1/05

10-160

DocuColor 12/DCCS50

The Decurler, The Finisher Gate

Reissue

Principles of Operation

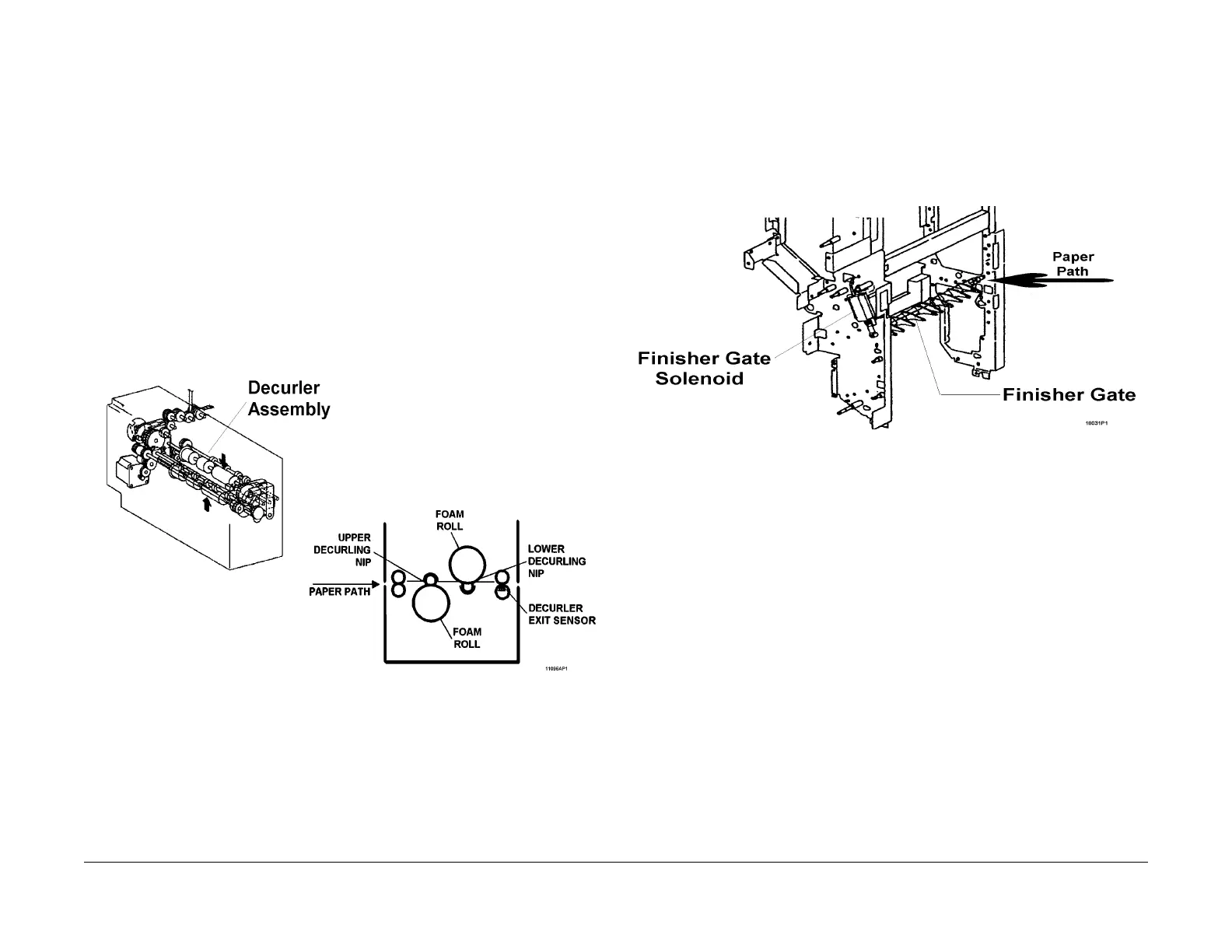

The Decurler

Paper exiting the fuser is fed first through the Decurler. The Decurler is capable of correcting

curl up, or curl down. This is achieved through the use of two sets of rollers (Figure 1).

The first set of rollers in the Decurler Assembly will correct for curl up. This is accomplished

thr

ough the use of two rollers, one larger and made of a soft, foam material, and the other is a

metal rod. The foam roll is positioned over the top of the paper path. The metal rod is located

below the path. When the paper enters the decurler, and if it is to be processed for curl up, the

two rolls will come together with the paper between them. Because the top roll is soft, the lower

rod will slightly deform it, and the paper will pass through the nip created at this point. The

shape of the nip will remove the curl from the paper as it passes through.

To reduce curl down, the second set of rolls in the Decurler are used. In this set of rolls, the

f

oam

roll is on the bottom of the path and the metal rod is on the top. The rolls come in contact

with each other and the paper is passed through the resulting nip.

The decurled media is then passed into the Finisher.

Figure 1 Decurler Assembly and Paper Path

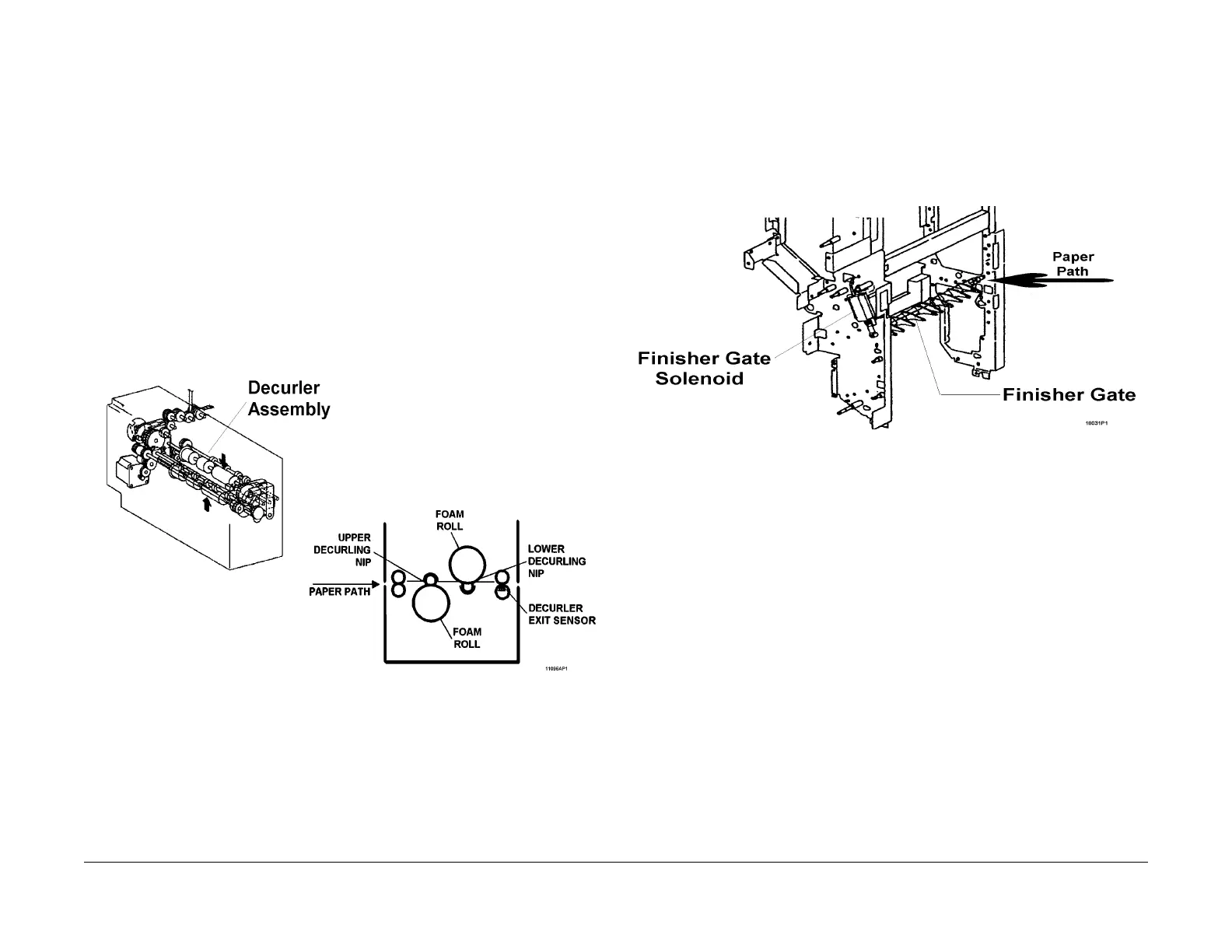

The Finisher Gate

The Finisher Gate is the first point at which the paper in the path can be diverted to either the

Finisher or the Sorter/Mailbox (Figure 1).

The gate consists of a rod with fingers that is controlled by t

he Finisher Gate Solenoid. The Fin-

isher Gate Solenoid is a latching solenoid. When a signal is received from the Finisher PWB,

the

solenoid will either lift the gate to send paper to the Finisher, or lower it to send paper to the

Sorter/Mailbox.

Figure 1 Finisher Gate

manuals4you.commanuals4you.com

Loading...

Loading...