1/05

10-120

DocuColor 12/DCCS50

Development

Reissue

Principles of Operation

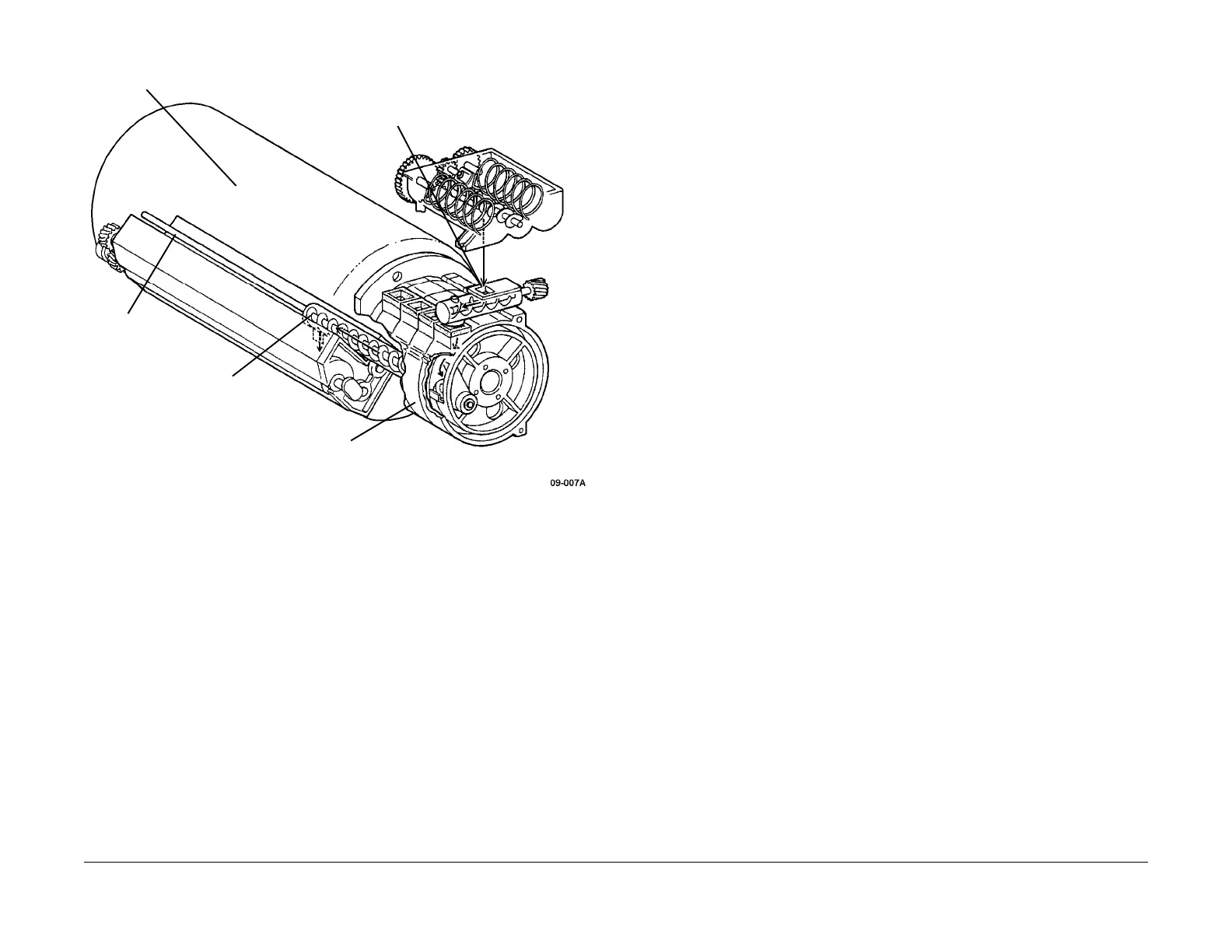

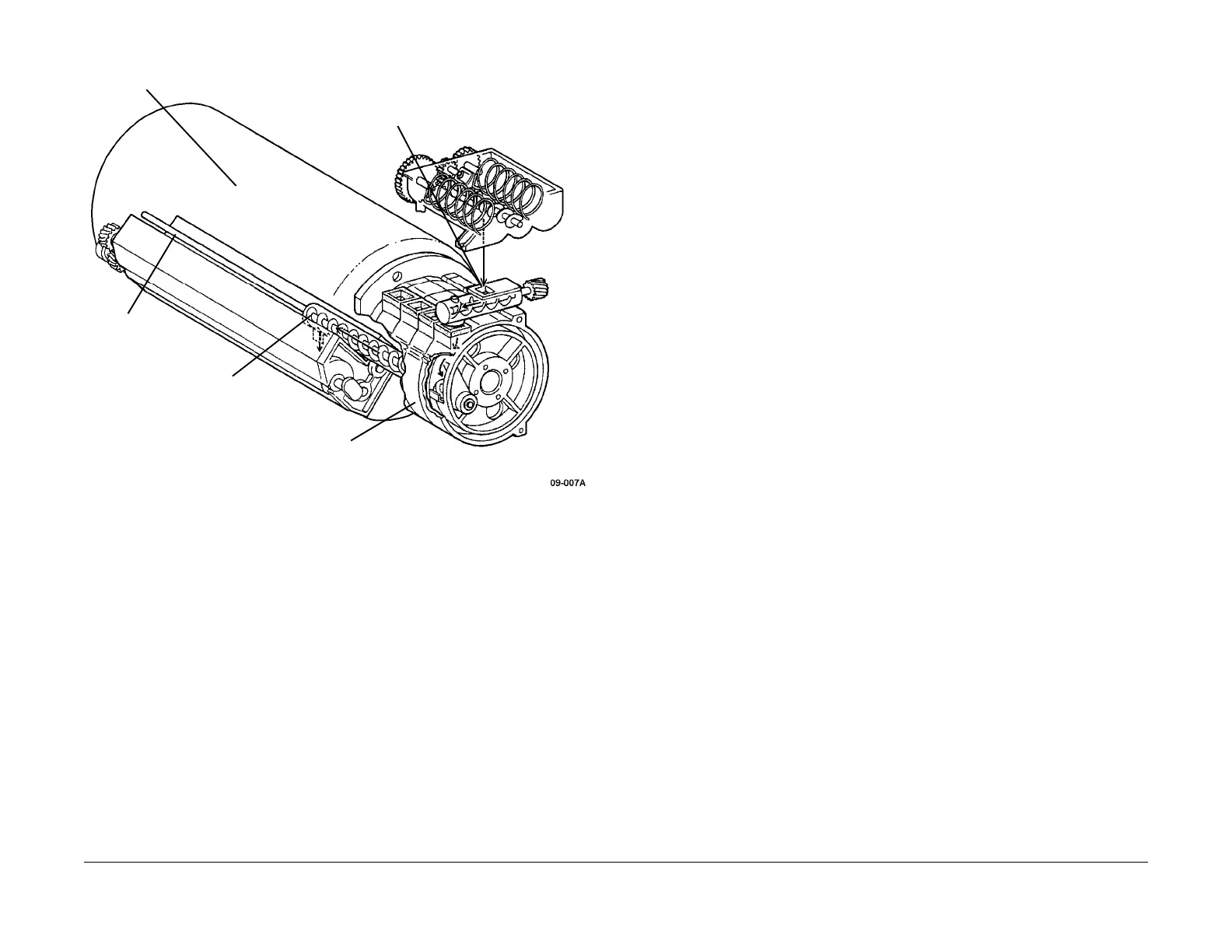

Figure 7 Rotary Dispenser and Developer Housing Assembly (Example)

Trickle System

This machine uses a “Trickle System” for replenishing the developer.

This system increases the

usable life of the Developer Assemblies. It includes the following:

• New developer (toner plus carrier beads) is supplied to the

Developer Housings by the

Toner Supply system.

• Used carrier beads from the Developer Roll are remixed back in with the new developer at

the Developer

Housing.

• Any excess waste carrier beads that accumulates in the Developer Housing is discharged

into a ce

ntral Waste Auger and transported to the Waste Carrier Bottle. This Waste Auger

and Waste Carrier Bottle accepts the excess developer from all four colors.

This system starts with the Toner Cartridges which carry a mixture of both toner and carrier

beads.

The di

fferent colors of developer are transported to the appropriate Developer Housing

within the Developer Rotary Assembly. When the latent image on the Photoreceptor Drum is

developed, the toner is electrostatically attracted to the drum and the metal carrier beads

remain on the magnetic Developer Roll.

The carrier beads are brought back into the Developer

Housing and remi

xed with the existing

developer. New developer is added to the Developer Housing (see Toner Supply) at a rate

determined by readings taken from the ADC patch on the Photoreceptor Drum.

Excess waste carrier beads for each Developer Housing are tr

ickled out automatically through

a shutter gate into a center Waste Auger when the Developer Housing is at 90° above the

development point.

When performing black only copying, the black Dev

eloper Housing needs t

o rotate up to the

90° location to remove the depleted waste carrier beads into the center Waste Auger. This is

done when:

• The copy job is completed

• The Toner Dispense Motor runs continuously for 17 seconds.

Waste Carrier Bottle

The Waste Carrier Bottle receives the waste developer fr

om all four Developer Housings. A

magnetic sensor is used to detect a full Waste Carrier Bottle. The sensor is monitored once

every second. When the waste carrier full status is detected by the sensor five times in succes-

sion, then a “caution” notice (09-423) for the status of

th

is bottle is sent to the User Interface

screen.

The machine monitors both the sensor status and the

rotating time of the Toner Dispense

Motor from this caution status. When a specific accumulated NVM value for the Toner Dis-

pense Motor is reached, then a Waste Carrier Bottle f

ail signal (09-379) is s

ent to the User

Interface.

Toner Supply Control

Toner supply is controlled by the IOT CPU P

WBA, through the IOT Drive and Dispense

PWBAs. The Low Toner Sensor output is routed to an input port on the IOT Drive PWBA,

where it can be read by the CPU on the IOT CPU PWBA. Likewise, the CPU controls a port

output from the IOT Drive PWBA for both the Cartridge and Dispense Motor control lines.

These control lines enable Dispense PWBA circuitry which converts Interlock +24 VDC to 24

VAC, 60 Hz power for the motors. Note that in Figure 9, only the black control and status lines

are shown. The yellow, magenta and cyan circuitry is exactly the same.

DEVELOPER ROTARY

ASSEMBLY

AXEL SHAFT

ROTARY

AUGER

DEVELOPER INLET

ROTARY

DISPENSER

manuals4you.commanuals4you.com

Loading...

Loading...