1/05

10-100

DocuColor 12/DCCS50

Overview

Reissue

Principles of Operation

For Duplex printing, the paper travels further into the duplex path to a “dup point.” At this posi-

tion, the paper has passed a second Mylar gate. The copy reverses direction, driven by the

Duplex Invert

er Roll, and the Mylar gate guides the paper to the Dup Path. Two sets of pre-

alignment rolls (Duplex In Roll and Duplex Path Roll) drive the copy, while three sets of crossed

rolls (Alignment Rolls 1, 2 and 3) push the copy into the Side Guide Rail for alignment prior to

copying on the second side.

Duplex Out Rolls transport the copy to the Preregist

rat

ion Rolls. From there, the copy is again

de-skewed and sent for copying on the second side by passing through the IBT, Fuser and then

exiting the machine as a finished duplex copy.

Refer to T

able 1 f

or information on the different drive motors used to transport the paper

through the machine.

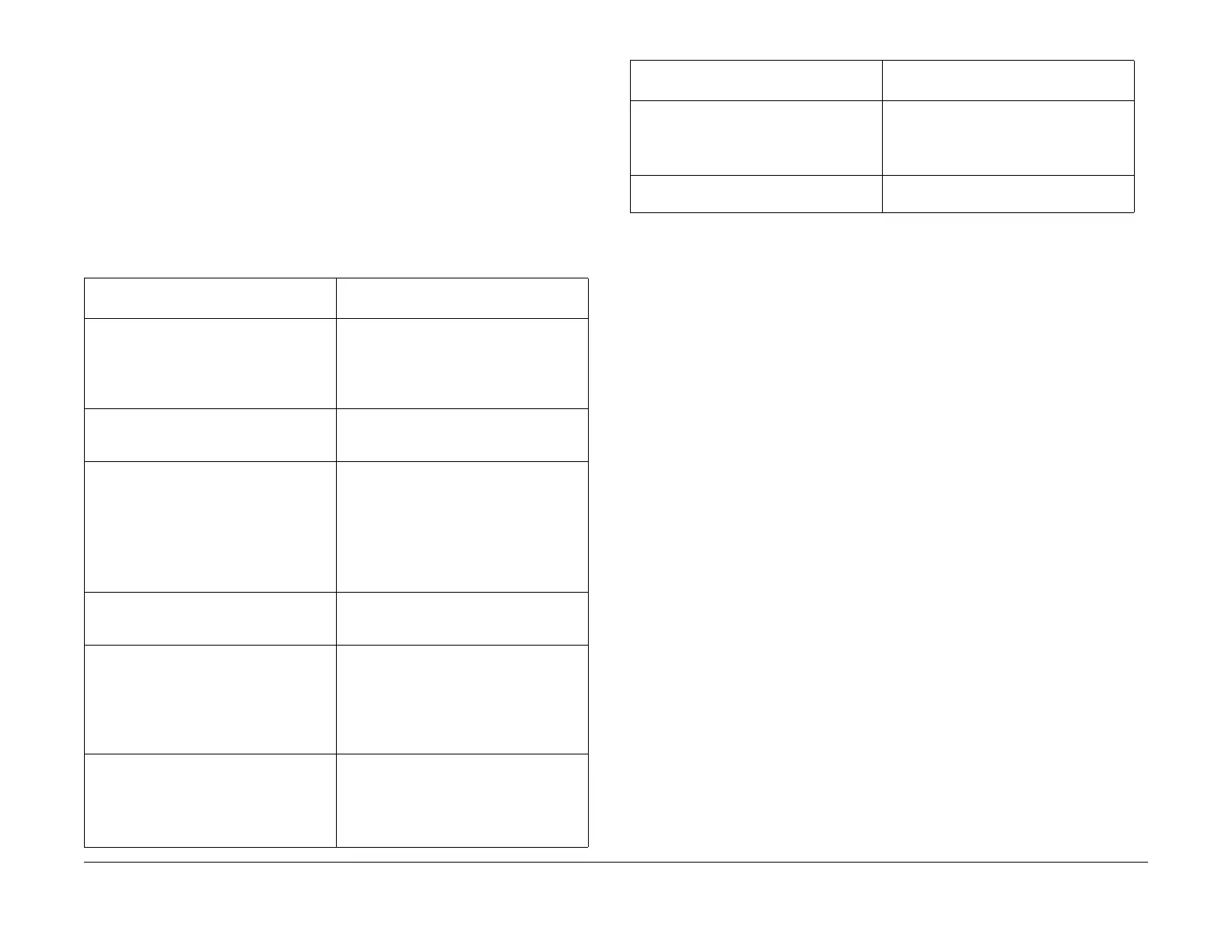

Table 1 Paper Transport Motors

Motor

Function

(drives the following:)

Trays 1-4 Feed/Lift Motors

•24 VDC

• Bidirectional Stepper Motor

• 300 mm/sec (feed operation)

• Feed Roller (ccw)

• Nudger Roller (ccw)

• Paper Level Lift (cw)

Take Away Motor

•24 VDC

•450 mm/sec.

• Take Away Clutch

– Take Away Rollers 2-4

Tray 5 Motor

•24 VDC

•220 mm/sec.

•130 mm/sec.

•60 mm/sec.

• Tray 5 Feed Clutch

– Nudger Roll

– Feed Roll

• Tray 5 Take Away Roll

• Take Away Feed Clutch

– #1 Take Away Roll

• Pre-Registration Roll

Tray 5 Lifter Motor

•24 VDC

• Stepper Motor

• Tray 5 Lifter-Up

• Tray 5 Lifter-Down

Regi Motor

•24 VDC

• Stepper Motor

•220 mm/sec.

•130 mm/sec.

•60 mm/sec.

• Registration Roll

Invert Motor

•24 VDC

• Reversing Stepper Motor

•350 mm/sec.

•450 mm/sec.

• Invert Roll 1

• Invert Roll 2

•Dup Invert Roll

• Dup In Roll

• Dup Path Roll

Duplex Out Motor

• 24 VDC

• Align Roll 1

• Align Roll 2

• Align Roll 3

• Dup Out Roll

Exit Motor

• +/- 24 VDC

• Machine Exit Inverter Roll

• Pressure Roller Cam

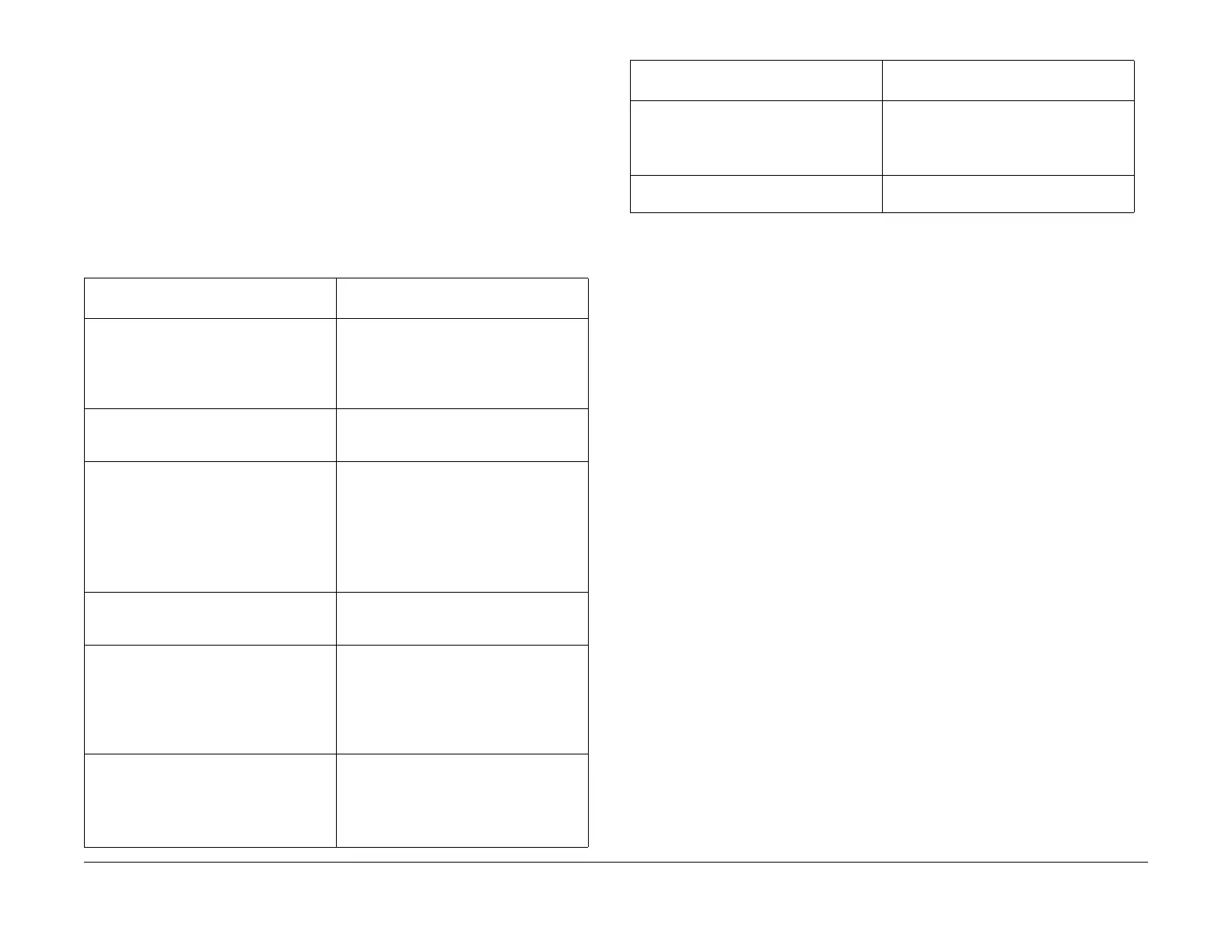

Table 1 Paper Transport Motors

Mo

to

r

Function

(drives the following:)

manuals4you.commanuals4you.com

Loading...

Loading...