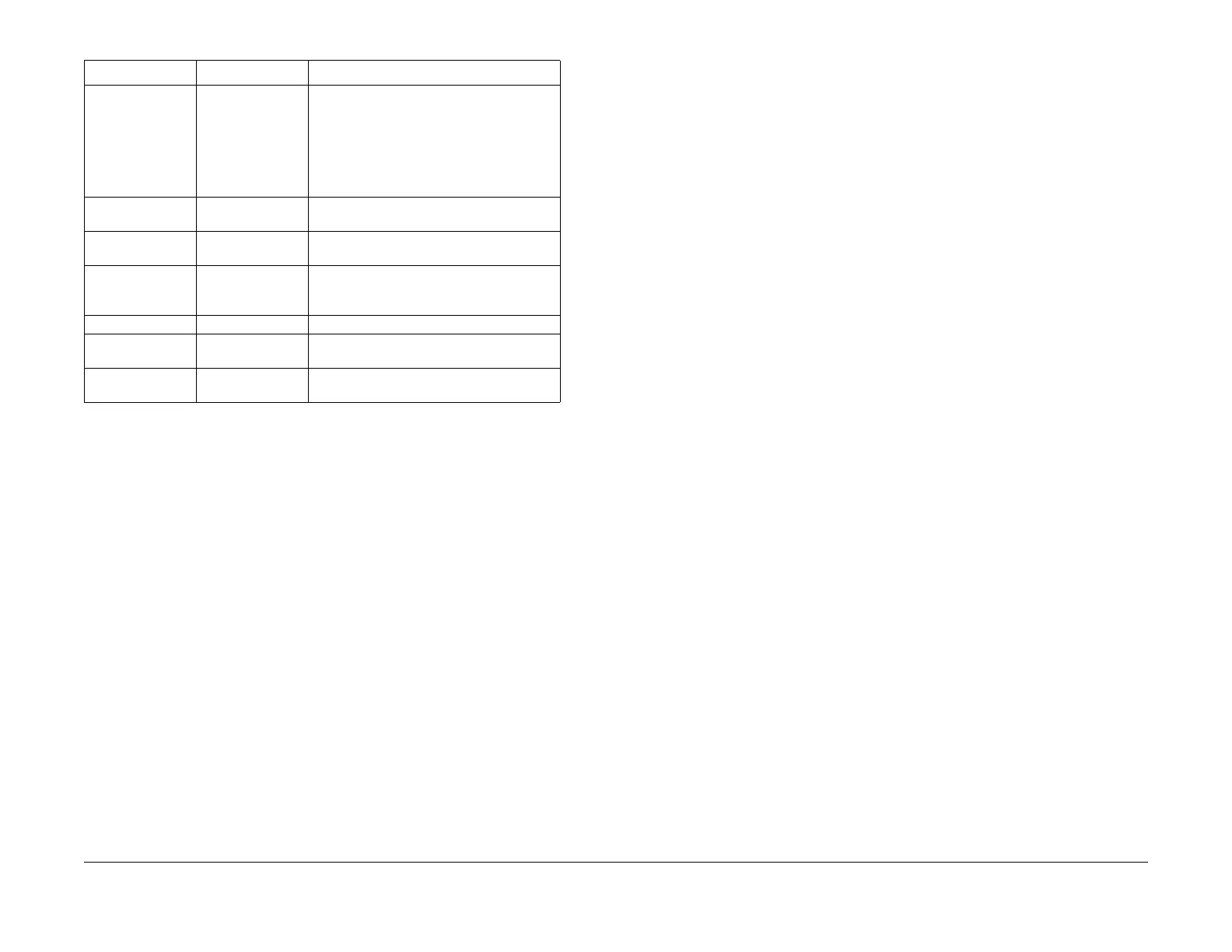

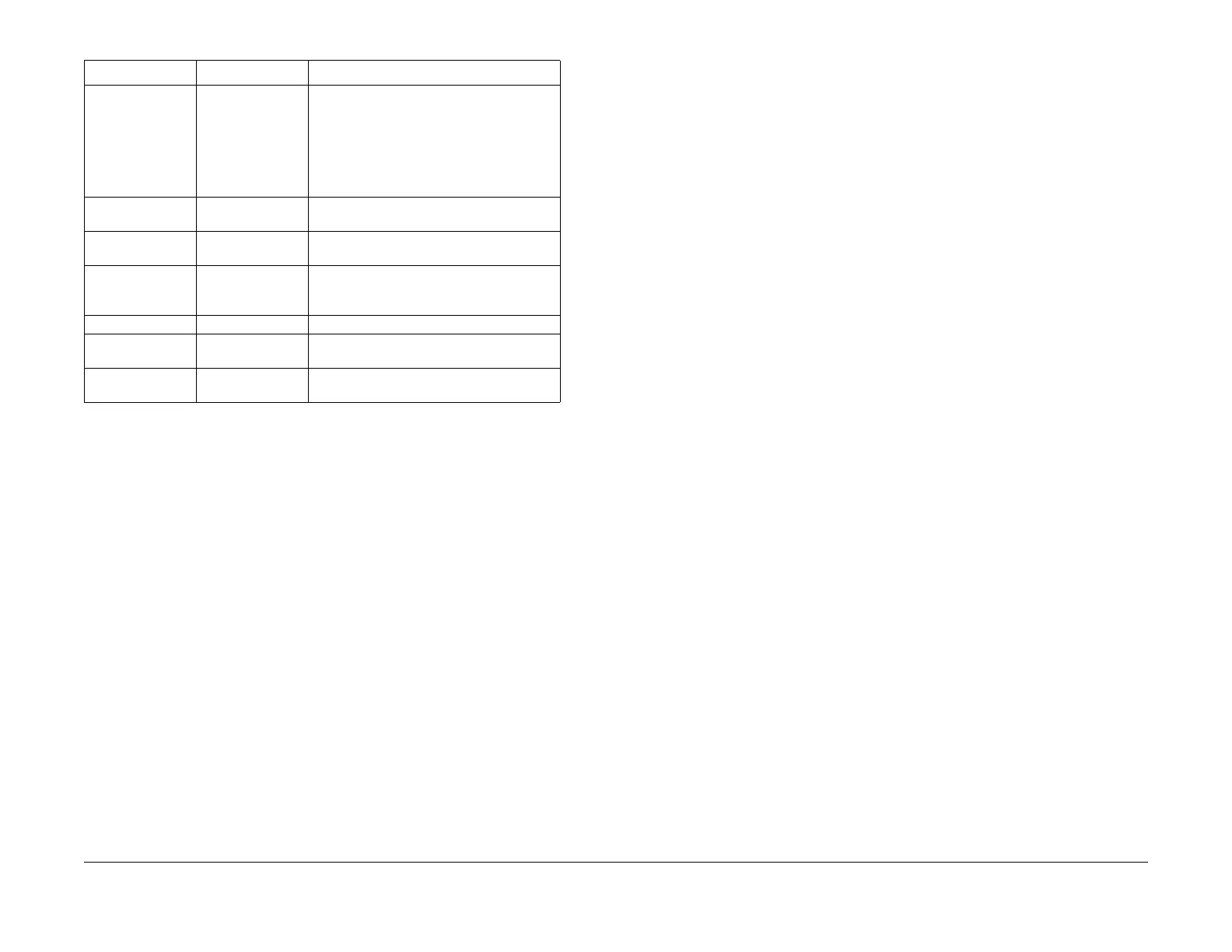

dC933 VH/VM Setup Adjusts VG/LD/BIAS to achieve the target

VH

, VM

Changes

VH/VM target to extend Develop-

ment and Photoreceptor life.

Changes ADC target by Environmental Sen-

sor (humidity)

Changes ASG Bias to keep V10% constant

dC918 IOT Highlight

Se

tu

p

Adjusts Highlight legible and in/out balance

by ASG Bias

dC923 ProCon PG Print PCON pattern (w/o LUT) and shows

ADC pat

ch values.

dC922 TRC CONT Makes a TRC LUT based on 2 ADC patches

on th

e IBT Belt. If ADC is >D60% (0.3) Tone

Up/Tone Down is required (w/o paper)

dC924 TRC Adjust Adjusts density by TRC LUT offset manually

dC939 TRC Check PG Print PCON pattern with LUT for TRC adjust-

ment

dC919 Color Balance Adjusts a center value of user color balance

m

ode (for

Digital Copier only)

Table 2 Max Setup Routines

Diag

nostic Code Description Contents

manuals4you.commanuals4you.com

Loading...

Loading...