1/05

3-31

DocuColor 12/DCCS50

IQ 30 Fuser Offsetting RAP

Image Quality

Reissue

IQ 30 Fuser Offsetting RAP

Toner that was not cleaned off the Heat Roll offsets onto the front or back side of copies.

NOTE: Offsetting is most likely to occur when running long jobs of high area coverage, trans-

parencies or coated papers. High AC transparencies should be run

using paper interleaves.

Offsetting is also likely to occur when running heavy paper in the normal paper mode. Offset-

ting is more likely to occur as the Heat Roll ages.

Initial Actions

• Perform the Fuser Nip (dC701) ADJ 8.1.1. If the nip width is very low at one end, check

that the Heat and Pressure Roll Bearings are correctly positioned. Also check that the

Pressure Roll Lift mechanism is functioning properly. Ensure that the 2 screws holding the

upper and lower Fuser Frames together are tight.

• In some cases, highly contaminated fuser oil can lead to offsetting, especially with trans-

parencies and black copies. This situation is possible under the following circumstances:

– The machine has a low oil supply (i.e., oil bottle is empty oil tank is low/add oil mes-

sage is displayed).

– Oil level on the copies is low (indicated by the lack of oil streaks).

– The machine has high copy volume (more than 100K) and the oil in the tank is milky/

dirt

y.

–

Low Humidity environments may increase the likelihood of offsetting.

If this is suspect, replace the Oil Tank and Oil Pipe (PL 8.

7) and the Oil Wick and Oil Filter

(PL 8.7), then go to the GP 1 Fuser Break-In Procedure.

• Excessively high Fuser temperature is a primary cause of

Fuser contamination. This

problem is prevalent when the machine is run in Extra Heavyweight mode, and increases

when high area coverage images are run frequently. If this is suspect, change the default

values for the NVM locations in Table 1 to the values listed in the New values column.

Procedure

Remove the Fuser Assembly. Check the following components. Clean excess toner from the

components using the Cleaning Procedures in Section 1. Replace the components if contami-

nation remains or if offsetting continues after cleaning.

• Heat Roll (PL

8.3)

•

Pressure Roll (PL 8.

3)

• External Heat Roll (PL 8.

8)

• Donor Roll (PL 8.

9)

• Pick Up Roll (PL 8.

9). If Roll is replaced, also replace the Metering Blade (PL 8.9).

•Oil Wick (PL 8.7)

• Cleaning Roll (PL 8.5)

Perform the actions indicated below:

• Check the Oil Bottle, if empty, replace (M

achine Consumables).

•

Check the Oil supply system is functioning. Go to the OF10-2 F

user Oil Pump RAP.

• Check that the load springs and bearings for the

Donor Roll Assembly are properly posi-

tioned.

• Advance the web manually to a clean area. Access NVM location 777-079 and increase

the value by 7,

000 for each 25mm/one inch that the web was advanced.

• Run the Fuser Break-in Procedure G

P

1 Fuser Break-In Procedure.

• Check for indications that the Web Supply Roll is rotating normally. If there is a buildup of

ton

er across the entire length of the web, perform the Web Motor Checkout.

Web Motor Checkout

+24 VDC is measured between P

/J413A-

2 on the IOT Drive PWB and GND.

YN

+24 VDC is measured between P/

J440-1 on

the Web Drive PWB and GND.

YN

Go to F

lag 1 on BSD 10.5 and check the harness for an open circuit. If the harness is

OK

, replace the Distribution PWB (PL 9.3).

+24 VDC is measured between P/J440-2 on

the Web Drive PWB and GND.

YN

Check the Web Motor (PL 8.

4) f

or an open circuit. If it is OK, replace the Web Drive

PWB (PL 8.4).

Go to Flag 2 on BS

D 10.5 and check the harness for an open circuit.

Enter DC330 [10-032] Web Motor. Press the Star

t button. The voltage at P/J413A-2

decreases from +24 VDC to less than +1.0 VDC.

YN

Replace the IOT Drive PWB (PL

9.

2). Install the Web CRU, Front Cover and Oil Car-

tridge.

Replace the Web Drive PWB (PL 8.4). If

that does not correct the problem, replace the Web

Motor (PL 8.4).

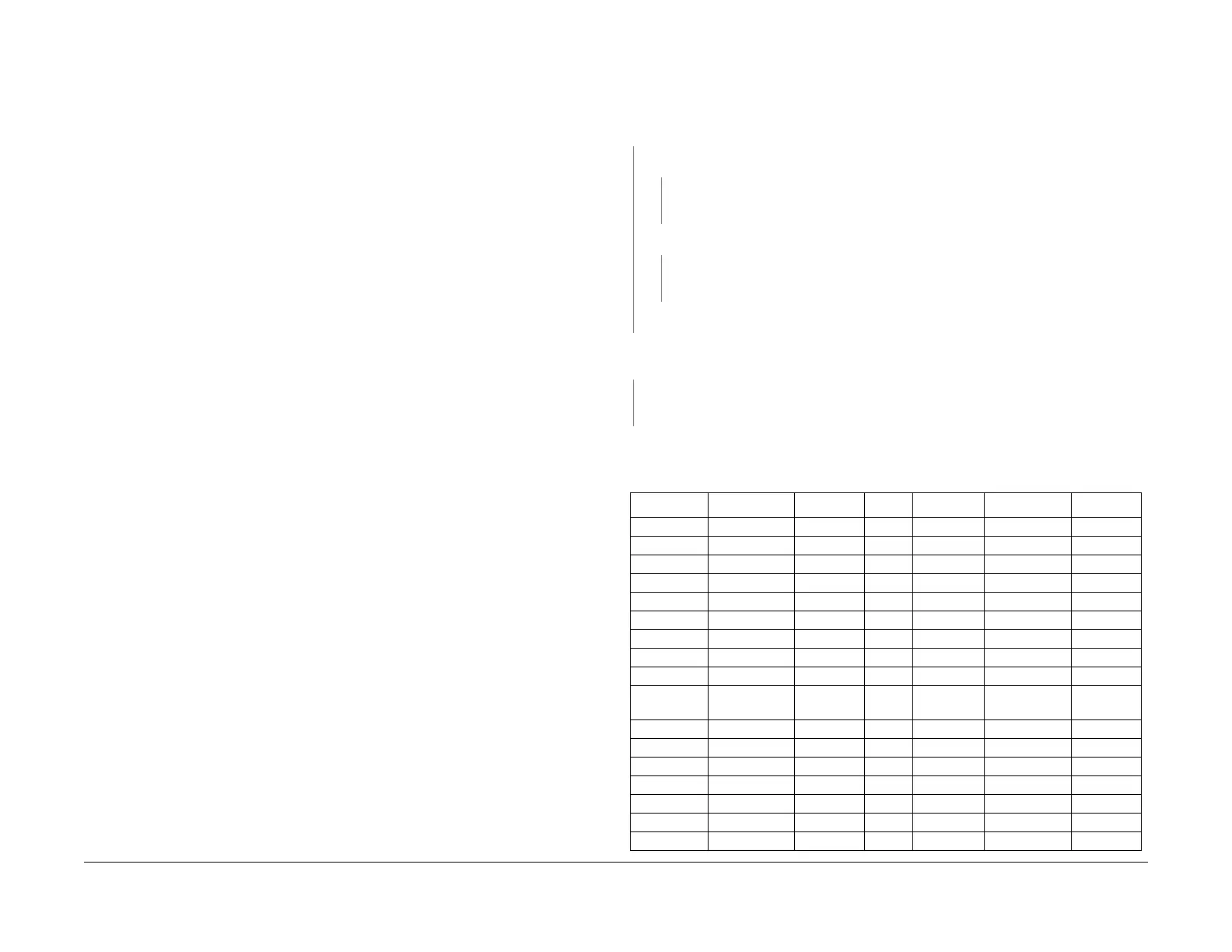

Table 1 Fuser temperature NVM values

NVM loc. Default value New value NVM loc. Default value New value

777-001 160 155 777-137 190 183

777-003 178 170 777-138 183 180

777-005 150 145 777-139 195 188

777-010 165 161 777-166 164 156

777-013 158 153 777-194 185 165

777-016 180 170 777-195 182 165

777-017 193 183 777-196 190 170

777-018 165 156 777-256 1050 18000

777-019 187 167 777-257 1050 25000

777-020 193 (NASG)

185

(ESG

)

172 777-272 165 161

777-021 162 156 777-276 160 155

777-023 163

151 777-280 156 151

777-026 161 155 777-299 193 175

777-027 164 155 777-300 10 2

777-028 162 150 777-301 168 161

777-098 163 155 777-309 168 161

777-135 193 188 777-310 169 163

Loading...

Loading...